Base plate bearing device

A technology for carrying devices and substrates, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor horizontal black lines, breaking, and aggravating friction, so as to reduce the risk of fragmentation and eliminate installation gaps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The features and principles of the present invention will be described in detail below with reference to the accompanying drawings. The examples cited are only used to explain the present invention and are not intended to limit the protection scope of the present invention.

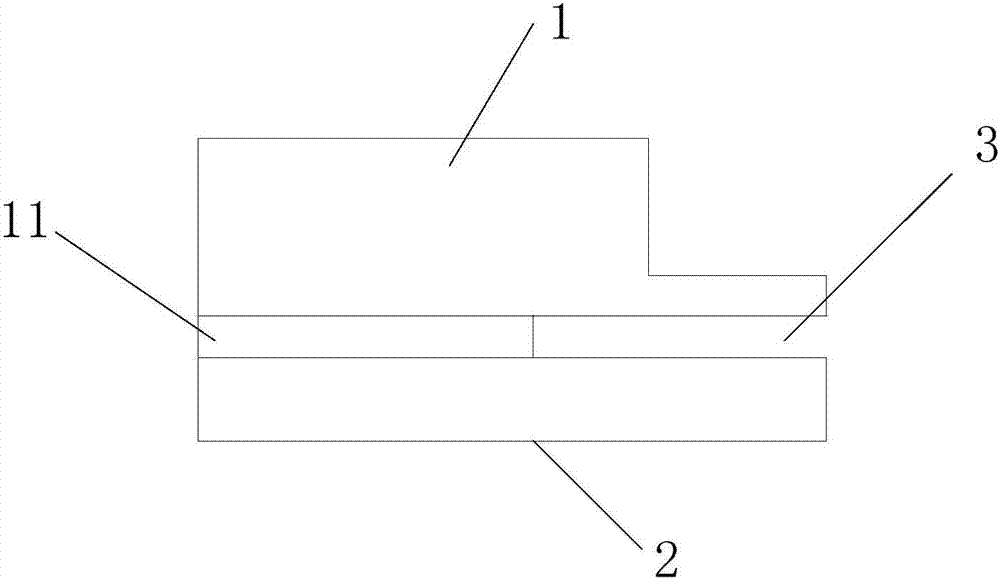

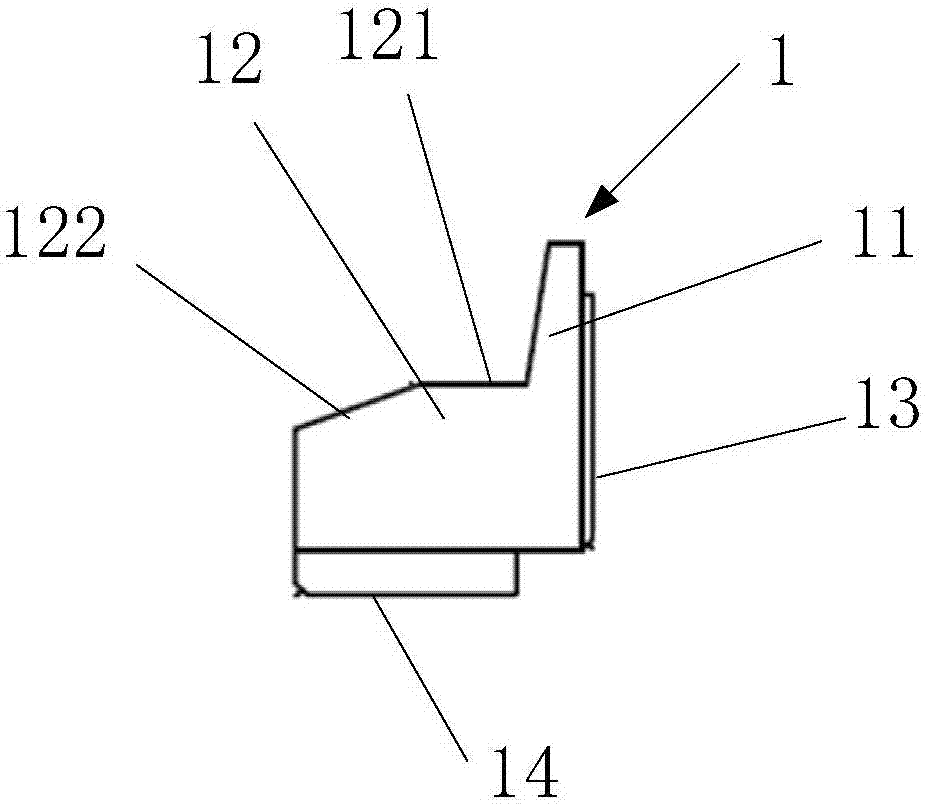

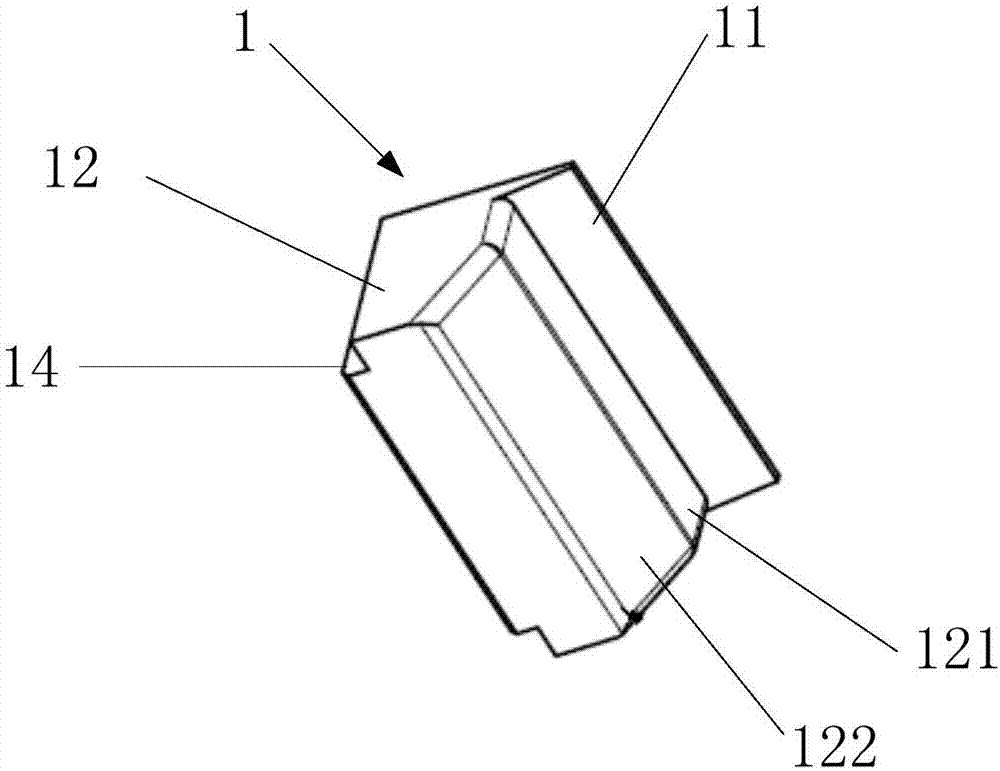

[0027] Such as Figure 2-Figure 8 As shown, this embodiment provides a substrate carrying device, including a carrying frame, a plurality of substrate pressing elements 2 are arranged around the carrying frame, an insulating support 1 is provided on the substrate pressing element 2, and the support 1 It includes a first portion 11 corresponding to the surface of the substrate and a second portion 12 corresponding to the side of the substrate. The substrate pressing element 2 includes a first region 21 corresponding to the surface of the substrate and a second region 22 corresponding to the side of the substrate. The first part 11 is embedded in the first area 21 and the second part 12 is fixedly conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com