A wire deicing system for high-voltage power transmission and transformation projects

A technology for power transmission and transformation and transmission lines, which is applied in the field of wire deicing systems for high-voltage power transmission and transformation projects, which can solve problems such as inconvenient use, and achieve the effects of energy saving, good strength and frequency, and appropriate distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

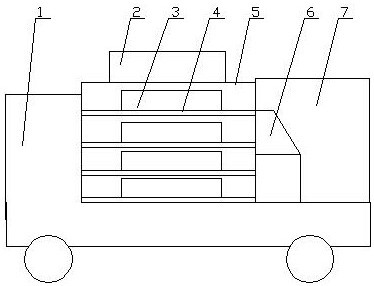

[0047] Embodiment one, such as figure 1 As shown, the present invention provides a wire deicing system for high-voltage power transmission and transformation engineering, including a carrier vehicle 1, a compartment 5 is arranged at the rear of the carrier vehicle 1, a shelf 4 is arranged in the compartment 5, and a shelf 4 is arranged inside the shelf 4. Several self-propelled de-icing devices 3 are set, a control room 7 is set at the rear of the compartment 5, a console 6 is arranged in the control room 7, an unmanned aerial vehicle 2 is arranged on the top of the compartment 5, and the unmanned aerial vehicle 2 The lower part is provided with a fixing mechanism corresponding to the self-propelled de-icing device 3, and the console 6 is connected with the signal of the drone 2 and the self-propelled de-icing device 3, and the self-propelled de-icing device 3 includes a walking mechanism , a deicing mechanism is set on the walking mechanism.

[0048] The bottom plate 21 is p...

Embodiment 2

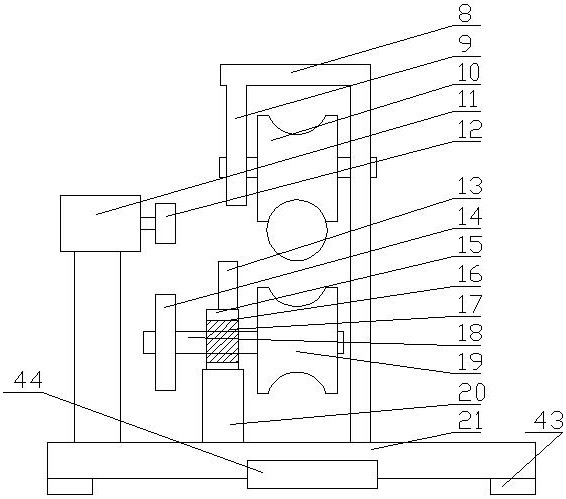

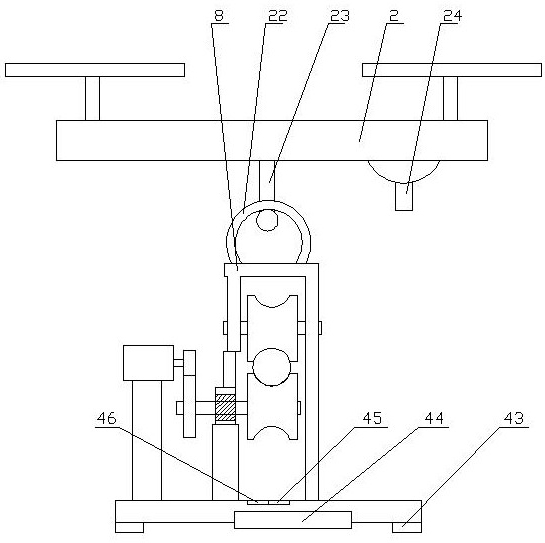

[0053] Such as figure 2 and image 3 As shown, the difference between this embodiment and Embodiment 1 is:

[0054] Described walking mechanism comprises base plate 21, and the top of described base plate 21 two ends is provided with L-shaped support 8, and the top of described L-shaped support 8 is provided with mounting rod 9 downwards, and described mounting rod 9 and described L-shaped support 8 are provided with Pulley 10, telescoping mechanism 20 is set on described base plate 21 below described installation bar 9, and the upper end of described telescoping mechanism 20 is provided with installation block 15, and vertical stop bar 13 is set on described installation block 15, and described installation A mounting hole 16 is arranged in the middle of the block 15, and a rotating shaft 18 parallel to the central axis of the pulley 10 is set through a bearing 17 in the mounting hole 16, and a driving wheel 19 matched with the pulley 10 is arranged on the rotating shaft 18...

Embodiment 3

[0061] Such as Figure 4 to Figure 7 As shown, the difference between this embodiment and Embodiment 1 is:

[0062] The deicing mechanism includes an icicle removal mechanism and an ice film removal mechanism. The icicle removal mechanism includes a column 28 provided at the front end of the base plate 21, a launch tube 25 is provided at the upper end of the column 28, and a launch tube 25 is provided at the end of the launch tube 25. Compression spring 30, the front end of the compression spring 30 is connected with a push rod 26, the launching tube 25 is provided with a fixing groove 27, the push rod 26 is provided with a slider 29 passing through the fixing groove 27, and the slider 29 When contacting with the front end of the fixing groove 27, the ejector stick 26 stretches out from the launch tube 25, and a second drive mechanism is set on the bottom plate corresponding to the slider 29, and the second drive mechanism includes a set on the bottom plate 21. The driving mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com