Valve trains for internal combustion engines

A valve train, internal combustion engine technology, applied in the direction of machine/engine, mechanical equipment, engine components, etc., can solve problems such as disadvantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

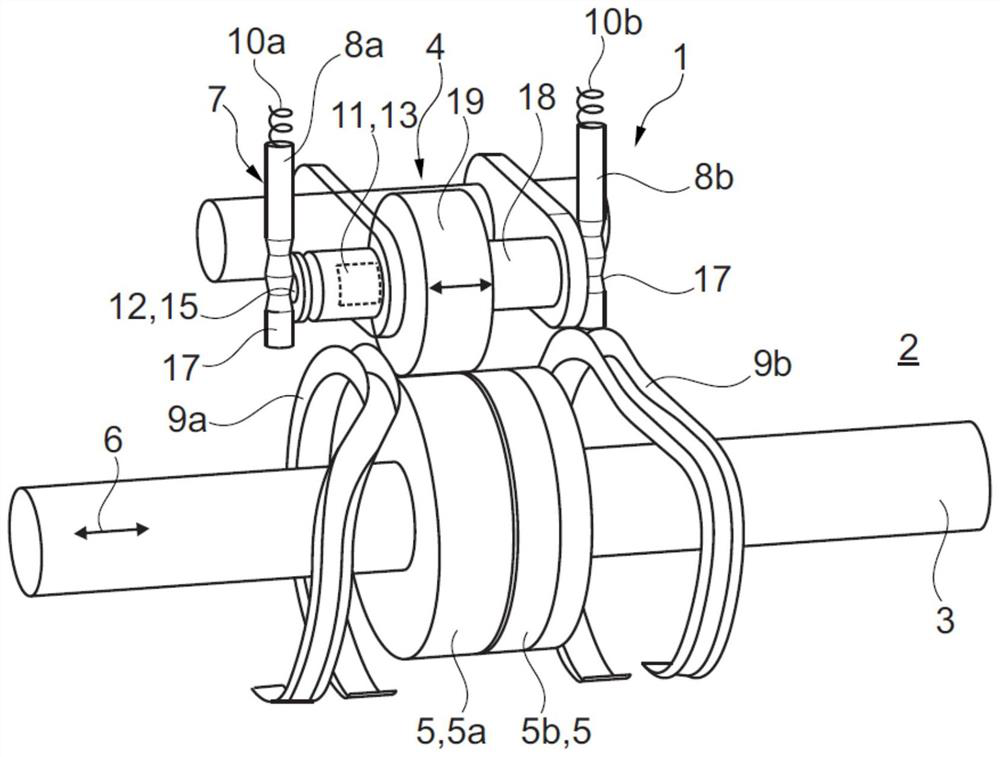

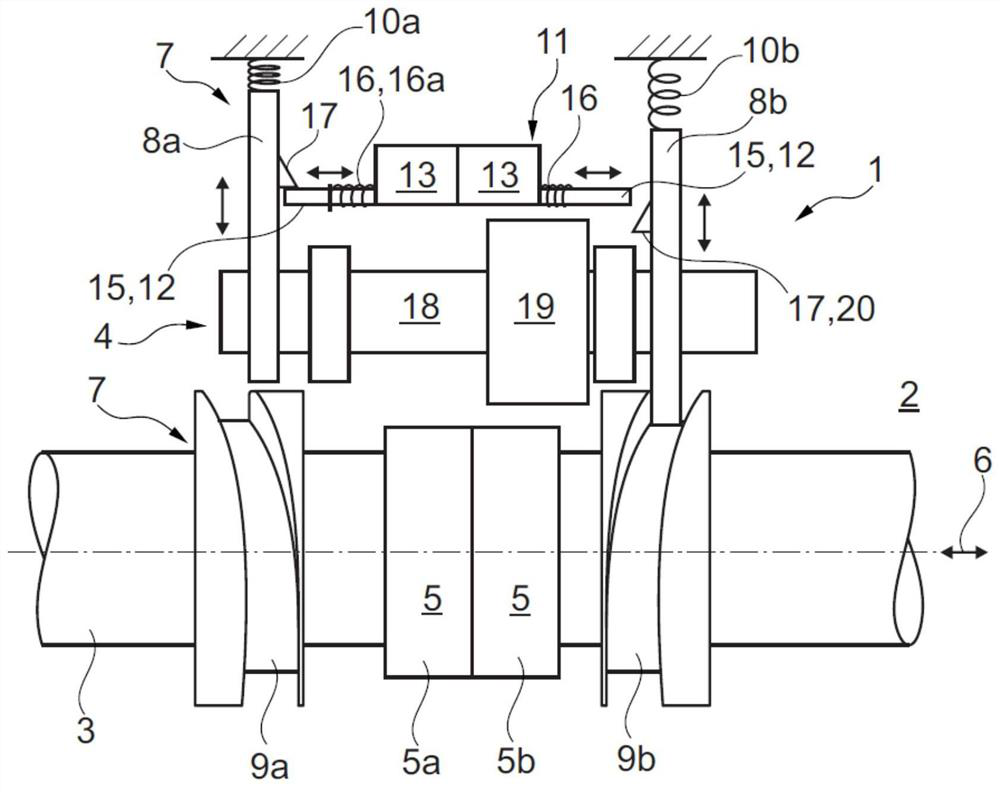

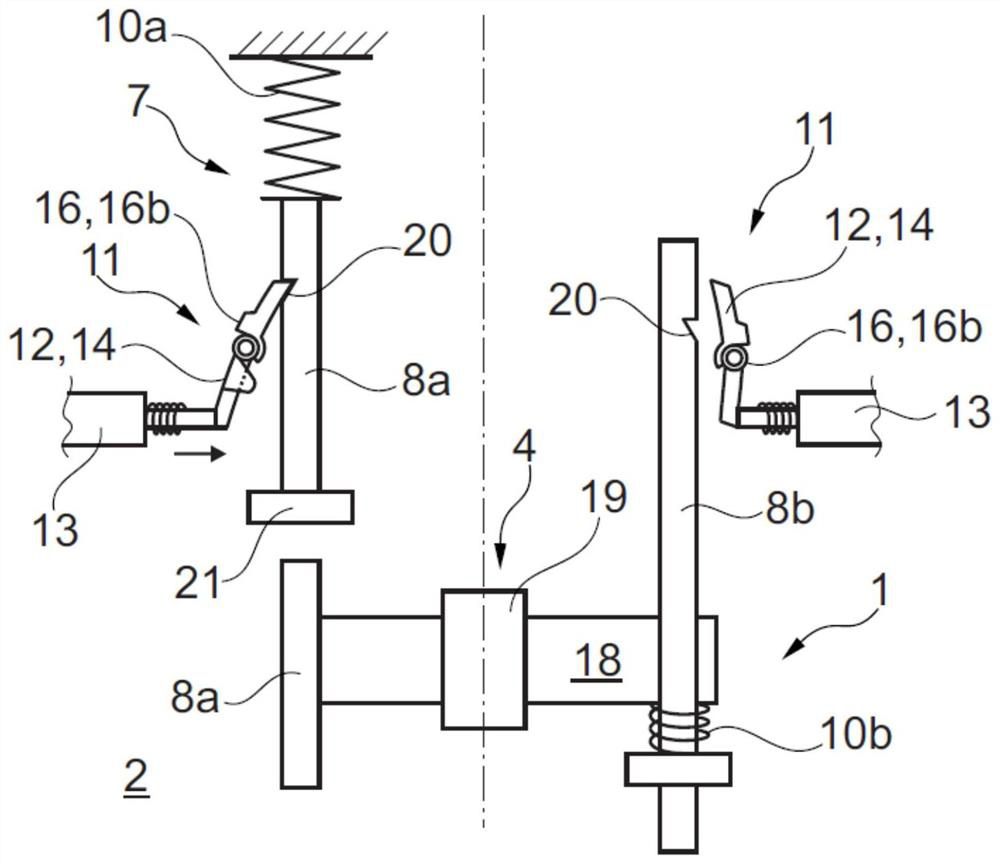

[0021] according to figure 1 and figure 2 , the valve train 1 according to the invention for an internal combustion engine 2 which is only indicated has a camshaft 3 and a cam follower 4 . A first cam 5 a and an axially adjacent second cam 5 b are arranged in a torque-resistant manner on the camshaft 3 here, said cams having different cam profiles. For example, one of the two cams 5a, 5b can have only a base circle and thus no cam lobe, so that separation via its cylinder is possible. In order to be able to change between the cam profiles of the two cams 5a, 5b, the cam follower 4 is axially adjustable, ie with respect to the axial direction of the camshaft 3 and ie between a first position and a second position , in the first position, it is drivenly or respectively operatively connected with the cam 5a (see figure 1 ), in said second position, it is drivenly or respectively operatively connected with the second cam 5b (see figure 2 ). An adjusting device 7 is also pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com