Sealing structure, dish washing machine inner tank and dish washing machine

A technology of dishwasher liner and sealing structure, which is applied in the direction of tableware washing machine/rinsing machine, tableware washing machine/rinsing and rinsing machine parts, engine sealing, etc., which can solve the deformation of the inner tank top plate and increase the complexity of operations , The sealing strip cannot completely seal the water and other problems, so as to achieve the effect of strengthening the sealing effect and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

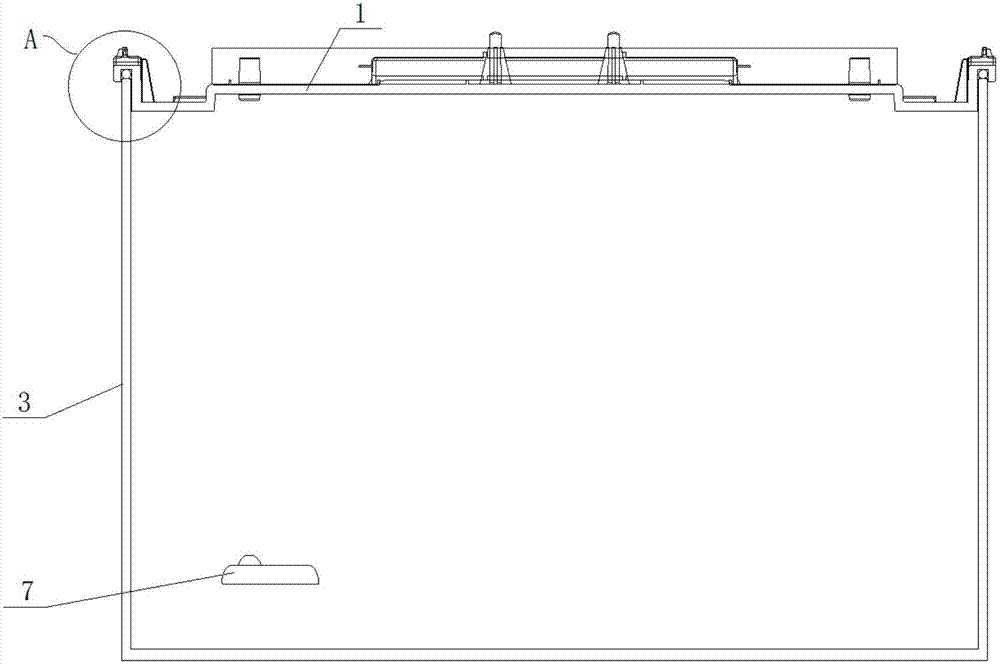

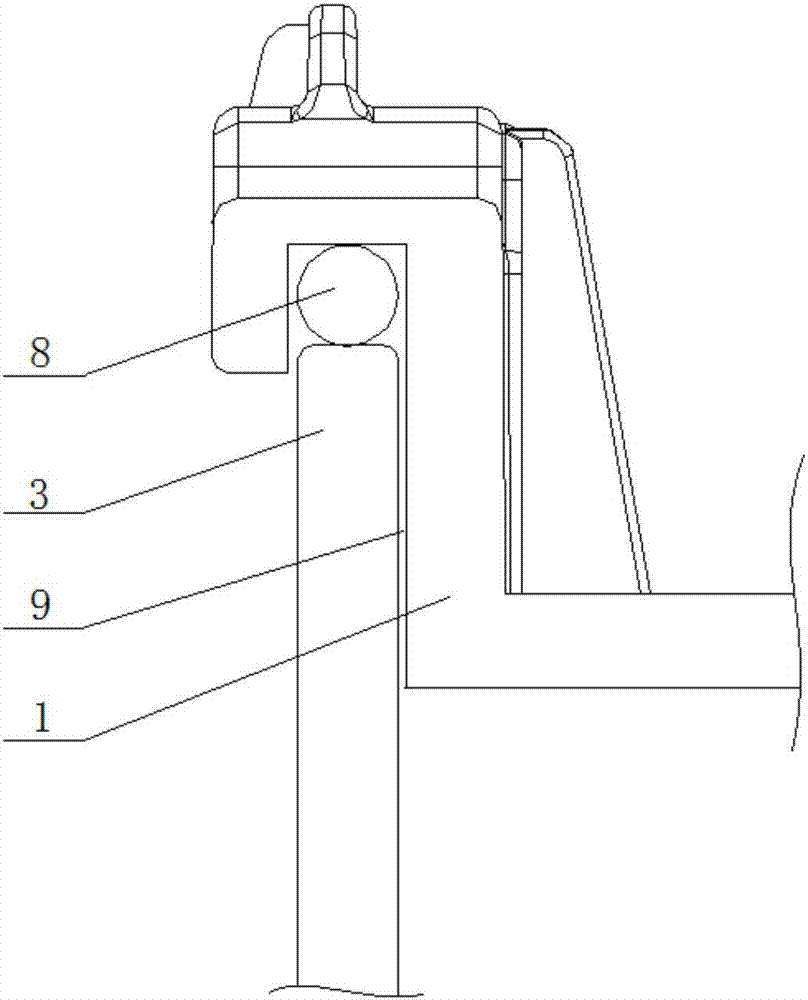

[0030] refer to figure 1 and figure 2 , in the prior art, the dishwasher includes a dishwasher inner tank and a shower 7 arranged in the dishwasher inner tank. The dishwasher liner includes an inner container bottom plate, an inner container middle plate 3 and an inner container top plate 1, and a sealing ring 8 is arranged between the top of the inner container middle plate 3 and the inner container top plate 1. Usually, the inner container below the sealing ring 8 There will be a certain gap at the junction 9 between the inner tank middle board 3 and the inner tank top board 1 . The water flow direction sprayed by shower 7 is in figure 1 As shown in , the water flow injected in this direction may directly impact on the vicinity of the joint position of the inner tank middle plate 3 and the inner tank top plate 1, specifically refer to figure 2 , when the water flow hits the joint 9 of the inner tank middle plate 3 and the inner tank top plate 1 and its vicinity, due to ...

