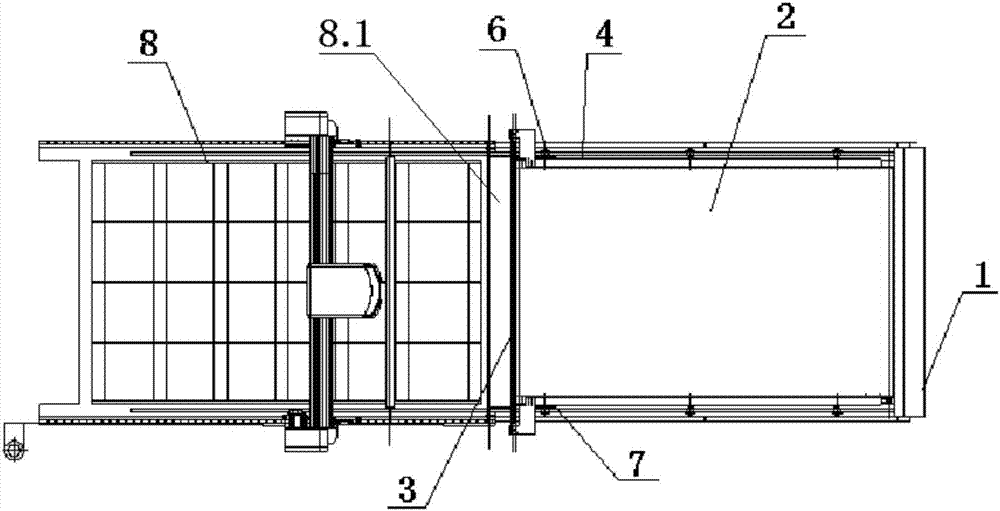

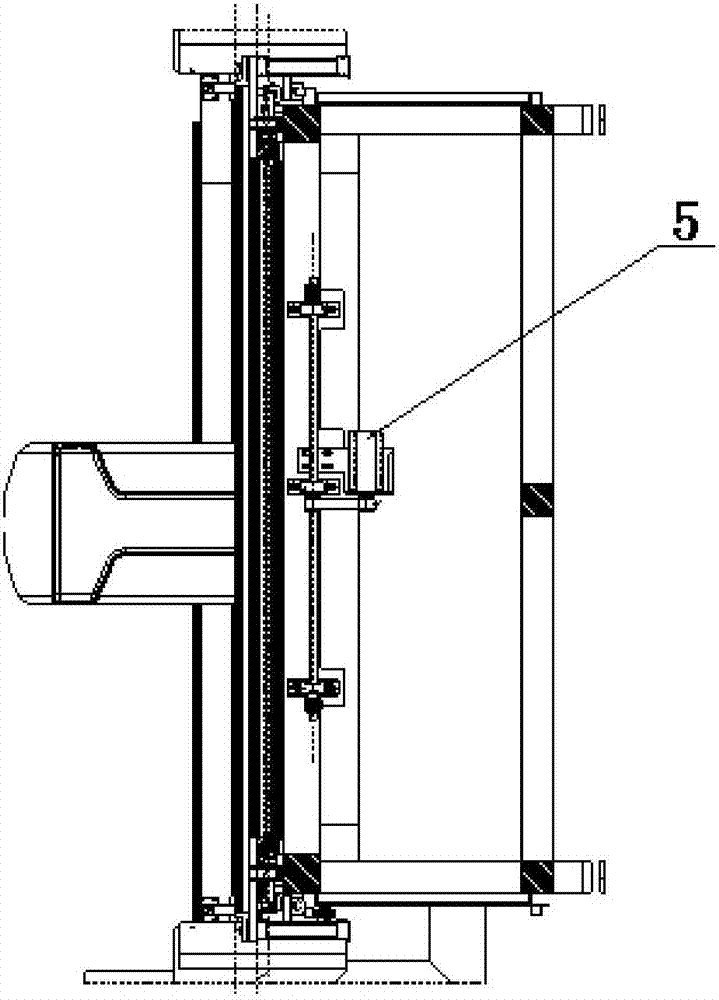

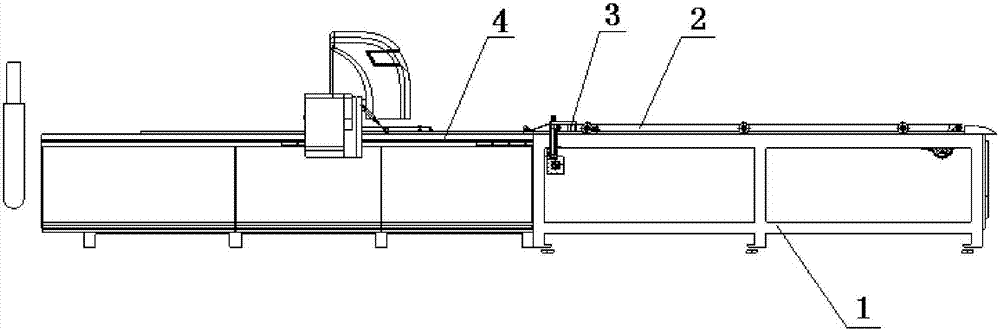

A new intelligent cutting machine capable of shoveling cloth and its cutting processing method

A cutting machine, a new type of technology, applied in the cutting of textile materials, metal processing, textiles and papermaking, etc., can solve the problem that the cutting machine can not be collected and spread at the same time, the production efficiency needs to be further improved, and the long-distance transportation and installation are difficult. and other problems, to achieve the effect of improving the utilization rate of fabrics and cutting quality, saving the amount of steel used, and reducing the design cycle and difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045]Below with cutting 180 layers of knitted fabrics, 70 meters long, the cloth of wide 2 meters is embodiment, illustrates the device using process of the present invention:

[0046] (1) Spreading, the worker puts all the knitted fabrics to be cut on the spreading table.

[0047] (2) Loading, put the knitted surface on the pick-up table, and lay it neatly on the effective cutting platform.

[0048] (3) Lay the film, open the transparent protective film on the reel, and cover all the knitted fabrics to be cut on the pick-up table.

[0049] (4) Controlled by the numerical control system, the parameters and specifications of the cutting pieces of the required size are set.

[0050] (5) Vacuum adsorption, set the vacuum air pump and the number of motor revolutions, and adsorb 180 layers of knitted fabrics on the pick-up table.

[0051] (6) For precision cutting, start the cutting platform, move the intelligent head to the starting point of the effective cutting platform, set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com