Self-walking wheat and rice cutting, sunning and laying machine

A self-propelled, laying technology, used in harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of congestion in conveying and laying, irregular straw laying, and unstable gap between moving and fixed knives. To achieve the effect of convenient operation, novel overall structure and improved cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

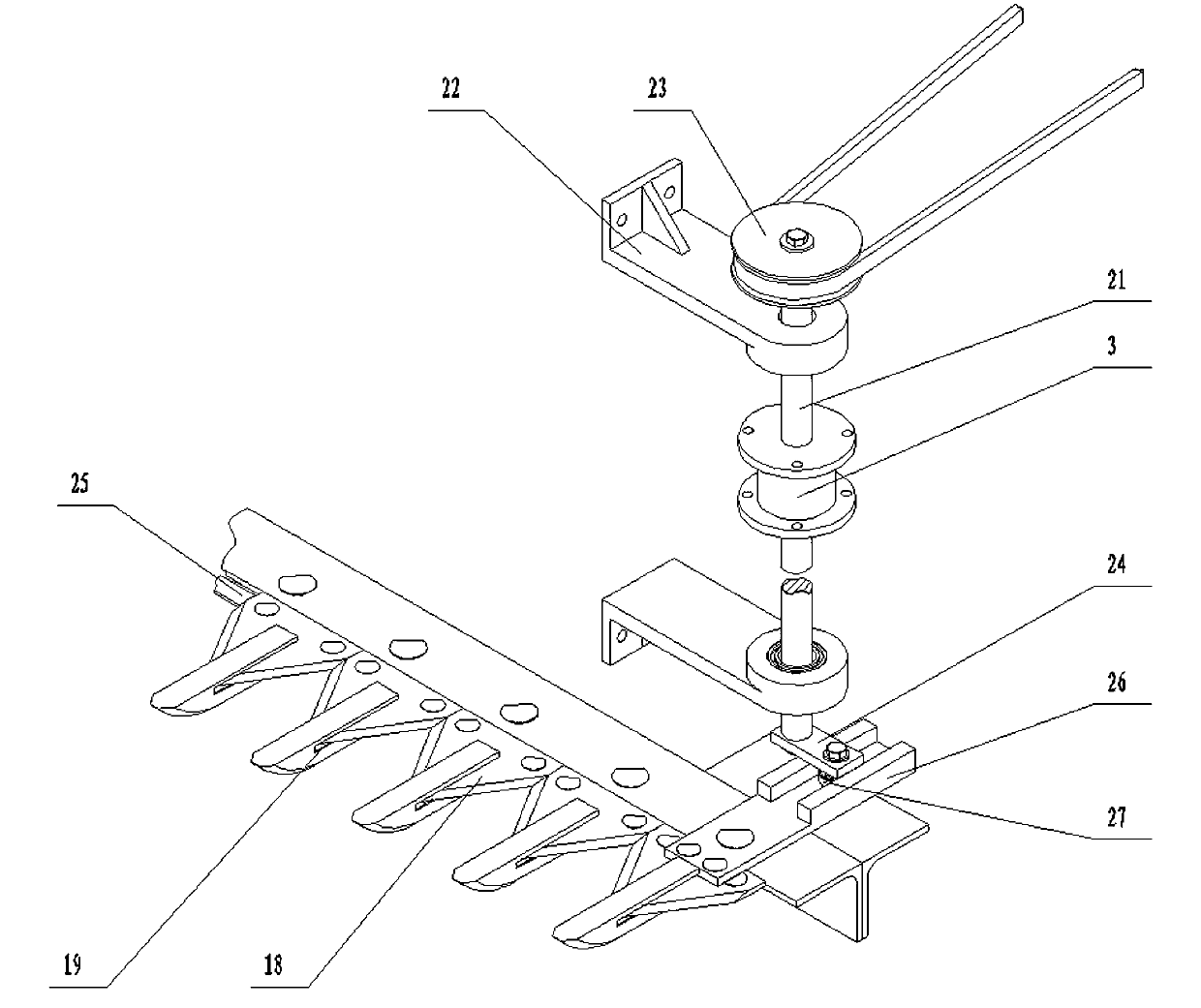

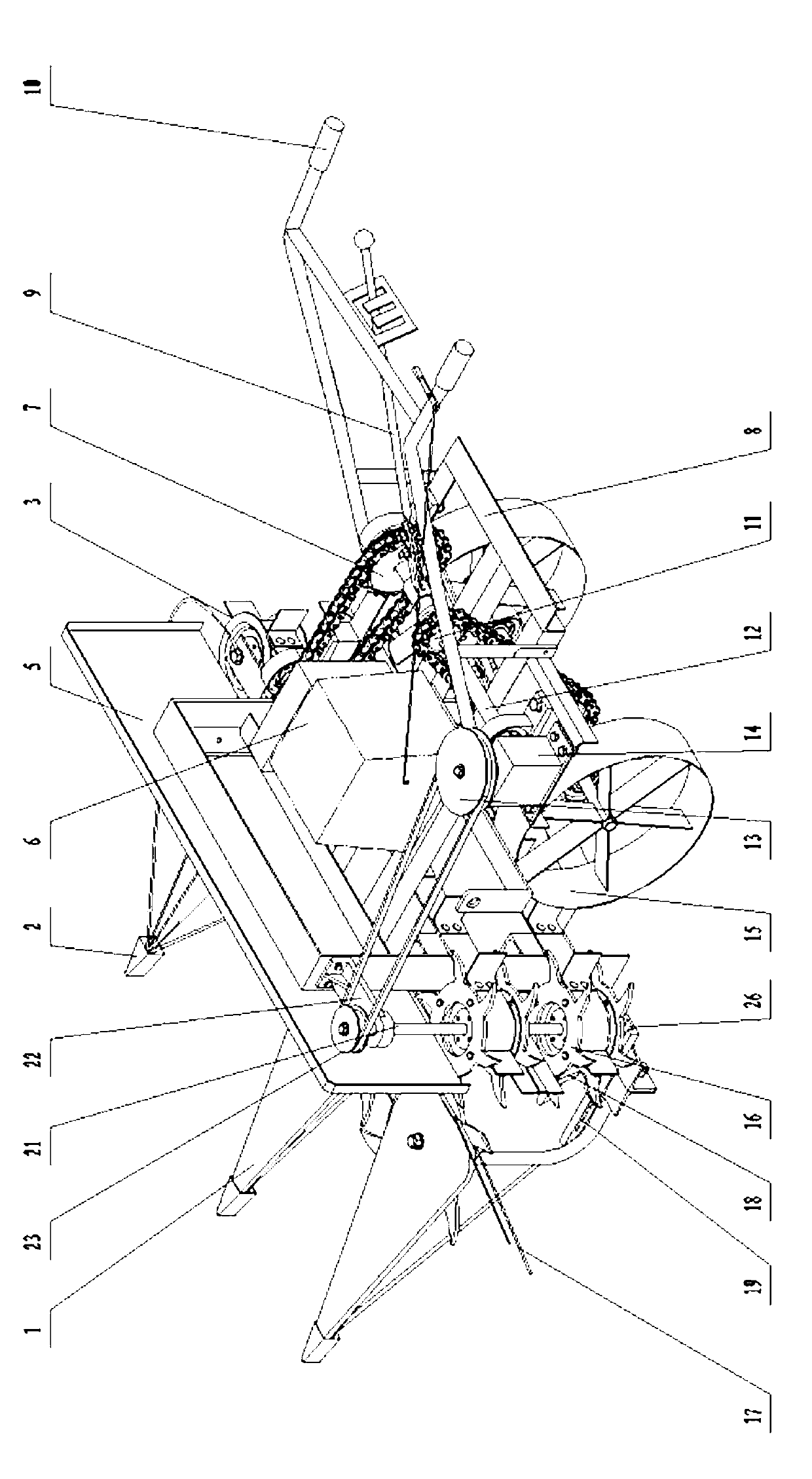

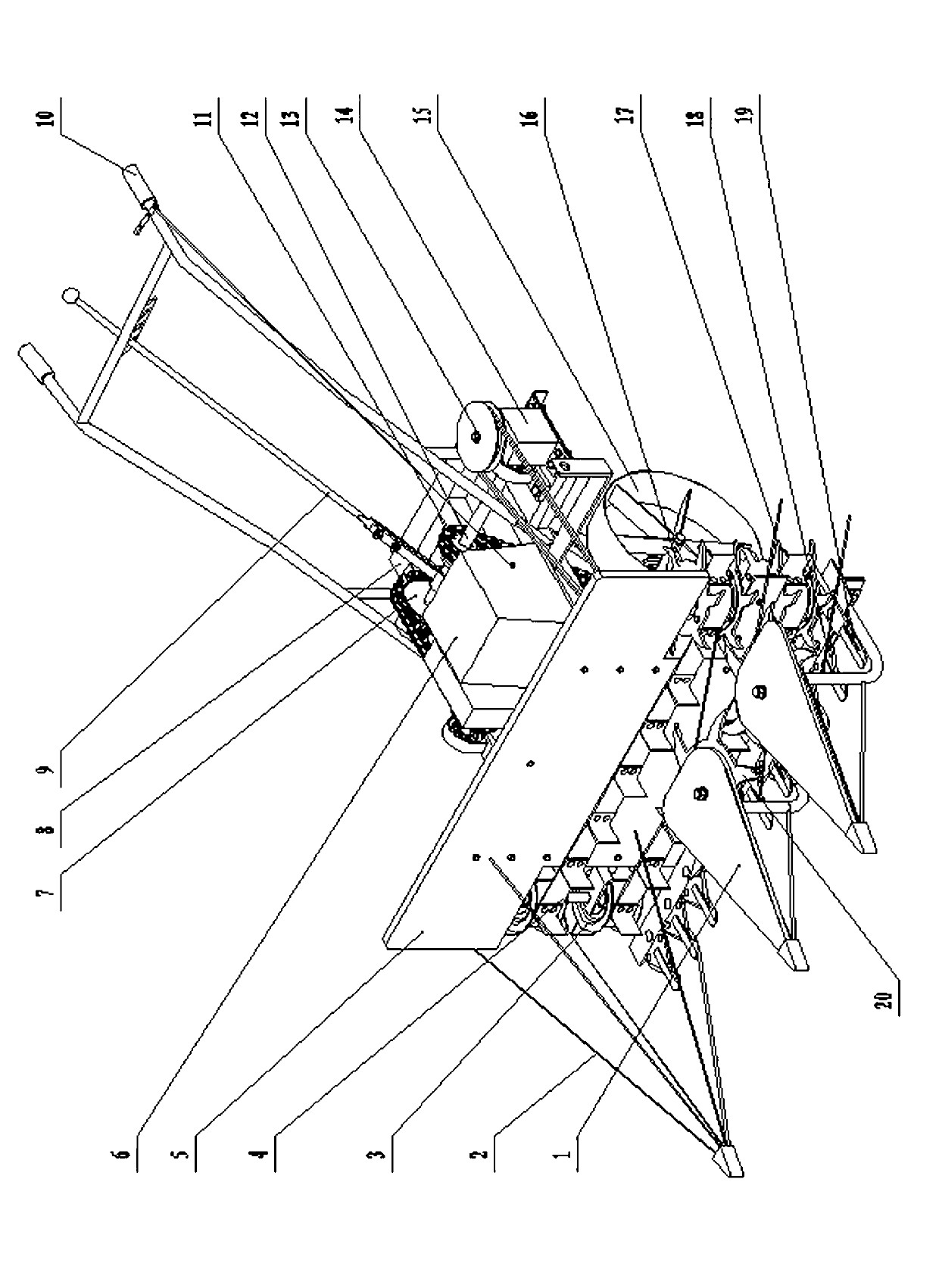

[0017] The present invention comprises frame 8, and frame 8 front part is equipped with cutting mechanism, and the right side of frame 8 front part is equipped with crop divider 2, and frame 8 front part left side is equipped with grain supporter 1, and frame 8 middle part is equipped with. Conveying and laying mechanism and transmission mechanism are arranged, and frame 8 rear portion is provided with traveling mechanism; Among them, the transmission mechanism is equipped with a power distribution shaft 12 above the rear part of the frame 8, the right end of the power distribution shaft 12 is connected to the power input sprocket 7, the power input sprocket 7 is connected with the engine 6 through a chain, and the middle part of the power distribution shaft 12 is equipped with a walking drive. The output sprocket 11, the left end of the power distribution shaft 12 is connected with the reversing gear box 14, and the reversing gear box 14 is connected with the horizontal output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com