Embodiment 2

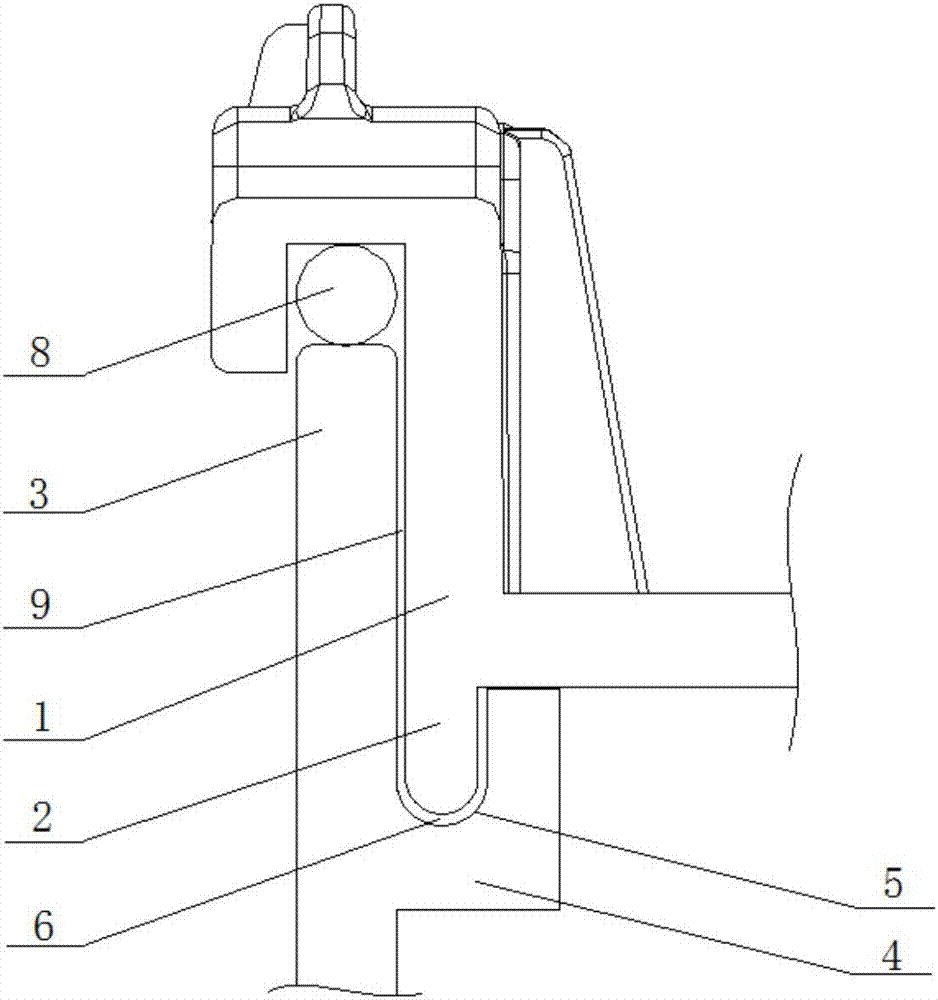

[0043] refer to Figure 4 , in this embodiment, the only difference from the first embodiment above is that the rib 2 is spaced from one end of the bottom surface of the inner tank top plate 1, and the groove 5 in the sealing member 4 surrounds the sealing groove 6 of the rib 2 alone .

[0044] Such as Figure 4 As shown, the cross-sectional shape of the rib 2 is U-shaped, and the groove 5 in the sealing member 4 is a U-shaped groove, which surrounds the rib 2 alone. Thus, the top surface of the sealing member 4 and the bottom surface of the inner tank top plate 1 will fit together at the position between the rib 2 and the inner tank middle plate 3, which is equivalent to the downstream of the sealing structure composed of the rib 2 and the sealing member 4. A secondary seal is formed, Figure 4 It can be clearly seen that a horizontal sealing surface 10 is formed, which strengthens the sealing effect.

[0045] In summary, in this embodiment, the sealing member 4 and the r...

Embodiment 3

[0047] In this embodiment, a dishwasher liner is provided, which includes a liner middle plate 3, a liner top plate 1, and the middle plate for the dishwasher liner of Embodiment 1 or Embodiment 2. 3 Sealing structure with the top plate of the inner tank.

[0048] In the dishwasher liner, there is no hidden danger of water leakage at the joint 9 between the top of the liner middle plate 3 and the liner top plate 1 . At the same time, the installation of the sealing structure in the dishwasher liner only needs to be plugged in. Compared with the application of sealant in the prior art, it has the advantage of easy installation, which in turn improves the assembly of the dishwasher liner. speed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com