Genetic algorithm-based piezoelectric actuator feedforward and closed-loop compound control method and system

A genetic algorithm and composite control technology, applied in the fields of feedforward and closed-loop composite control of piezoelectric ceramic drivers based on genetic algorithms, can solve problems such as asymmetric hysteresis curves of piezoelectric ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

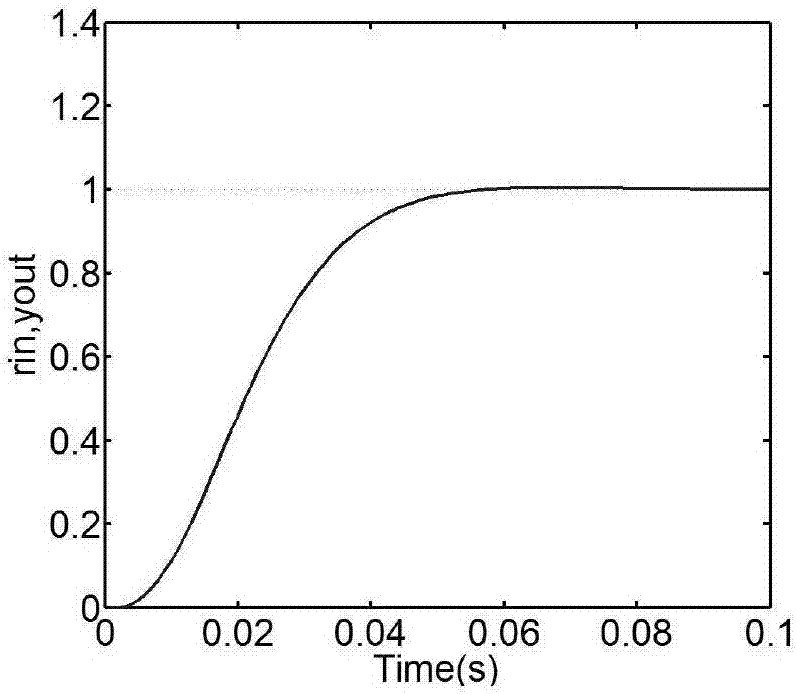

[0095] This embodiment is based on the genetic algorithm-based feedforward and closed-loop composite control method of the piezoelectric ceramic driver, and the expected displacement r(t) of the piezoelectric ceramic driver is input into the feedforward model, and the feedforward model is based on the expected displacement value r(t) Calculate the initial driving voltage u of the piezoelectric ceramic driver ε (t); With the piezoelectric ceramic displacement or the piezoelectric ceramic driver displacement as the feedback signal of the PID controller, the initial drive voltage u is controlled by the PID controller ε (t) Perform error elimination to obtain the driving voltage of the piezoelectric ceramic driver, and use the genetic algorithm to adjust the proportional parameter k of the PID controller p , integral adjustment parameter k i , the differential adjustment parameter k d optimize.

[0096] In this embodiment, the feedforward model is an improved PI hysteresis inve...

