Noise elimination V-type ball valve with combined hole plates

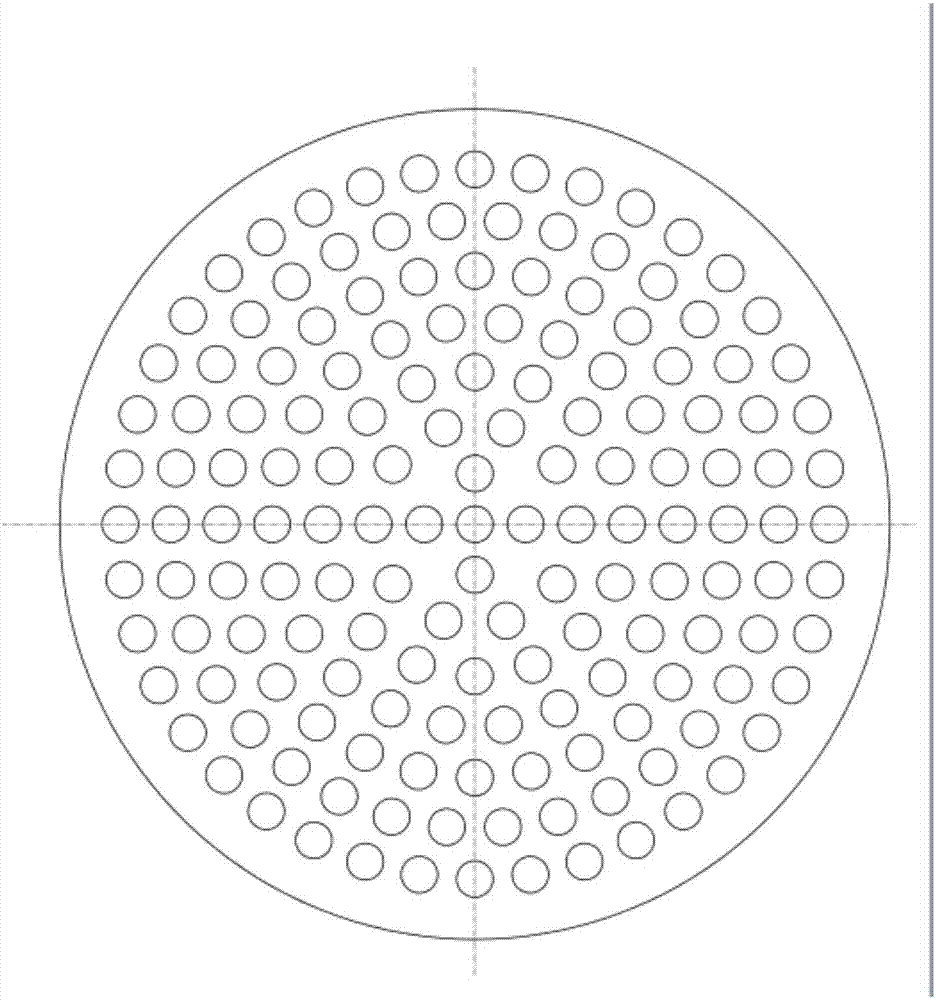

A combination hole and ball valve technology, applied to valve details, valve devices, cocks including cut-off devices, etc., can solve problems such as fluid excitation, high noise, fluid excitation, high noise that have not been discussed in depth, and achieve good results Noise reduction ability, noise reduction, and overall compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

