Filling mechanism

A filling and rotating mechanism technology, used in packaging, bottle filling, liquid bottling, etc., can solve the problems of reducing work efficiency, manual operation errors, and high production costs, reducing labor intensity of workers, improving work efficiency, and mechanical efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

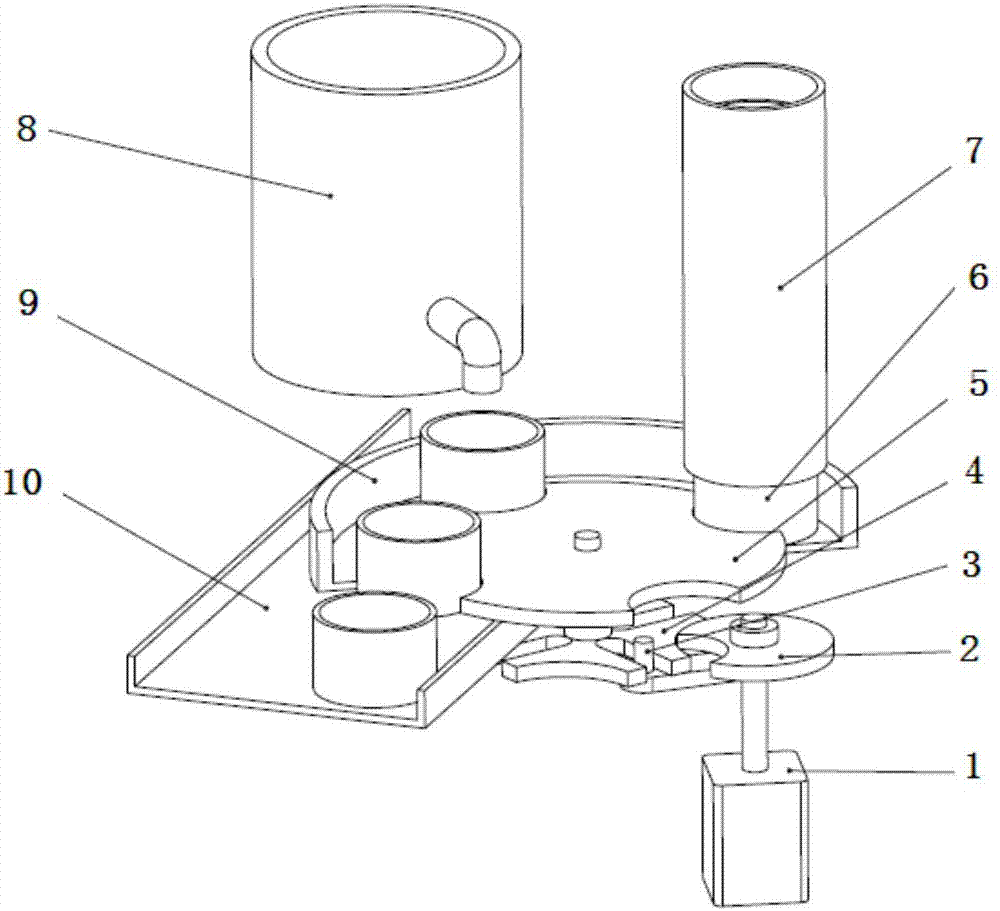

[0017] Examples, see attached figure 1 , a filling mechanism, including a rotary mechanism 1 and an assembly line mechanism 10, the rotary mechanism includes a rotary motor and a rotary shaft connected to the output shaft of the rotary motor, the rotary motor is mounted on a frame through a motor fixing plate.

[0018] The rotating shaft of the rotating mechanism is equipped with a sheave mechanism; the sheave mechanism is a single-arm external meshing sheave mechanism, and the sheave mechanism includes a notch disc 2, a rotating arm with a cylindrical pin 3 and four radial The sheave 4 of the groove, the rotating shaft of the rotating mechanism is equipped with a notch disc, the lower part of the notch disc is fixedly connected to the rotating arm, and the cylindrical pin on the rotating arm can enter and exit the radial groove, thereby stirring the sheave to rotate and stop, and the notch The circumference of the disc matches the concave circumference of the sheave.

[0019...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com