Automatic household appliance bottom case production equipment

A technology for producing equipment and household appliances, applied in the field of automation, can solve the problems of low production efficiency of the bottom case of household appliances, reduced quality of the bottom case of household appliances, poor accuracy, etc., and achieve the effect of improving production efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

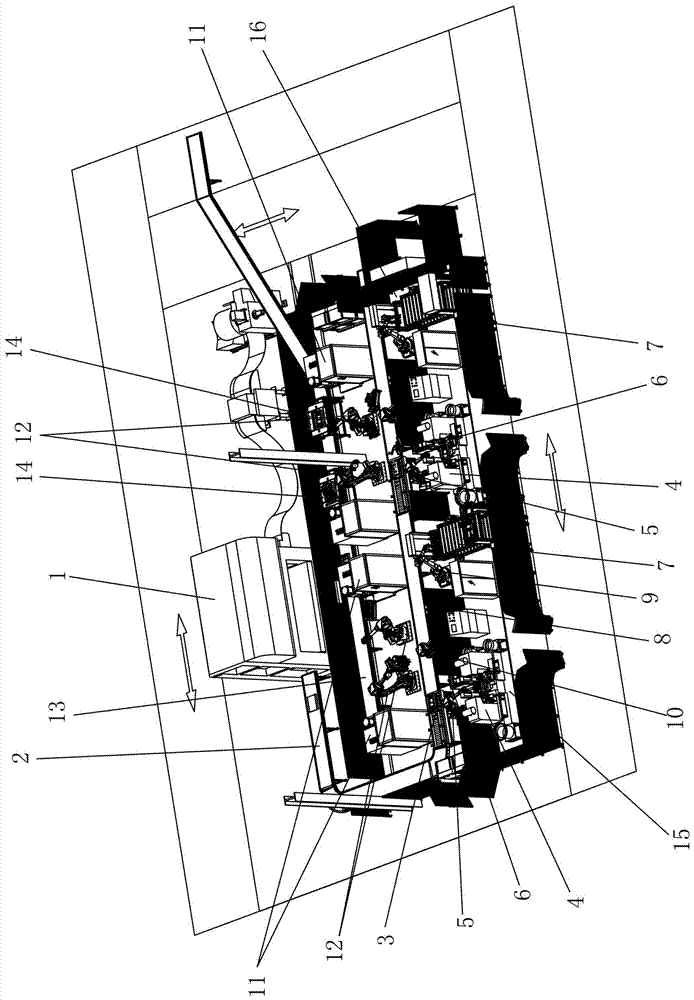

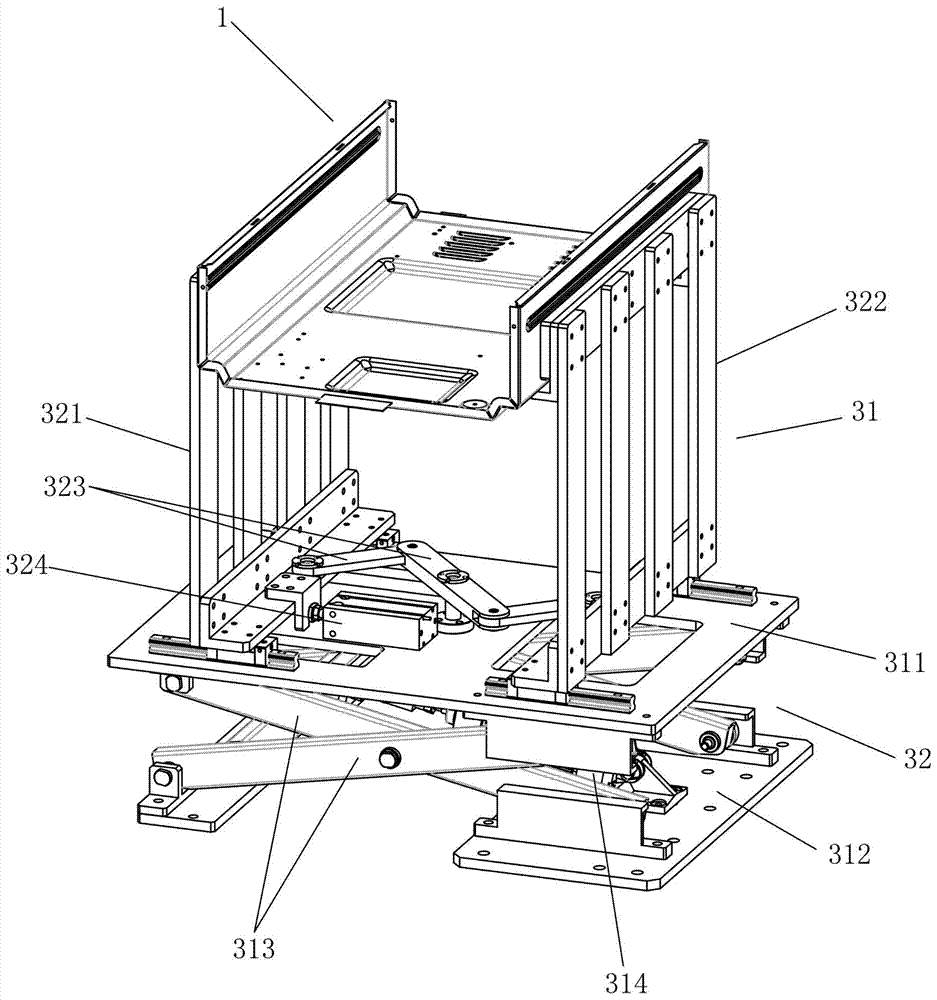

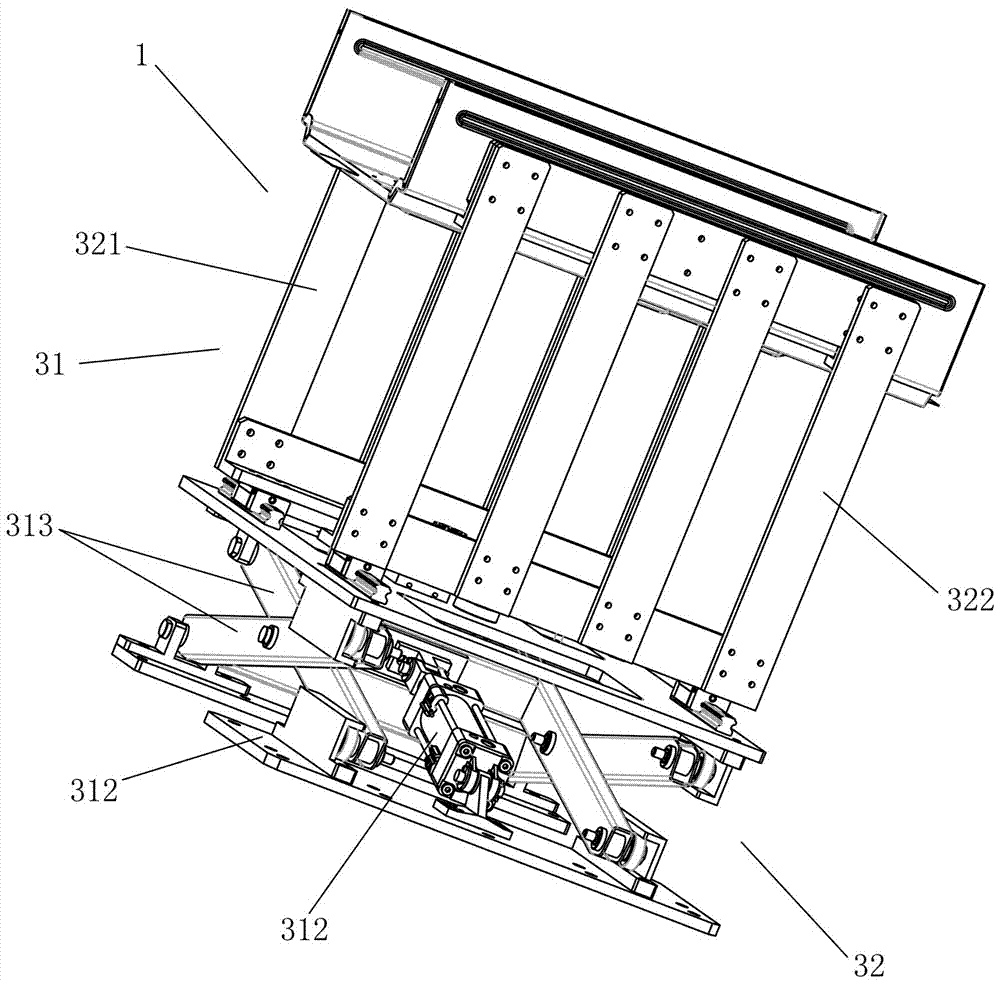

[0044] Example, combined with Figure 1 to Figure 23 As shown, an automatic production equipment for bottom shells of home appliances, including a bottom plate stamping device 1 for stamping metal sheets into a bottom plate, a bottom plate conveyor belt 2 for transporting the bottom plate, and a bottom plate lifting and positioning device 3 for lifting or positioning the bottom plate , the lug welding device 4 for welding the lugs on the base plate, the first clamping robot arm 5 for clamping the base plate to the lug welding device 4 for welding, and the positioning platform 6 for positioning the base plate with lugs, The side plate feeding device 7 for conveying the side plate, the side plate turning platform 8 for turning over the side plate, the second clamping robot arm 9 for clamping the side plate to the side plate turning platform, for assembling the side plate and The assembly robot arm 10 of the bottom plate with lugs is used to weld the side plate to the side plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com