Iron tower support material processing method

A processing method and auxiliary material technology, applied in the direction of electrical digital data processing, special data processing applications, instruments, etc., can solve the problems of complex operation, improper parameters, lack of versatility, etc., and achieve the effect of simple operation and low complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

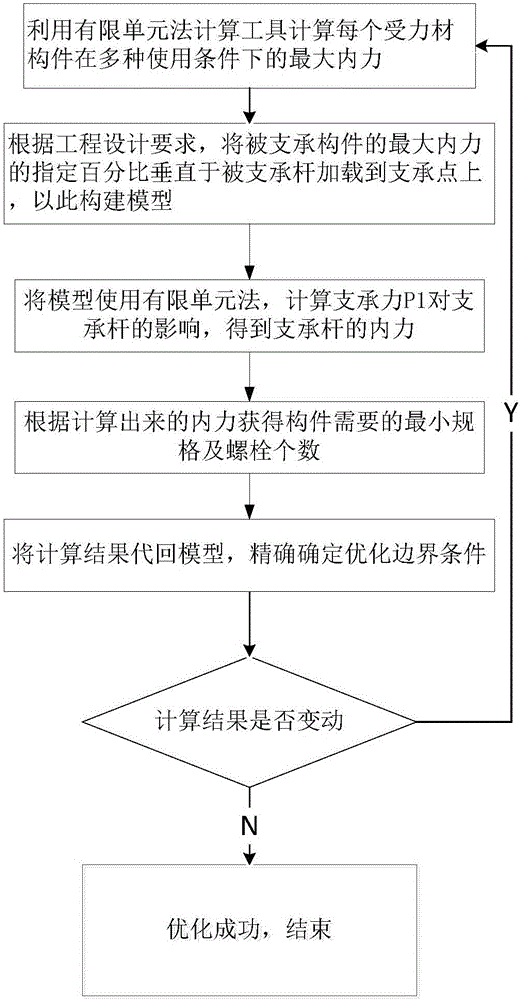

[0020] Such as figure 1 Shown, the processing method of this iron tower auxiliary material, it may further comprise the steps:

[0021] (1) Use the finite element method calculation tool to calculate the maximum internal force of each stressed member under various service conditions;

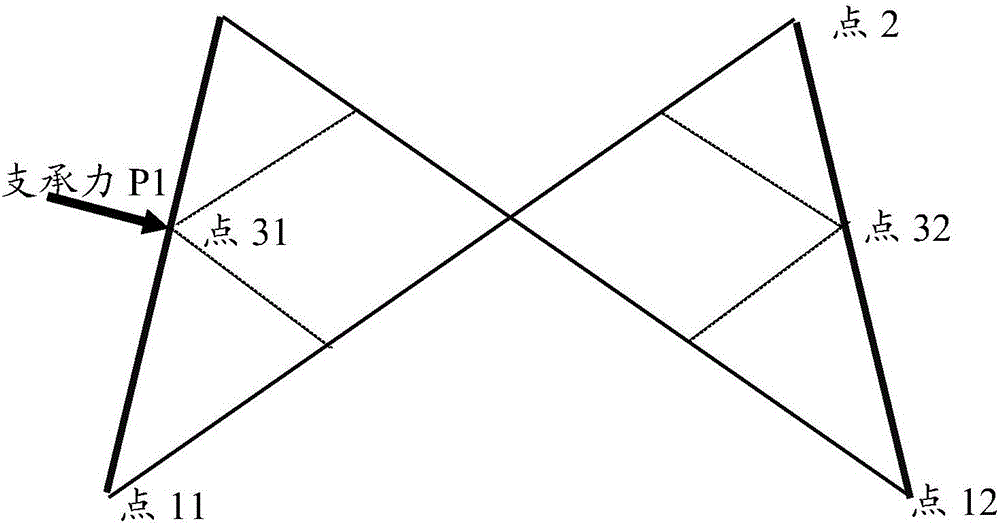

[0022] (2) According to the engineering design requirements, the specified percentage of the maximum internal force of the supported member is loaded on the supporting point perpendicular to the supported rod to construct the model;

[0023] (3) Using the finite element method to calculate the influence of the support force P1 on the support rod to obtain the internal force of the support rod;

[0024] (4) Obtain the minimum specification and number of bolts required by the component according to the calculated internal force;

[0025] (5) Substitute the calculation results back into the model to accurately determine the optimal boundary conditions;

[0026] (6) Determine whether the calculat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com