Iron core lamination platform of rolled iron core transformer

A technology of transformer iron core and lamination table, which is applied in the field of transformer manufacturing, can solve the problems of increasing the difficulty of winding winding and reducing the ability of short circuit, etc., and achieves the effect of simple structure, changing working state, and high lamination precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

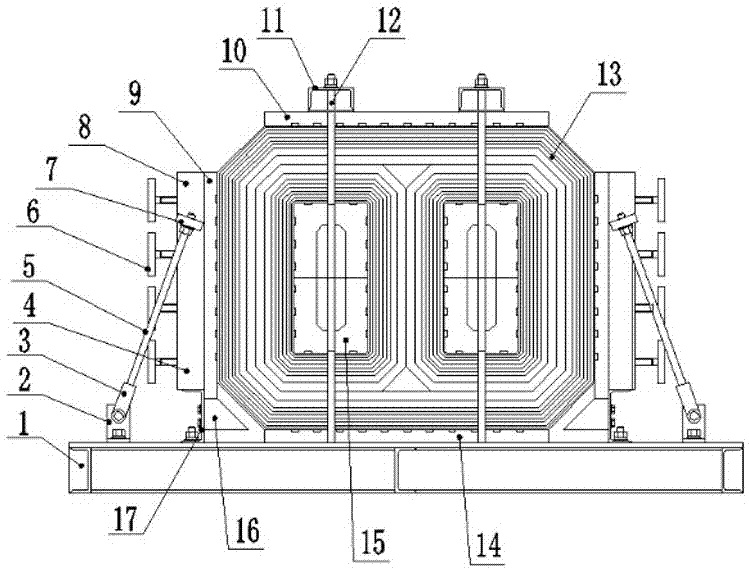

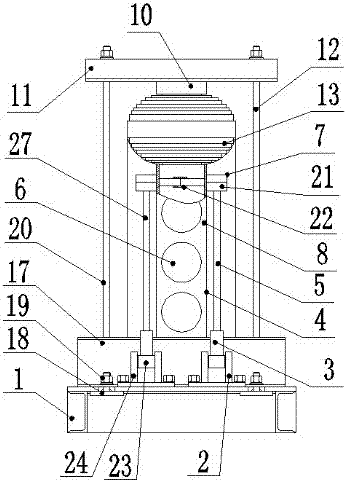

[0017] Such as figure 1 and figure 2 As shown, the winding core transformer core lamination platform includes a base 1, the upper surface of the base 1 is provided with a lower backing plate 14, and a plurality of front screw rods located on the front side of the lower backing plate are installed on the base 1 12 and the rear screw rod 20 located at the rear side of the lower backing plate, the corresponding front screw rod 12 and the rear screw rod 20 are equipped with a top pressure plate 11 at the end far away from the base 1, and a plurality of the top pressure plates 11 A backing board 10 is installed on the lower surface of the lower backing board 14 at a position corresponding to the lower backing board 14, and a topping device is respectively provided on the left side and the right side of the lower backing board 14 on the base 1.

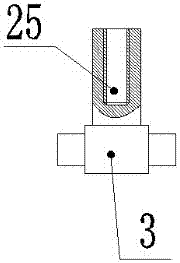

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the tightening device includes a first bracket 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com