Construction device and construction method of wall formwork tension bolts

A technology for pulling bolts and construction devices, which is used in the connection of formwork/formwork/work frame, the preparation of building components on site, construction, etc. Slurry leakage and other problems, to achieve the effect of improving the reuse rate, easy disassembly, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

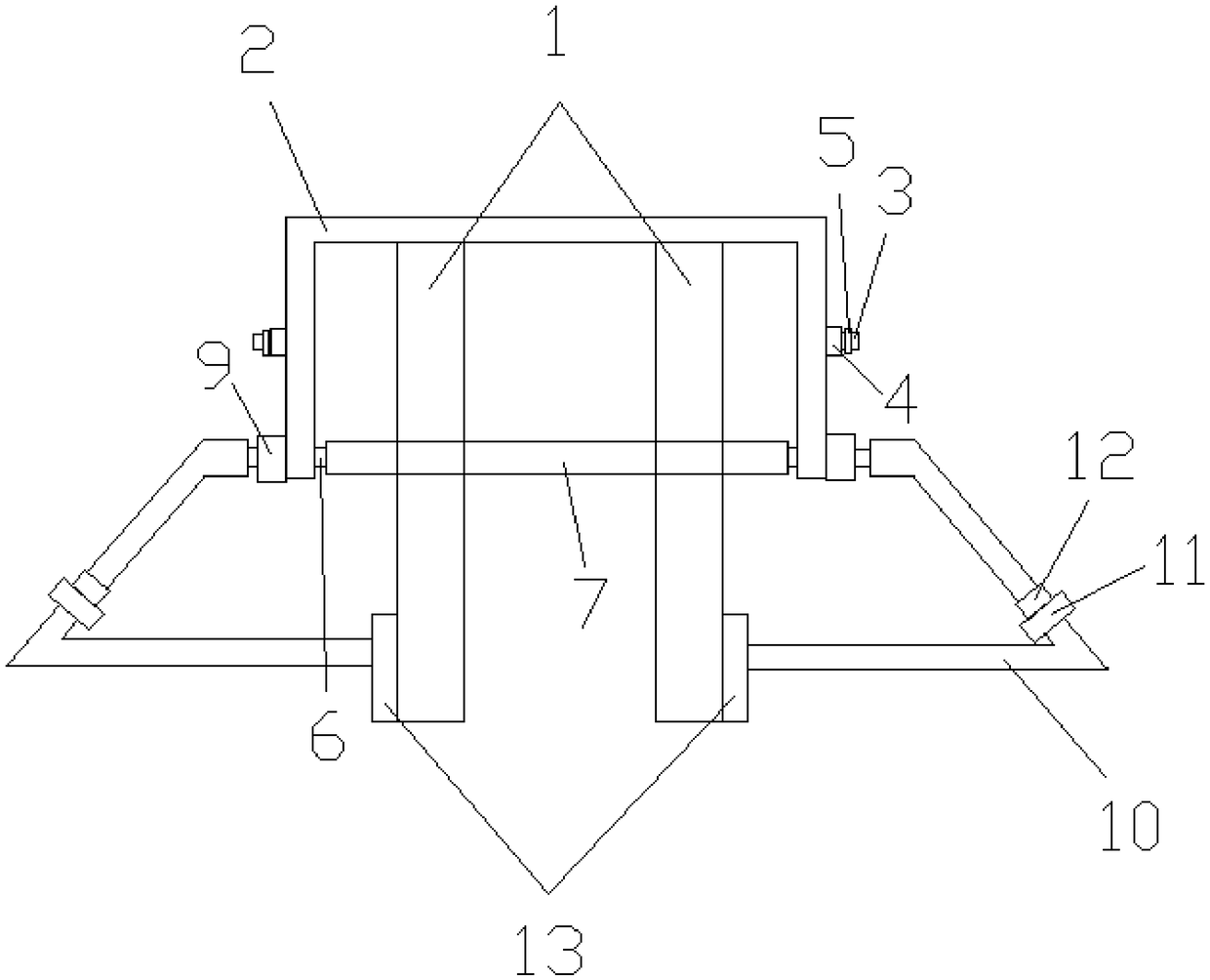

[0030] see Figure 1 to Figure 4 , the construction method of the wall formwork tension bolts, including the following steps:

