Sand box with convenience in taking sand lump

A technology for sand boxes and sand blocks, which is applied in the field of sand boxes that can facilitate the extraction of sand blocks, can solve the problems of single size, high friction, and high price in the production of sand molds, and achieve the goal of improving processing efficiency, improving efficiency, and improving use efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

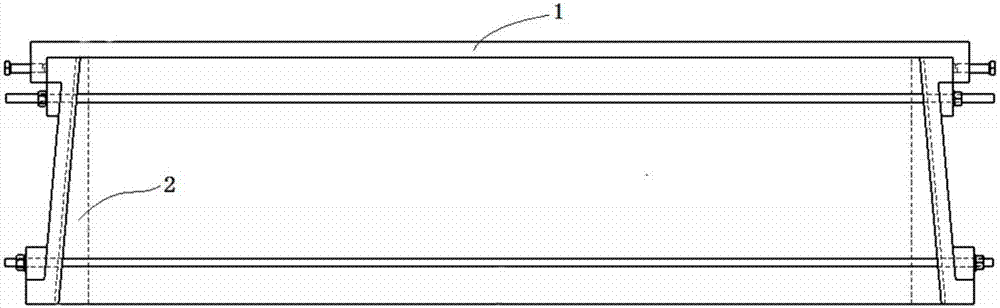

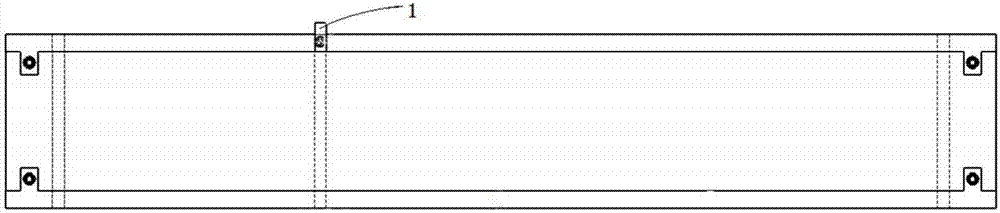

[0012] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, the sand box of the present invention is in the shape of an isosceles trapezoid, which is composed of front, rear and both sides sand box plates, the two sides sand box plates are two waists of an isosceles trapezoid, and the sand box plates are wooden boards. The included angles between the sand box plates on both sides and the vertical plane are 4-7°, preferably 5-6°. The inner sides of the sand box plates on both sides are respectively provided with wedge blocks 2 that fit the sand box plates. The side of tight block 2 and the inner sides of both sides of the sand box boards are inclined planes, and the other side is a vertical plane. Setting the included angle between the sand box plates on both sides and the vertical plane to 4-7° and using the wedge block 2 at the same time can reduce the fric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com