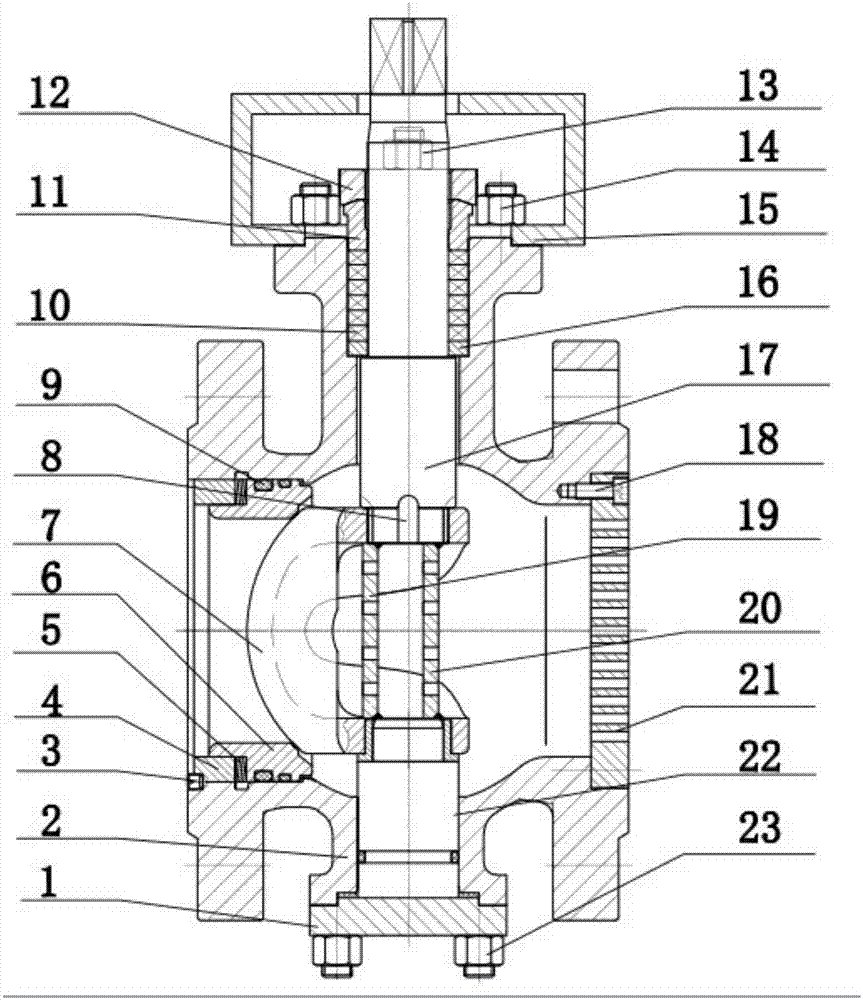

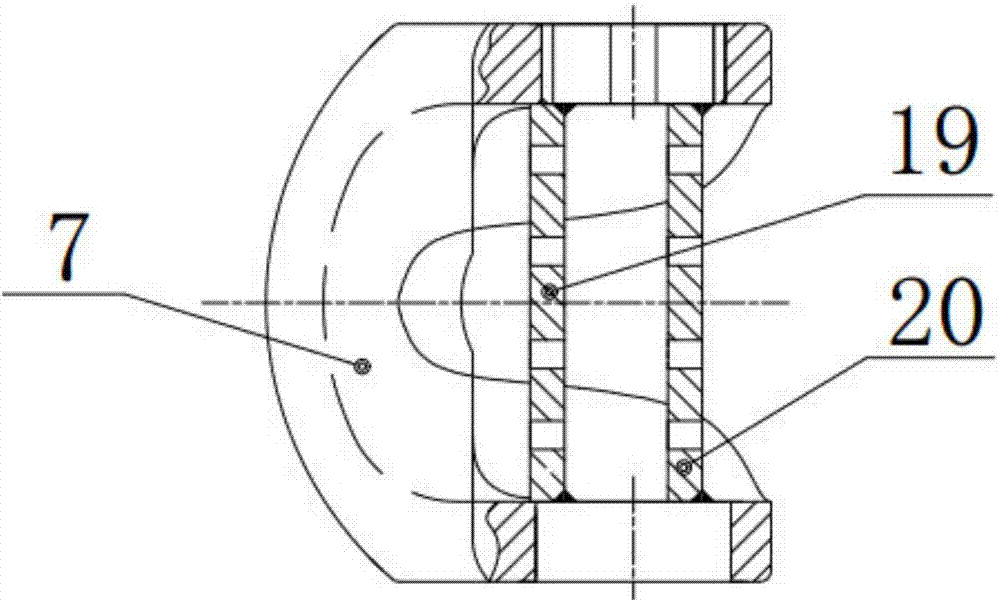

[0007] Such as figure 1 As shown, the multi-hole noise-absorbing V-type ball valve of the present invention includes a valve body 2, and the valve body 2 and the disc spring gland 4 are fastened together with locking screws 3, and the disc spring gland 4 is tightened by the disc preload spring. 5 Press the valve seat support ring 6 to further ensure the sealing performance between the valve seat support ring 6 and the valve core 7, the valve body 2 and the valve seat support ring 6 are sealed by the O-ring 9, and the valve stem 17 passes through The spline 8 drives the valve core 7 to rotate, the valve core 7 contacts with the valve seat supporting ring 6 to form a sealing surface, the bolt and nut parts 13 press the packing gland 12 and the valve body 2 together, and the packing gland 12 passes through the packing bushing 11 The packing 10 is pressed tightly, the bolt and nut parts 14 press the support frame 15 and the valve body 2 together, the packing gasket 16 isolates the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com