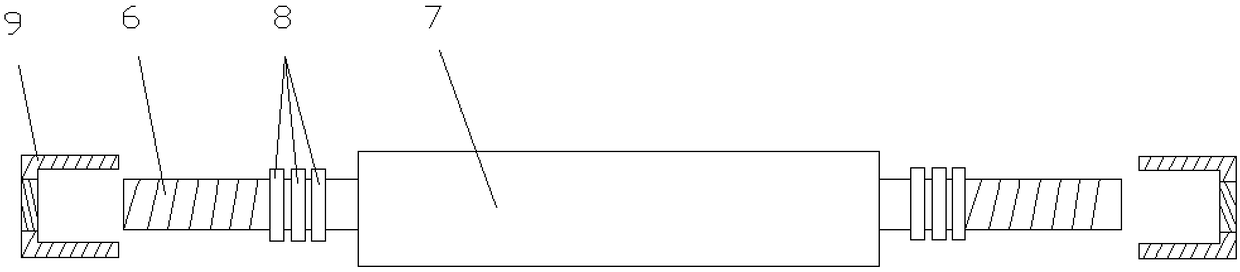

[0031] (1) Set two parallel formworks 1 at the position where the wall body will be poured, pass the sleeve 7 through the formwork 1, the sleeve 7 can fix the formwork 1, and prevent the formwork 1 from falling apart before the lifting fixture 2 , several clamps 2 are hoisted above the formwork 1, the clamps 2 can fix the formwork 1 to increase the stability, and can also prevent the compression capacity of the formwork 1 from being enhanced when pouring concrete, prevent the mold from bursting, and use the fixed Rod 4 connects the fixing bolts 3 on the clamp in twos, and then tightens the fixing nut 5 to fix the fixing bolt 3 to fix the fixing rod 4, through the connection of the fixing bolt 3, fixing rod 4 and fixing nut 5 Cooperation can prevent the clamp 2 from sliding back and forth above the template 1, reducing the instability of the entire de...

Embodiment 2

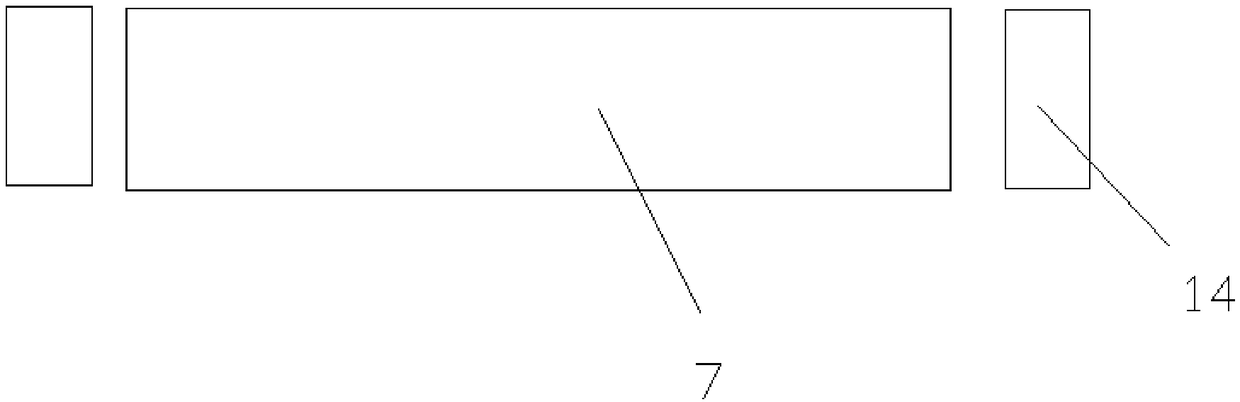

[0041] see Figure 1 to Figure 4 , the present invention also provides a wall formwork pull bolt construction device, comprising a sealing steel plate 13, an angle steel pipe 10, a sleeve 7, a steel bar 6, several clamps 2 and a formwork 1, and the clamps 2 are arranged on the side of the formwork 1 Above, the clamp 2 can fix the formwork 1 to increase the stability, and prevent the compression capacity of the formwork 1 from being enhanced when pouring concrete, preventing mold explosion. The sleeve 7 of the clamp 2 is located on the The inner side of the clamp 2, the steel bar 6 can pass through the clamp 2 and the template 1 and pass through the sleeve 7, the two ends of the steel bar 6 are provided with the angle steel pipe 10, through the angle steel tube 10 and the steel bar The triangular structure formed by the cooperation of 6 can greatly improve the stability and safety of the whole device. The bottom of the angle steel pipe 10 is provided with a sealing steel plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com