Assembly and detection integrated system based on vision sensing technology

A visual sensing and assembly detection technology, applied in packaging, liquid bottling, liquid processing, etc., can solve problems such as low detection efficiency and inability to accurately control the filling volume of bottled beverages, so as to improve production efficiency and reduce misjudgment of recognition Probability, the effect of reducing the cost of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

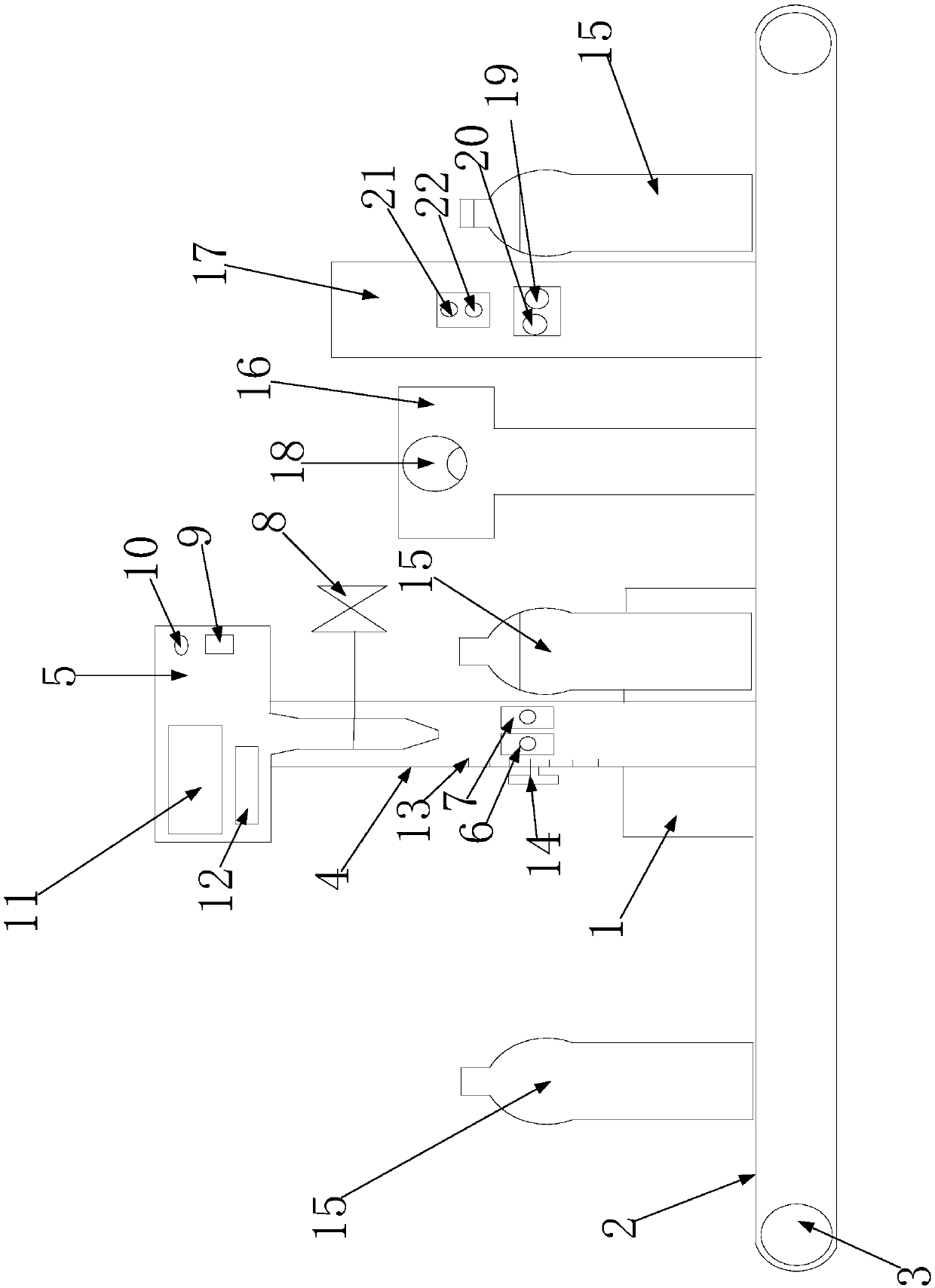

[0022] Such as figure 1 As shown, the integrated assembly and inspection system based on visual sensing technology includes a workbench, on which a processor 1, a conveyor belt 2, and a conveyor motor 3 matching the conveyor belt 2 are arranged, and the sides of the conveyor belt 2 are sequentially arranged along the conveying direction The first support rod 4, the second support rod 16 and the third support rod 17, the filling device 5 and the capper 18 are arranged in turn along the conveying direction above the conveyor belt 2, and the filling device 5 and the first support rod 4 are away from the conveyor belt 2, the capper 18 is connected to the end of the second support rod 16 away from the conveyor belt 2, the sensor assembly and the second solenoid valve 14 are arranged on the first support rod 4, and the second solenoid valve 14 is connected to the The sensor assembly is connected, and the sensor assembly includes a first ultrasonic sensor 6 and a first distance measu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com