Ball joint assembly with rotation sensor assembly

A technology of rotating sensor and rotating device, applied in the field of joint group, can solve the problem of not allowing to evaluate and detect the rotation and rotation angle of joint axis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

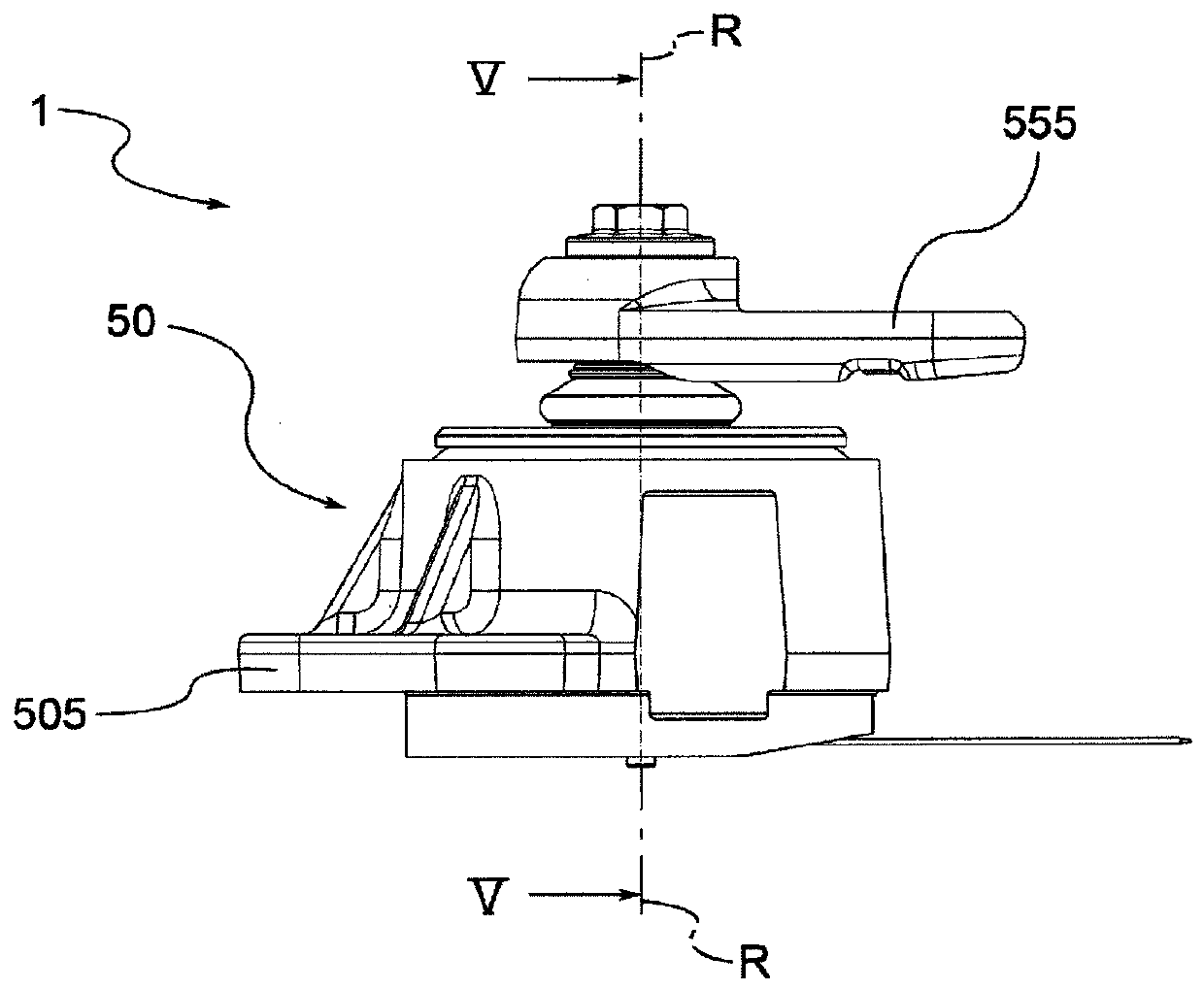

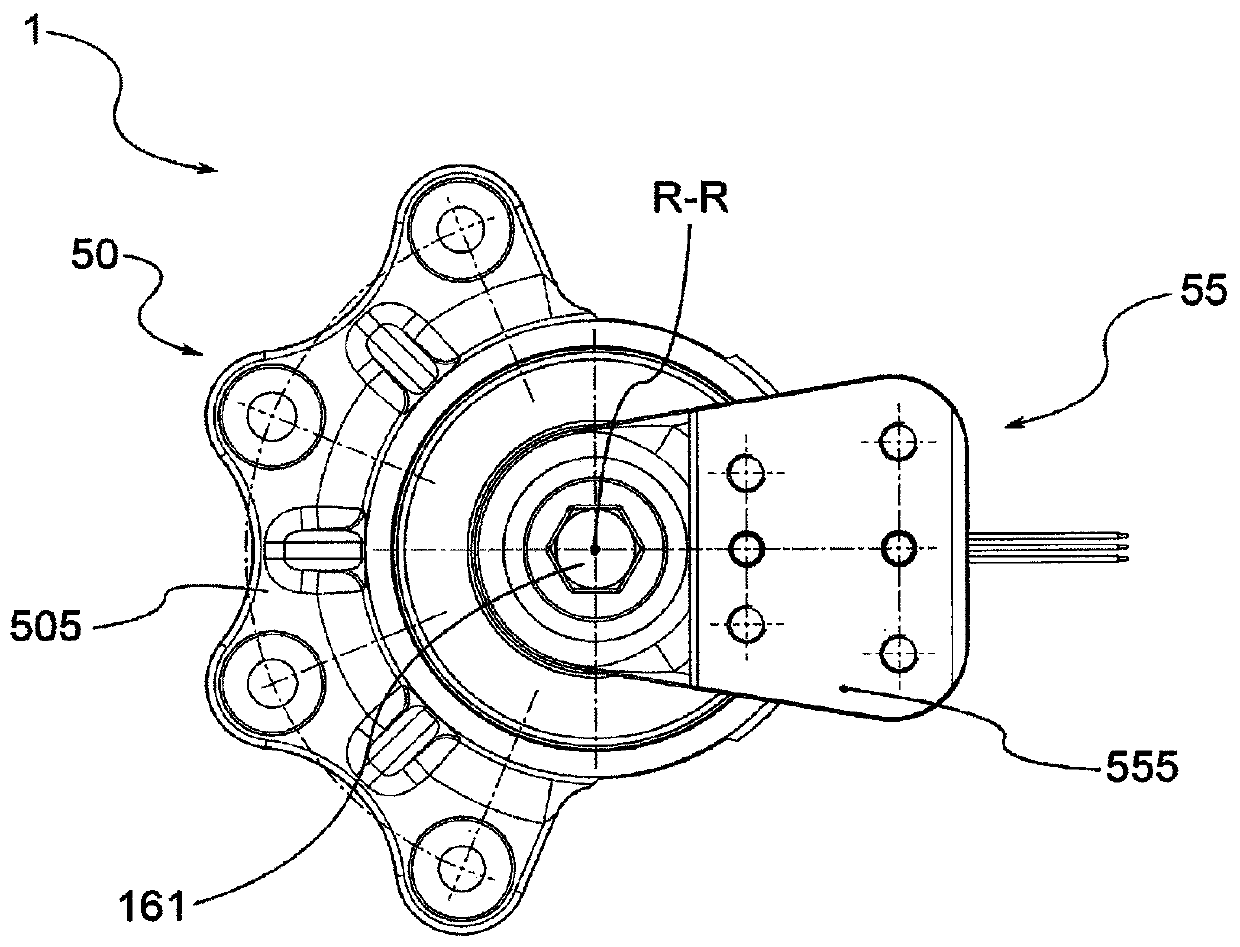

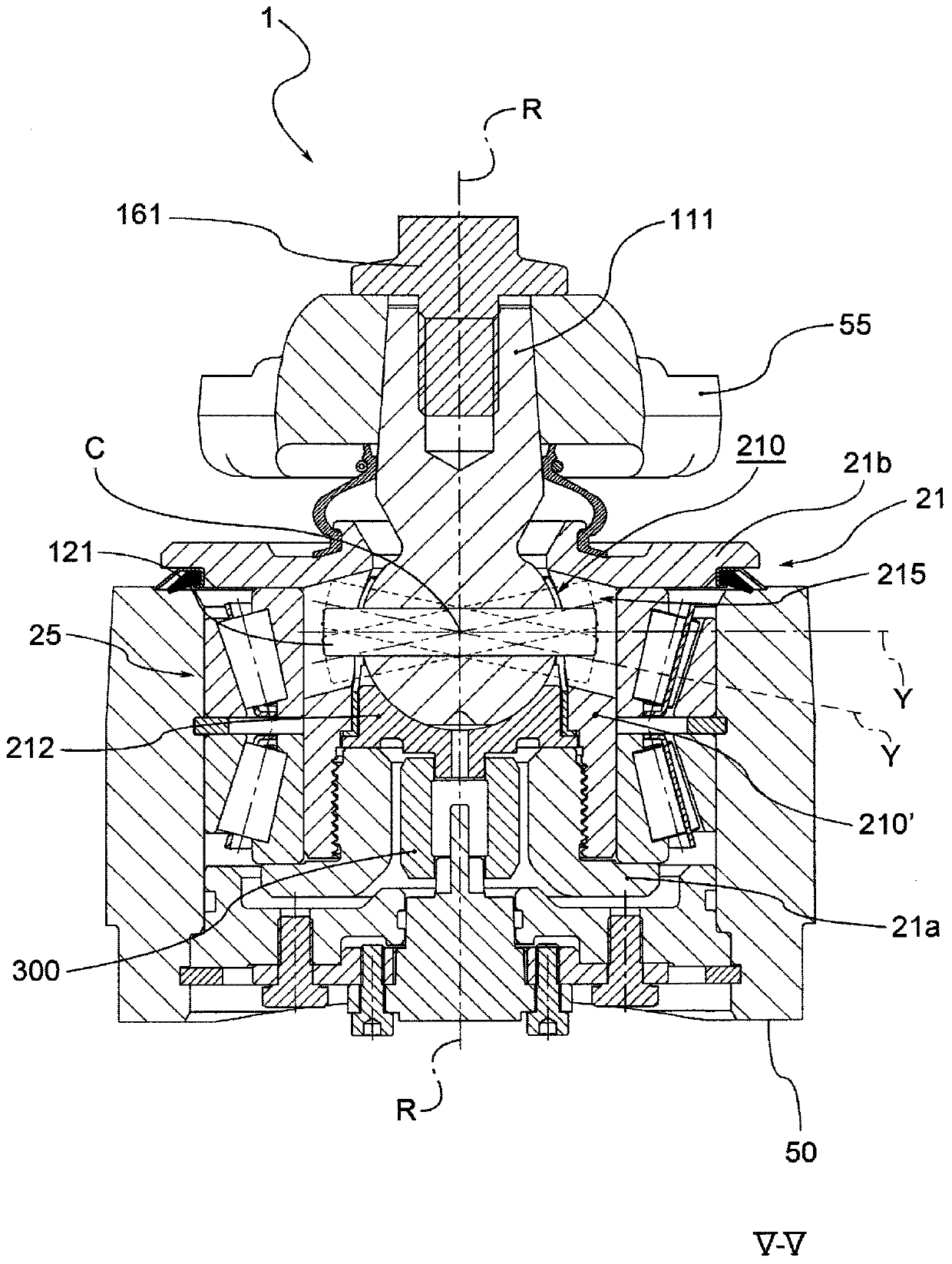

[0013] With reference to the accompanying drawings, the reference numeral 1 generally designates a joint set as a whole according to a preferred embodiment.

[0014] Preferably, the joint set is adapted to operatively connect the first part and the second part. In particular, the joint group 1 is adapted to allow a movement of a first part relative to a second part, wherein said movement is of the rotary type, preferably around the axis of rotation R-R. Thus, by means of the joint set 1 the first part is adapted to rotate relative to the second part and / or vice versa.

[0015] It should be noted that the invention is not limited to the type of components connected to and from the joint set 1 . Any component to which the joint set 1 is attachable is adapted to be operatively connected to another component by the knot set, according to the description given below. For example, in one embodiment the joint set 1 is operatively connected to the jack and the shaft in such a way th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com