Galvanized steel wire surface treatment method and device

A surface treatment device and technology of galvanized steel wire, applied in hot dip plating process, coating, metal material coating process, etc., can solve the problems of unevenness, affect product quality, low efficiency, etc., achieve uniform galvanization, convenient The effect of promotion and operation is simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

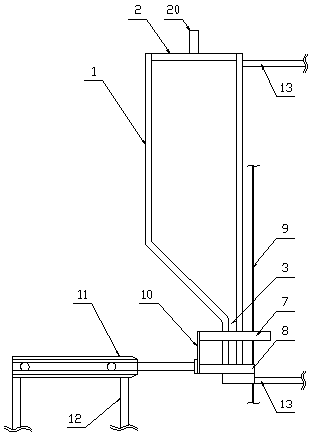

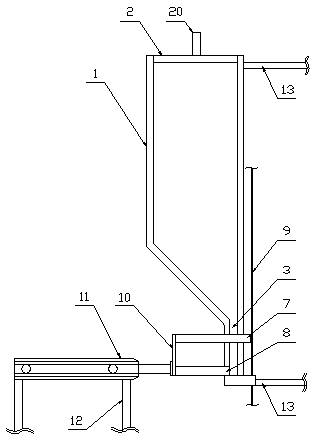

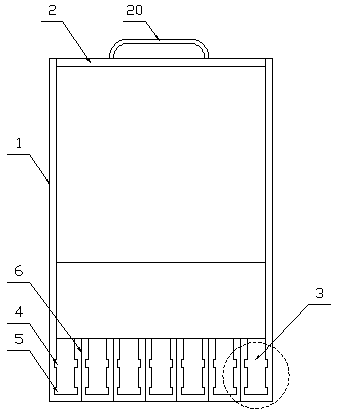

[0032] Such as Figure 1 to Figure 7 As shown, the present invention includes a hopper 1, and the hopper 1 is fixed on the chimney of exhaust gas treatment through a connecting mechanism 13. In order to facilitate adjustment of the distance with the steel wire 9, the connecting mechanism 13 of the present invention is a telescopic structure and specifically includes a connecting rod 17 and Connecting pipe 18, one end of connecting rod 17 and the other end welded by the hopper are movably inserted into one end of connecting pipe 18, and the other end of connecting pipe is welded on the chimney. In order to fix the position between connecting rod and connecting pipe, the connection of the present invention The pipe 18 is provided with a screw hole (the screw hole is not marked, and coincides with the bolt), and a matching bolt 19 is arranged in the screw hole, and the connecting rod can be tightened and loosened by the rotation of the bolt; in order to facilitate feeding, the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com