Cable laying and fixing apparatus

A cable laying and fixing device technology, applied in cable installation, ground cable installation, substation/switch layout details, etc., can solve the problems of messy overall layout, affecting the moisture-proof effect of cabinets, etc. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

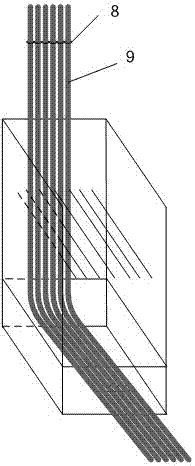

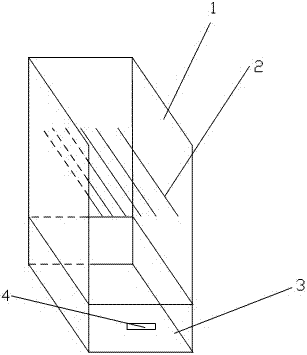

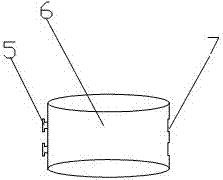

[0020] like Figure 1-3 As shown, a cable laying fixing device includes a cable branch trench and a cable fixing accessory. The cable branch trench is used for laying cables, and the cable fixing accessory is used to fix the cable. The upper side of the cable branch trench is not closed, and the cable branch trench There is a fixed cable partition, and there are a number of gaps evenly distributed from left to right in the fixed cable partition for the insertion and fixing of cables. The door panel, the cable fixing accessory includes a fixed ring sleeve, a through hole for connecting with the cable is provided in the middle of the fixed ring sleeve, a buckle is provided on one side of the fixed ring sleeve, and a slot matching the buckle is provided on the other side. The fixed ring sleeve is connected with the card slot of the adjacent fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com