Independent integrated hydraulic linear driving system

A linear drive, integrated technology, applied in the direction of fluid pressure actuation device, servo motor, actuator accumulator, etc., can solve problems such as reducing the reliability of hydraulic system, inconvenient maintenance of hydraulic pipeline, and decreasing the cleanliness of hydraulic oil. , to achieve the effect of less heat generation, shortened design and manufacturing cycle, and improved possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

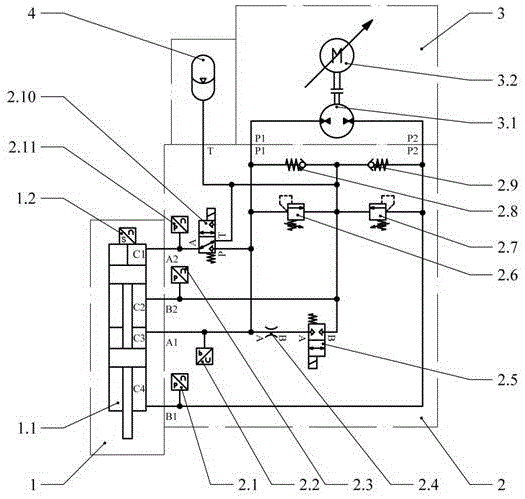

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

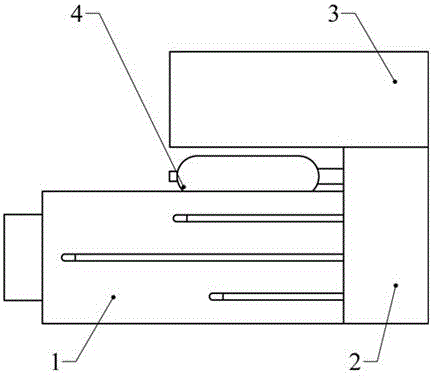

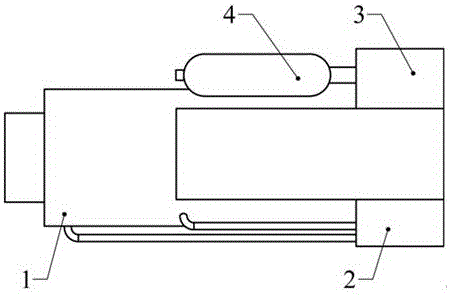

[0024] see figure 1 , the present invention mainly includes: a hydraulic cylinder module 1, a hydraulic control integrated module 2, a motor pump module 3, an accumulator module 4, the C1 cavity of the hydraulic cylinder module 1 communicates with the A2 port of the hydraulic control integrated module 2, and the hydraulic cylinder The C2 cavity of module 1 is connected with the B2 port of the hydraulic control integrated module 2, the C3 cavity of the hydraulic cylinder module 1 is connected with the A1 port of the hydraulic control integrated module 2, and the C4 cavity of the hydraulic cylinder module 1 is connected with the hydraulic control integrated module 2 The P1 port of the motor pump unit module 3 is connected to the P1 port of the hydraulic control integrated module 2, the P2 port of the motor pump unit module 3 is connected to the P2 port of the hydraulic c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com