Use of a fiber composite material to produce a shift fork and corresponding shift fork

A technology of fiber composite materials and shift forks, which can be used in mechanical control devices, transmission control, components with teeth, etc., and can solve problems such as high cost and high weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

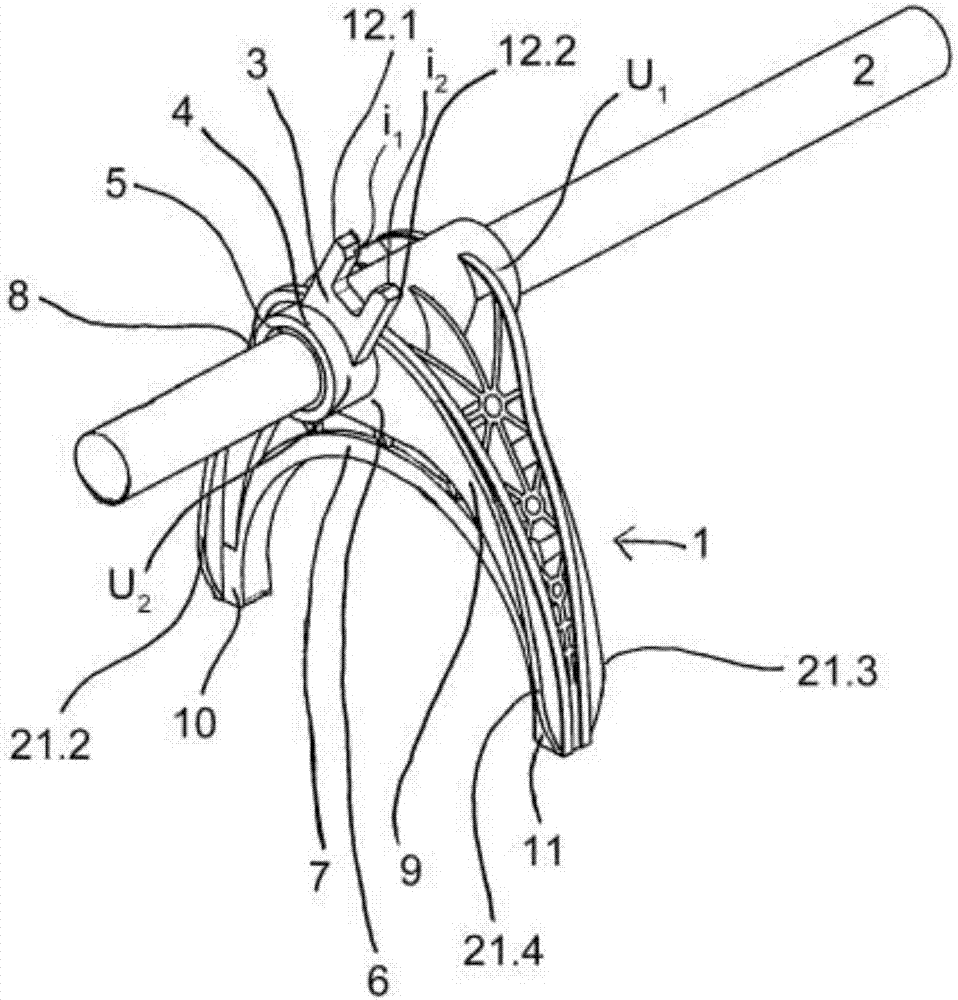

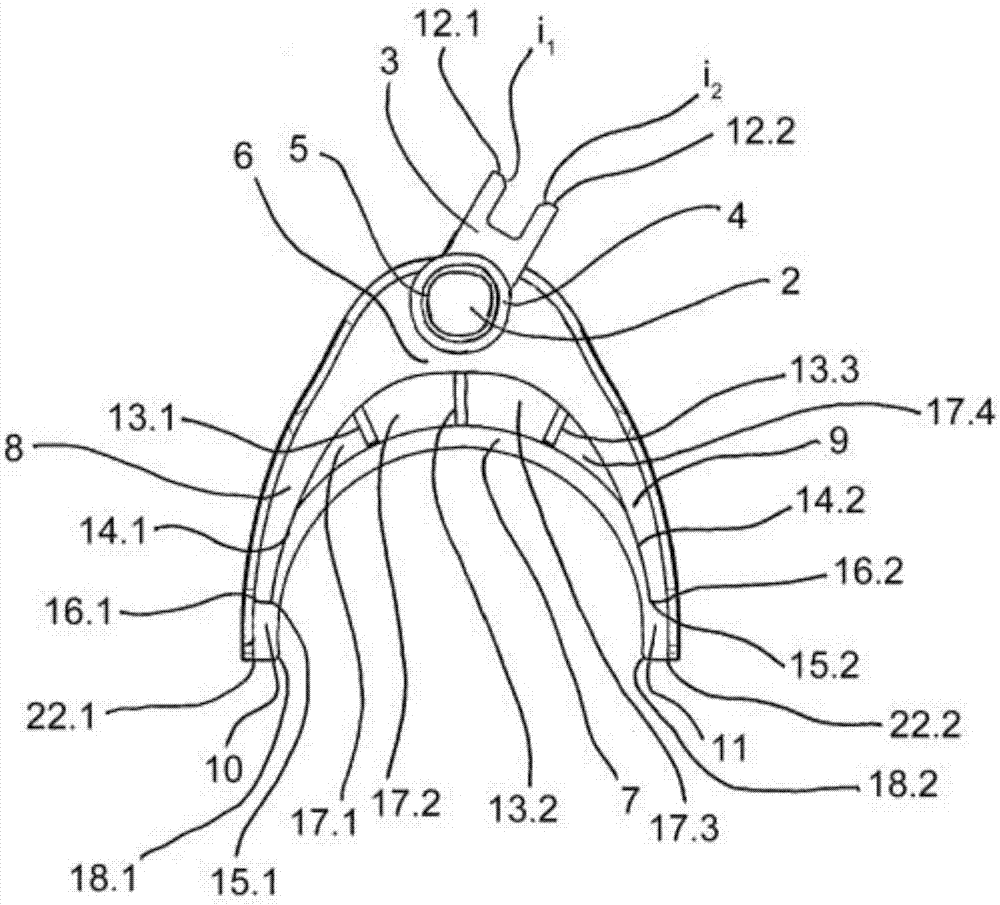

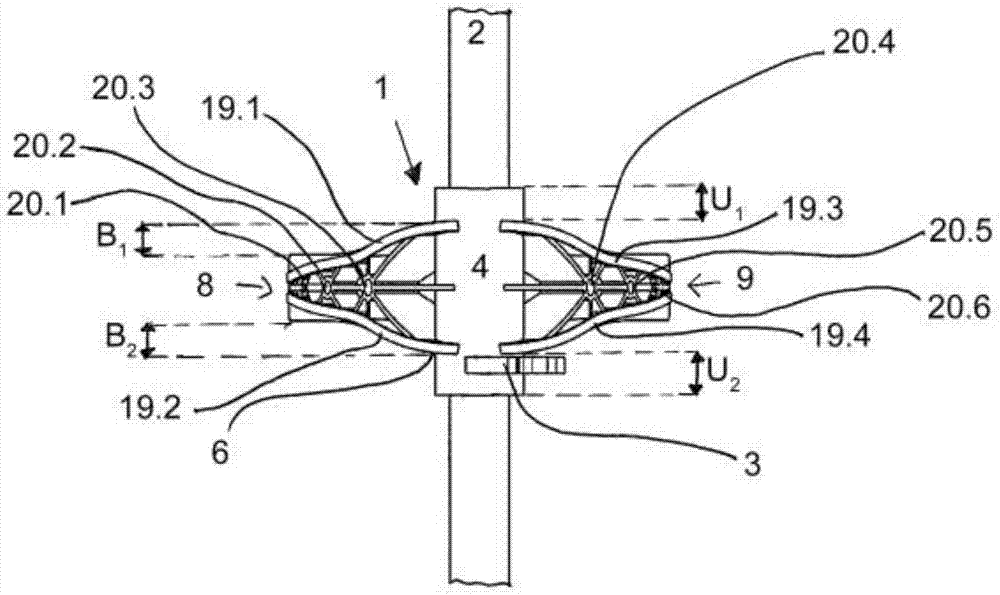

[0036] figure 1 A shift fork 1 according to the invention is shown with a partially shown shift fork shaft 2 . The shift fork 1 has a fork body 6 and a fork-shaped slide 7 . The fork body 6 is divided into two outer legs 8 and 9 . The fork-like carriage 7 is divided into two inner legs 10 and 11 . Outer legs 8 and 9 and inner legs 10 and 11 are integrally formed by plastic. This means that they are extruded from the extruder in one step. Furthermore, the details of the outer legs 8 and 9 and the inner legs 10 and 11 are described in detail in subsequent figures.

[0037] The fork body 6 includes a bush-shaped shift fork socket 4 . On the side facing the shift fork shaft 2 , the selector fork socket 4 is equipped with a bearing 5 , via which bearing the selector fork socket 4 accommodates the shift fork shaft 2 .

[0038] Furthermore, the shift fork socket 4 includes the shift arm 3 . The selector arm 3 is U-shaped and accordingly includes two webs 12.1 and 12.2. The tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com