A powder bed device for laser additives and its laser additive method and application

A laser additive and powder bed technology, applied in the direction of additive processing, process efficiency improvement, additive manufacturing, etc., can solve the problems of metal powder waste, substrate heat deformation, etc., to reduce the actual amount, improve substrate deformation, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

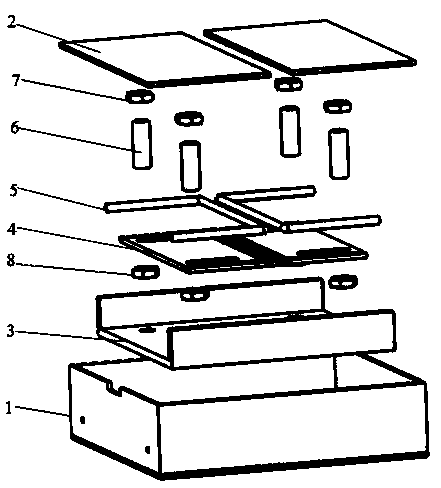

Image

Examples

Embodiment 1

[0071] The equipment of the embodiment of the present invention adopts Nd:YAG laser wavelength 1.06um, the focal length of the focusing lens is 80mm, the thickness of the substrate is 6mm, the protective gas used in the experiment is Ar gas, the substrate material is Q235, 316L stainless steel powder, and the powder particle size is 500 mesh , the selected parameters are shown in Table 1 and Table 2. Different laser powers and different scanning speeds are used for single-layer and single-pass forming, and the forming corresponds to Figure 11 , Figure 12 .

[0072] Table 1

[0073]

[0074] Table 2

[0075]

[0076]

Embodiment 2

[0078] The equipment of the embodiment of the present invention adopts Nd:YAG laser wavelength 1.06um, the focal length of the focusing lens is 80mm, the thickness of the substrate is 6mm, the protective gas used in the experiment is Ar gas, the substrate material is Q235, 316L stainless steel powder, and the powder particle size is 500 mesh , the selected parameters are shown in Table 3. The distance between the centerlines of the two melting channels is 0.4mm, and two-layer multi-pass forming is performed, and the results correspond to Figure 13 shown.

[0079] table 3

[0080]

Embodiment 3

[0082] The equipment of the embodiment of the present invention adopts Nd:YAG laser wavelength 1.06um, the focal length of the focusing lens is 80mm, the thickness of the substrate is 6mm, the protective gas used in the experiment is Ar gas, the substrate material is Q235, 316L stainless steel powder, and the powder particle size is 500 mesh , the selected parameters are shown in Table 4. The distance between the centerlines of the two melting channels is 0.4mm, and five layers and three passes are formed, and the results correspond to Figure 14 shown

[0083] Table 4

[0084]

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com