Galvanizing device for electrode wire core material for precision mold cutting

A technology of precision mold and electrode wire, applied in the field of galvanizing process and production equipment for electrode wire core material, can solve the problems of uneven galvanizing, unfavorable collection, easy thermal deformation of core material, etc. The effect of uniform zinc and material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

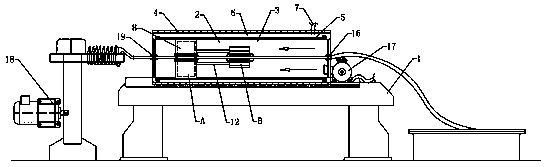

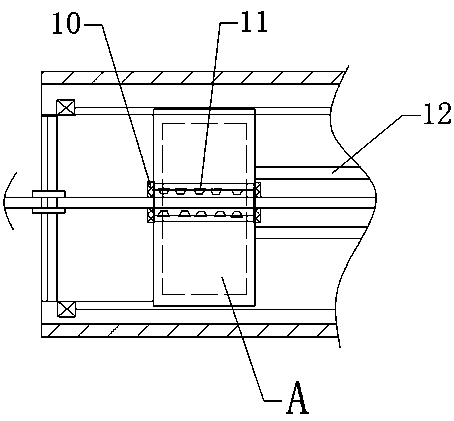

[0026] The embodiment is basically as attached figure 1 , figure 2 Shown: the galvanizing device for the electrode wire core material for precision mold cutting, including a frame 1 and a galvanizing mechanism 2 arranged on the frame, and the galvanizing mechanism 2 includes a cabinet 3 arranged on the frame 1, and The horizontal pipe 4 in the cabinet 3 is provided with guide grooves 5 on the upper and lower pipe walls of the horizontal pipe 4, and the inner sides of the upper and lower pipe walls of the horizontal pipe 4 are provided with cavities communicating with the guide grooves 5 6. The horizontal pipeline 4 is provided with a liquid zinc guide pipe 7 connected to the cavity 6, and a vertical pole 8 is slidably connected to the guide groove 5, and the pole 8 is provided with a cavity on the inner side of the pipe wall. 6 connected inner cavities, and the middle part of the column rod 8 is provided with a round hole 10 to accommodate the passage of the electrode wire c...

Embodiment 2

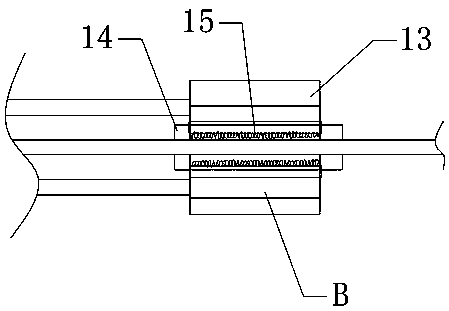

[0031] Such as Figure 5 As shown, the structure and principle of this embodiment are basically the same as those of Embodiment 1, the difference being that: the left and right ends of the pole 8 are provided with guide strips 20, and the guide strips 20 can cover the upper and lower sides of the horizontal pipe 4. The guide groove 5 on the lower pipe wall, the guide strips 20 at both ends of the mast 8 all stretch out from the outsides of the both side baffle plates of the horizontal pipe 4, and the guide groove 5 can be shielded by setting the left and right ends of the mast 8. Bar 20, to ensure that during the process of moving the galvanized pole 8, too much zinc liquid will not overflow in the guide groove 5, saving materials, and when the pole 8 moves from one end to the other, it will protrude from the horizontal through sliding The guide bar 20 on the outside of the baffle plate at both ends of the pipeline 4 can reset the mast 8 and the support 12 connected thereto, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com