Gear reducer optimization method based on FOA (FruitFly Optimization Algorithm)

A technology of gear reducer and optimization method, applied in the direction of design optimization/simulation, instrument, calculation, etc., can solve the problem of non-optimization of design parameters matching, and achieve the effect of ensuring safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0065] A kind of gear reducer optimization method based on FOA algorithm of the present invention,

[0066] S1. Taking the two-stage gear reducer as the design research object, establish a mathematical model with the minimum volume of the two-stage gear reducer as the optimization goal;

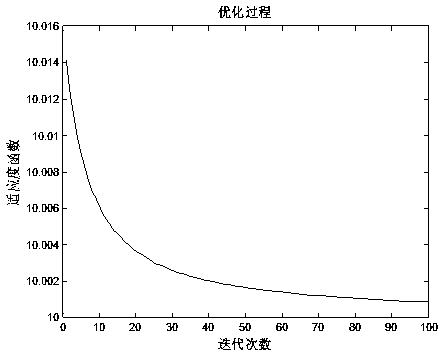

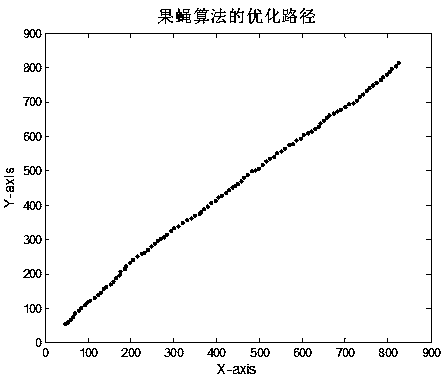

[0067] S2. Combining with the fruit fly optimization algorithm, introducing the correction factor β into the fruit fly optimization algorithm to obtain a modified fruit fly optimization algorithm, and then optimizing the mathematical model established in step S1.

[0068] The specific implementation process of the step S1 is as follows,

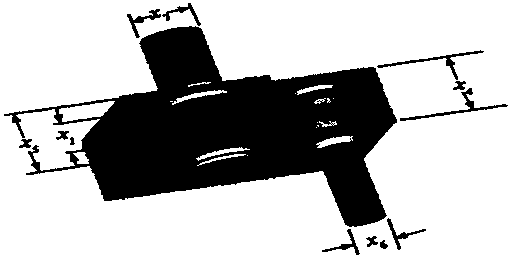

[0069] S11. Taking the two-stage gear reducer as the design research object, it has 7 design variables, including the gear face width x 1 , tooth mold x 2 , number of pinion teeth x 3 , first shaft bearing spacing x...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com