Embodiment 2

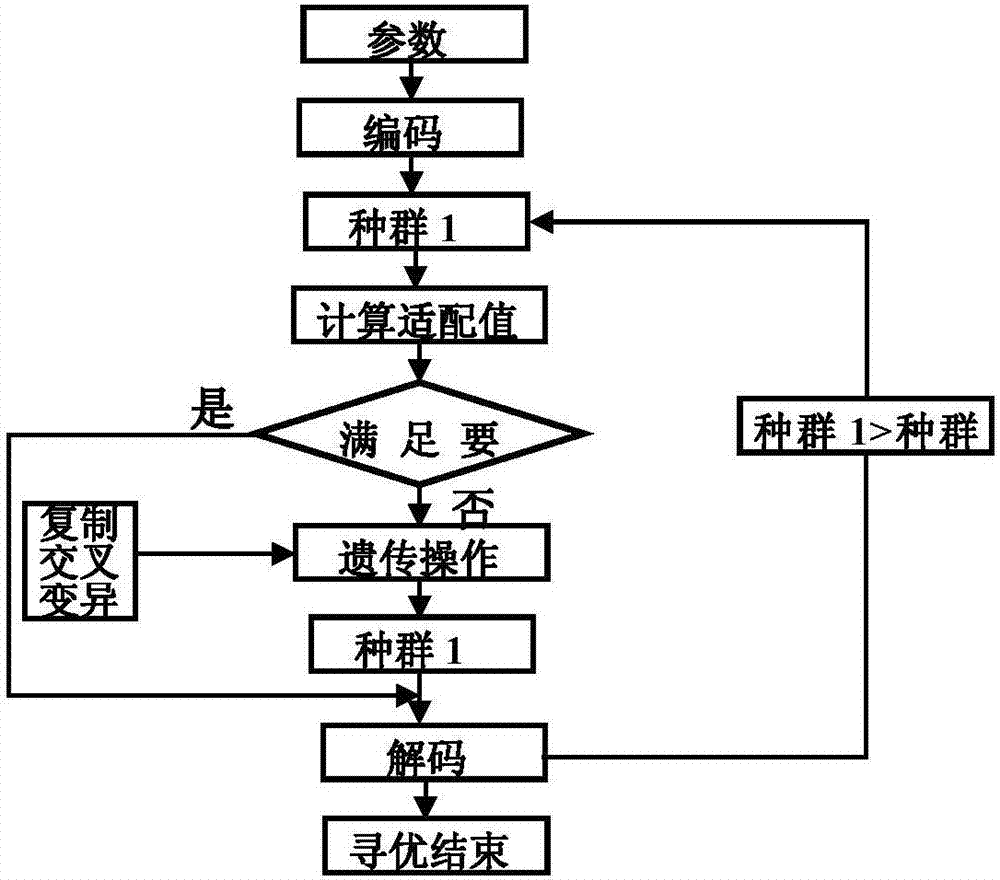

[0163] This embodiment is based on the genetic algorithm-based feed-forward and closed-loop compound control method for piezoelectric ceramic drivers. On the basis of Embodiment 1, the genetic algorithm-based optimization of the proportional adjustment parameter k of the PID controller p , integral adjustment parameter k i , the differential adjustment parameter k d Specifically include:

[0164] S1 respectively determines the proportional adjustment parameter k p , integral adjustment parameter k i , the differential adjustment parameter k d range and encoding length, encode each parameter separately, select a binary string to represent each parameter, and establish a relationship with the parameter;

[0165] S2 randomly generates n individual structures into the initial population p(0);

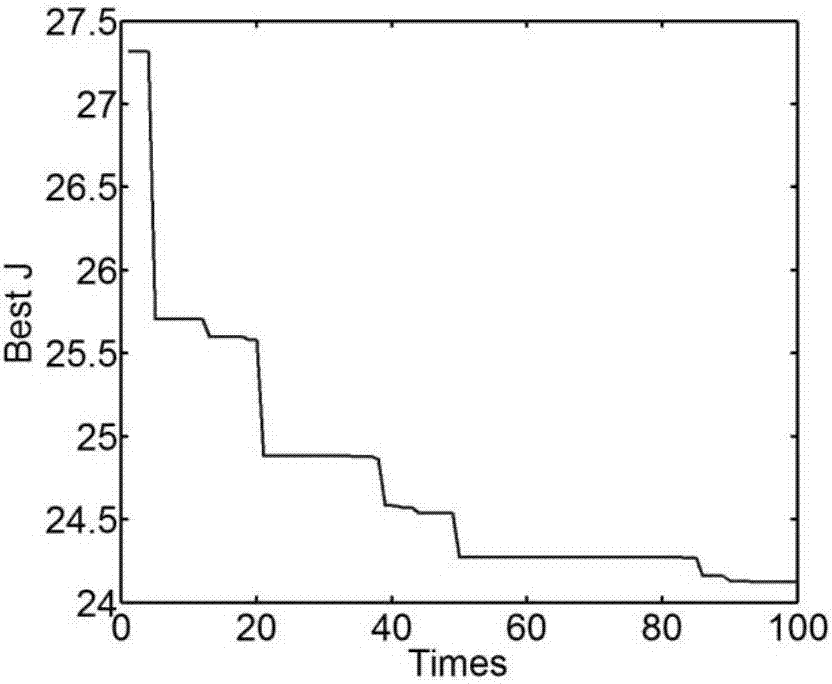

[0166] S3 decodes each of the population into a corresponding parameter value, and substitutes this parameter value into the objective function. After the objective function is determi...

Embodiment 3

[0181] In this embodiment, the feedforward and closed-loop composite control system for piezoelectric ceramic drivers based on genetic algorithms includes: a feedforward model unit, a PID controller, a PID parameter optimization unit, a sensor measurement unit, and a piezoelectric ceramic driver, wherein,

[0182] The feedforward model unit is used to obtain the initial driving voltage u of the piezoelectric ceramic driver according to the input operation of the expected displacement r(t) of the piezoelectric ceramic driver ε (t);

[0183] The sensor measuring unit is used to output the displacement of the piezoelectric ceramic driver, obtain the displacement of the piezoelectric ceramic in the piezoelectric ceramic driver, and use it as a feedback signal for the closed-loop control of the PID controller;

[0184] The PID controller is used to control the initial driving voltage u according to the displacement of the piezoelectric ceramic driver and the displacement of the pie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com