Finned-tube hot air gas furnace

A gas-fired hot-blast stove and fin-and-tube technology, which is applied in the directions of air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problem of low heat exchange efficiency of hot blast stoves, high product use costs, and high energy consumption of hot blast stoves. and other problems, to achieve the effect of promoting air mobility, improving utilization rate, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

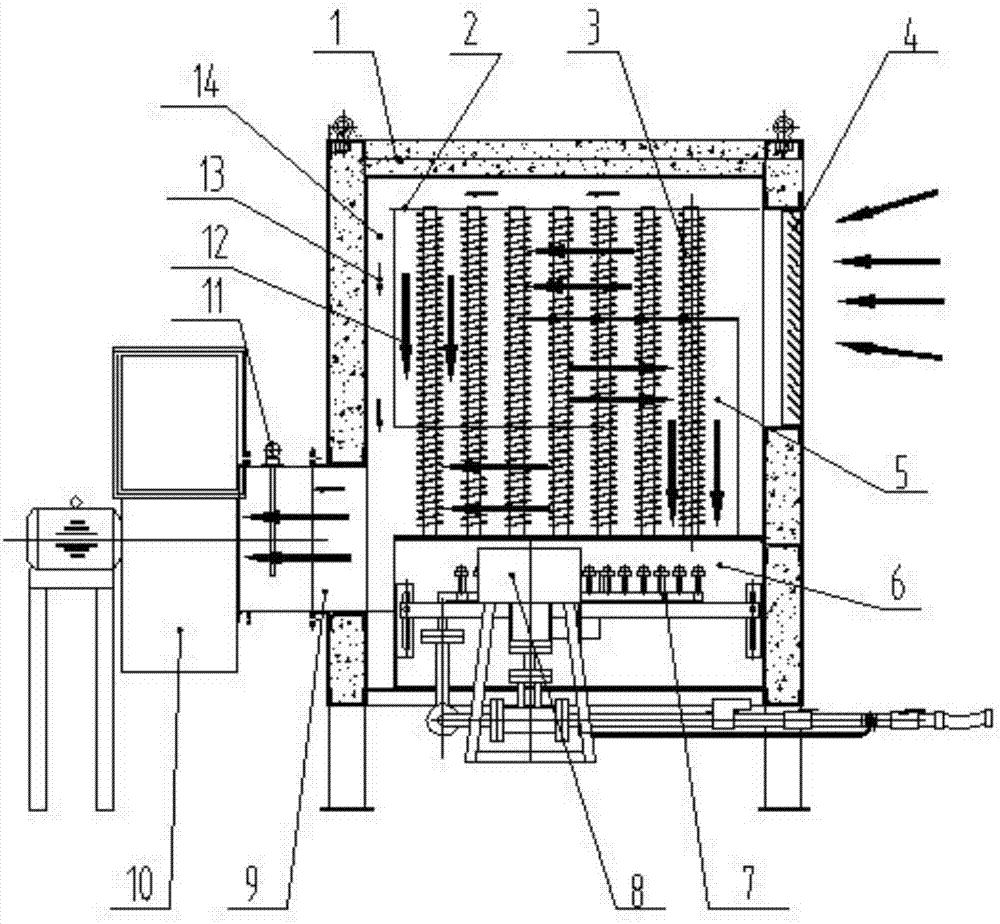

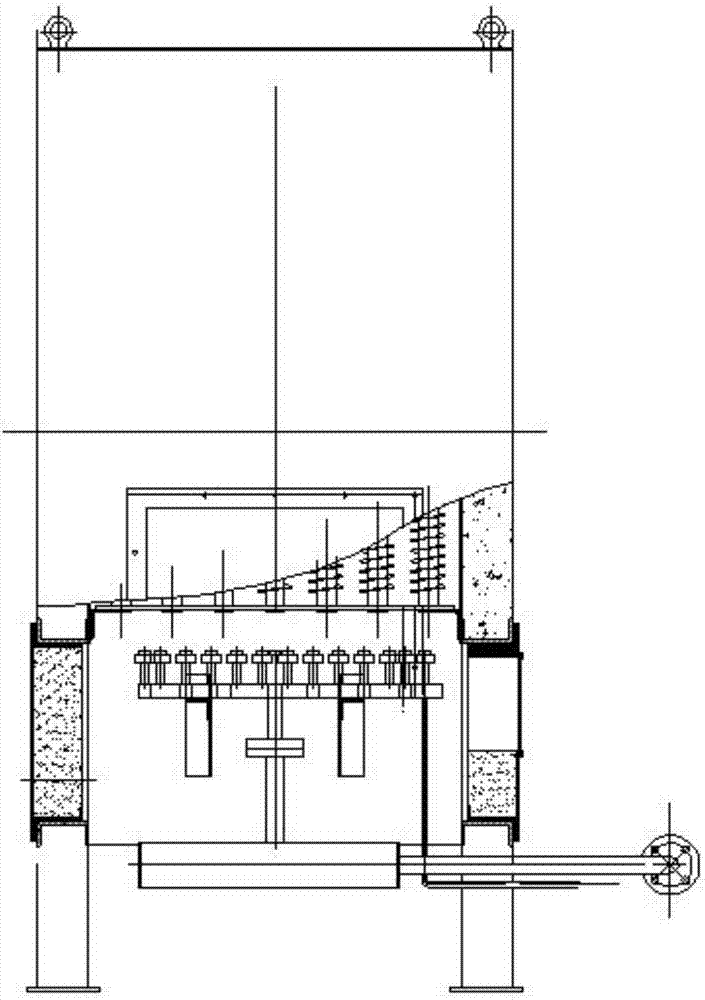

[0012] In order to make the implementation technical means, creative features, objectives and effects of the present invention easy to understand, the present invention will be further elaborated below in conjunction with specific illustrations.

[0013] like figure 1 , figure 2 As shown, a finned tube type gas hot blast stove includes: a hot blast stove body 1, the hot blast stove body 1 is installed on the furnace body bracket, and the hot blast stove body 1 is divided into an upper heat exchange area 5 and a lower part The furnace 6 of the hot blast stove is provided with a cold air inlet of the hot blast stove on one side of the furnace body 1 and a hot air outlet 9 of the hot blast stove on the other side. channel, the S-shaped heat exchange channel is provided with finned tubes 3, the combustion in the furnace 6 generates a large amount of heat, and the heat is transferred to the heat exchange area 5 through the steel plate and finned tubes 3 at the bottom of the heat ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap