A low-temperature performance test device and test method for a support heat insulation rod for low-temperature equipment

A technology for testing device and low-temperature performance, which is applied in the direction of measuring device, applying stable tension/pressure to test material strength, strength characteristics, etc. It can solve the problems of not being able to meet the requirements of performance testing and not being able to test heat leakage, etc., and achieve ingenious and reliable structure , the effect of reducing stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

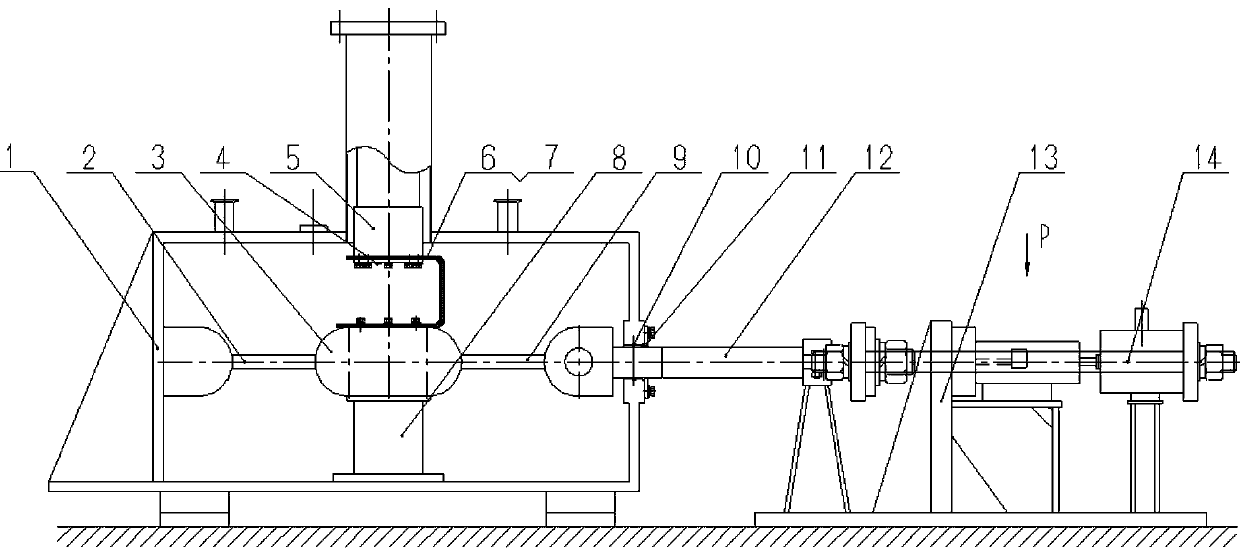

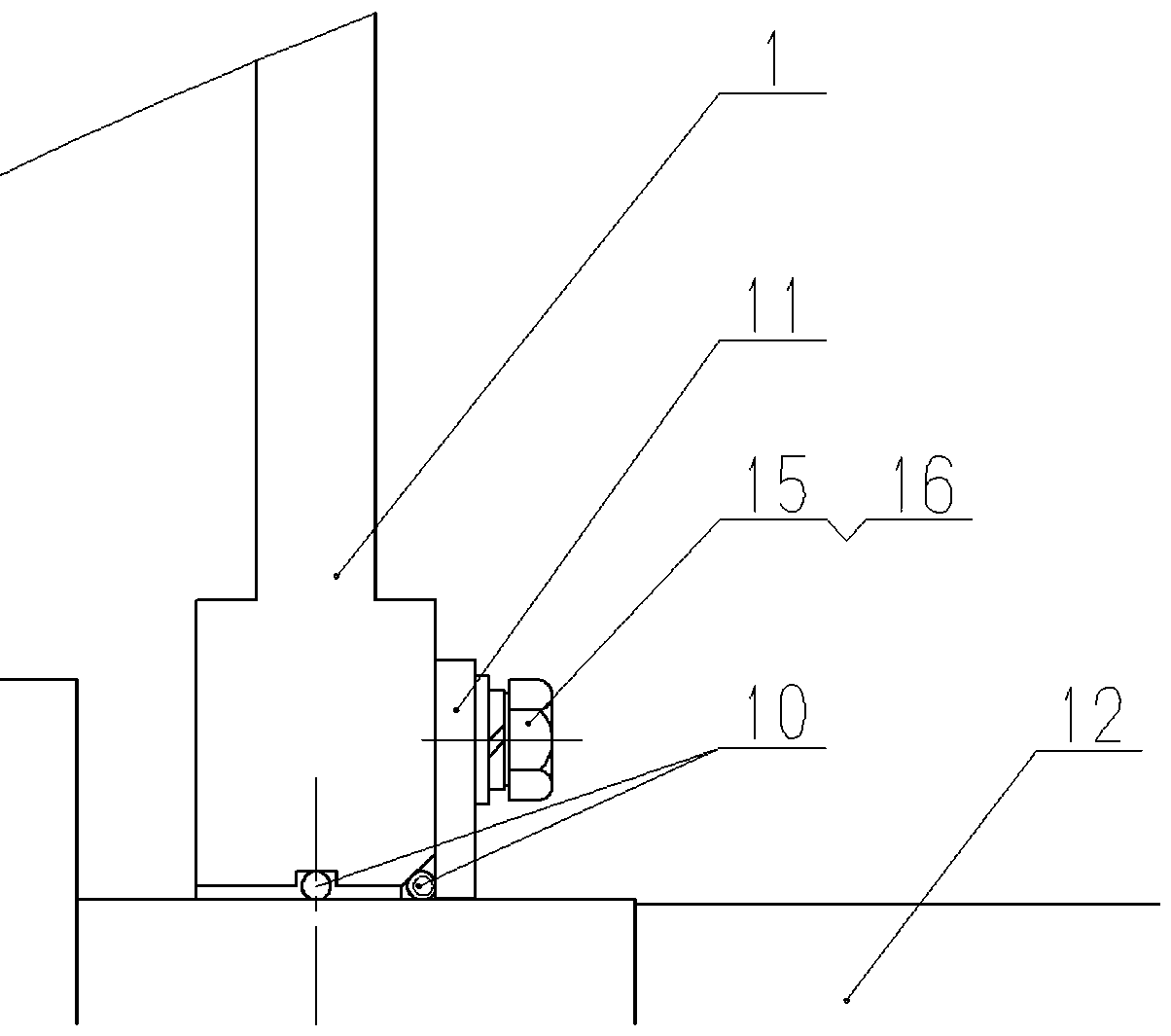

[0029] refer to Figure 1 to Figure 7 As shown, the present invention discloses a low-temperature performance testing device for a support