Automatic cutting bed and cutting processing method with cloth clamping dragging and precise positioning

A technology of precise positioning and cutting bed, applied in the cutting of textile materials, textiles and papermaking, etc., can solve the problems of labor and time, long assembly cycle, low processing efficiency, etc., to improve the utilization rate of fabrics and improve the accuracy of laying The effect of reducing the degree and labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to facilitate a better understanding of the purpose, structural features, and effects of the present invention, the present invention will now be described in further detail in conjunction with the accompanying drawings and specific embodiments.

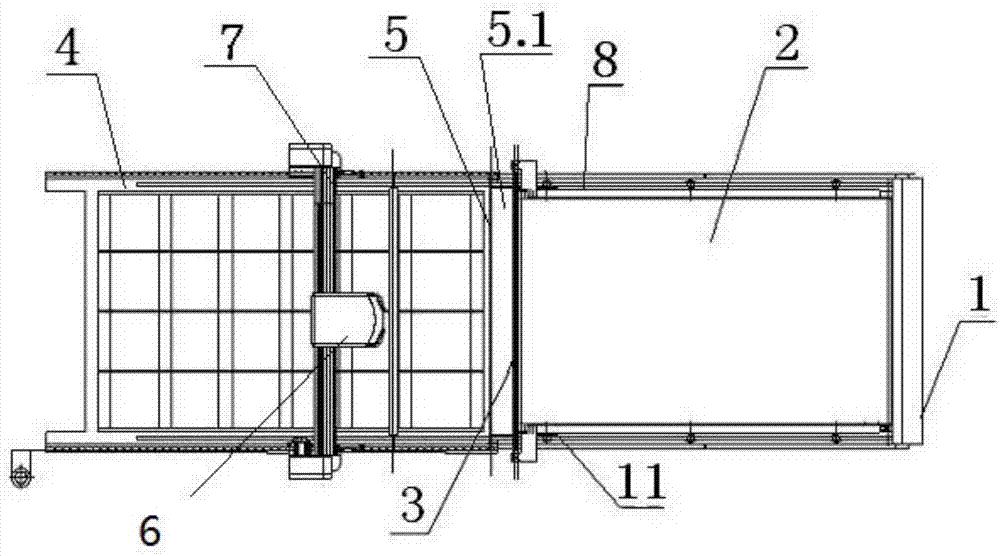

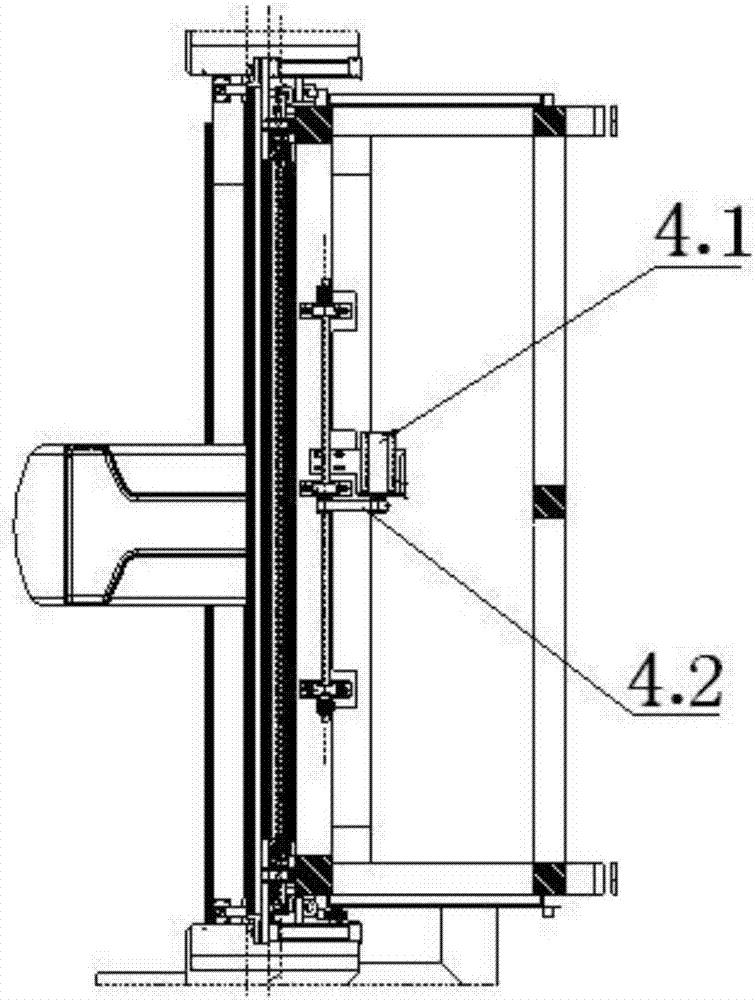

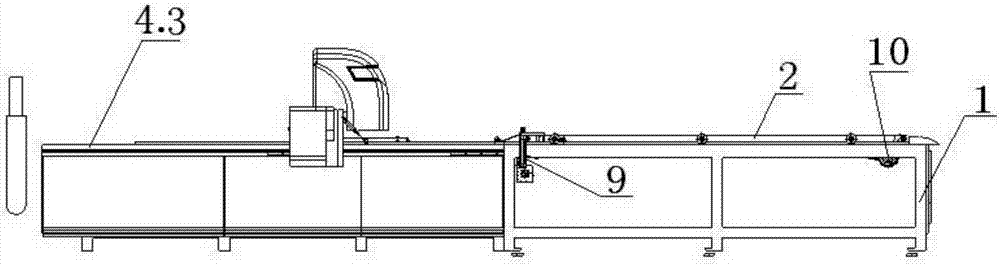

[0036] The automatic cutting bed designed by the present invention for dragging and precisely positioning the cloth includes a cutting bed 1 and a pick-up table 4, and the cutting bed 1 is provided with a drive module, a reducer module, a numerical control module, and a transmission module. The cutting bed 1 is provided with a split vacuum gas pump, and the cutting bed 1 is fixedly provided with a brown felt conveying table 2, and the picking table 4 is set higher than the cutting bed 1, and the picking table 4 and The joint of the cloth output end of the cutting bed 1 is provided with a cloth clamping lower base plate 5, which is connected with an inclined plane 5.1 at an angle of 65-75° to the horizontal plane, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com