heat insulation rod for low-temperature equipment, including a base 13, a vacuum container 1, an axial installation part and a radial installation part arranged in the vacuum container 1, and the vacuum The container 1 and the base 13 are fixed on the test platform.

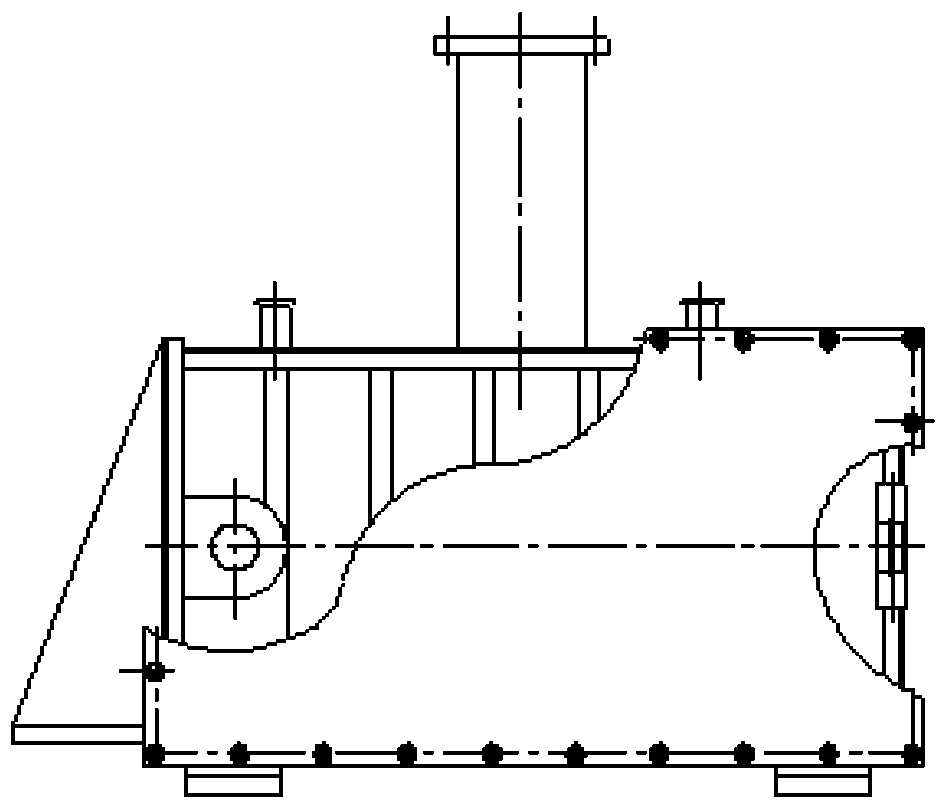

[0030] The vacuum container 1 includes a box body 101 and a cover plate 103, a second O-ring 102 is arranged between the box body 101 and the cover plate 103, and the cover plate 103 is installed through the box body and the cover plate The bolts 104 , the box body and the cover mounting gasket 105 are fixedly connected to the box body 101 . The box body 101 includes a frame 1011, a vacuum joint 1012, an aviation socket 1013 and a refrigerator cold head sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com