Embedded layer type plastic frame for display screen to be pushed in and inner plastic frame pressing method of embedded layer type plastic frame for display screen to be pushed in

A technology of display screen and embedded layer, which is applied in the direction of instruments, identification devices, etc., can solve the problems of insufficient buffer, difficult to play a protective role, and damage to the display screen, so as to reduce the impact and avoid the effect of key card friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

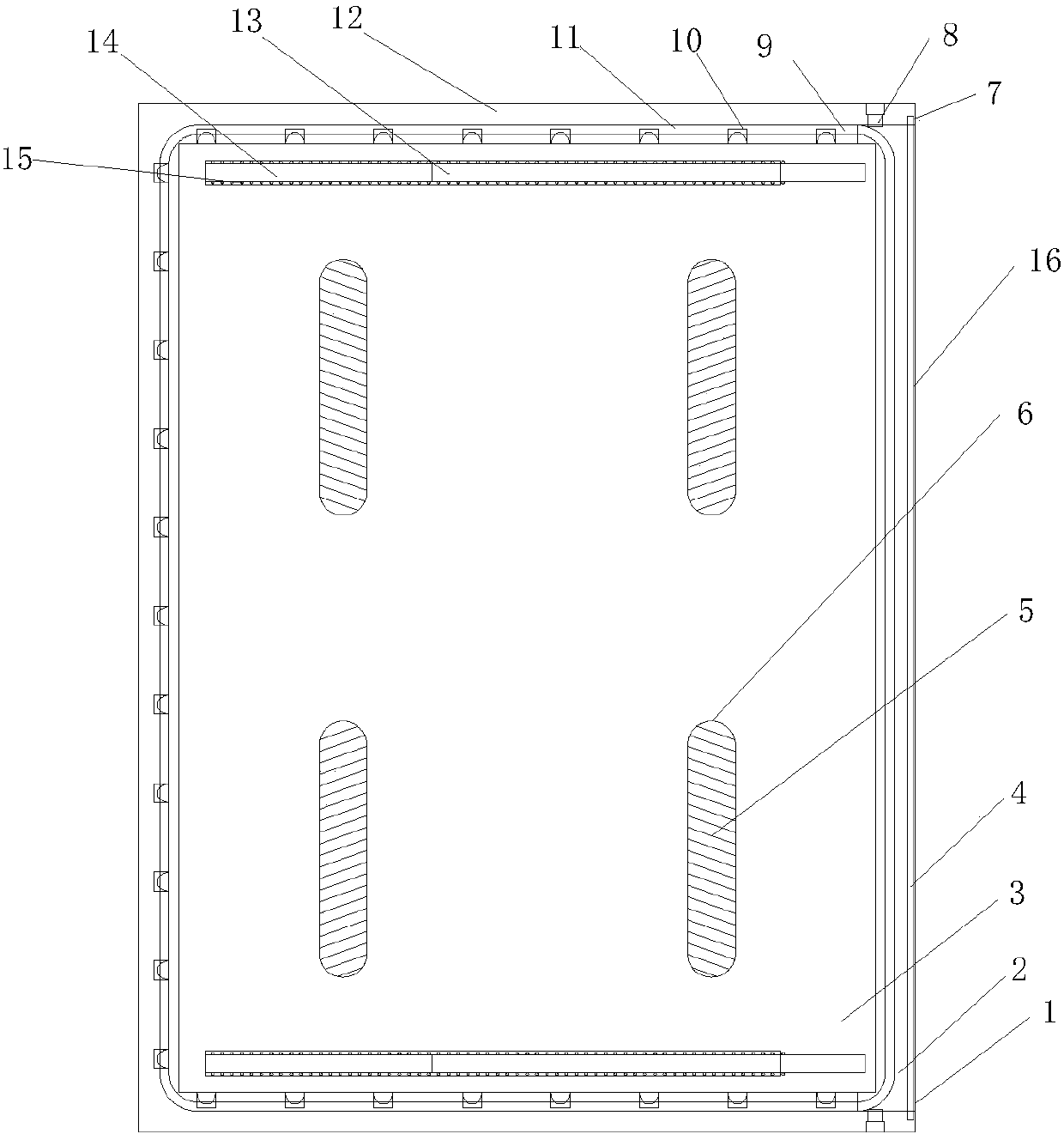

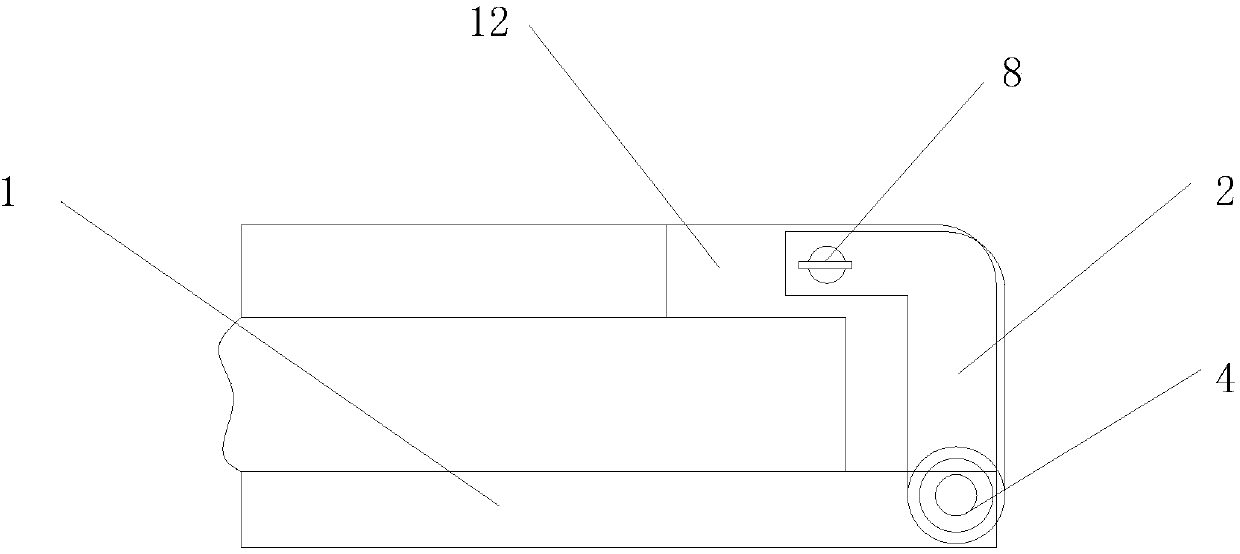

[0030] The method of pressing the inner plastic frame of the embedded layer type into the plastic frame of the display screen, the method of pressing the inner plastic frame is as follows:

[0031] (1) First prepare a certain proportion of plastic adhesive, then evenly apply the plastic adhesive on the contact surface of the inner rubber frame 9 and the outer rubber frame 12, and place the side coated with the plastic adhesive on the inner rubber frame After blowing for 12 seconds, the air outlet is attached to the outer plastic frame 12;

[0032] (2) Pneumatic stamping bonding is performed at the pressing groove 10 at the connection between the inner rubber frame 9 and the outer rubber frame 12 by using a pneumatic stamping block, and during the stamping and bonding, step by step from the middle part of the inner rubber frame 9 to the outer rubber frame 9. The outer pressing process is performed, and then the other parts are evenly flattened by the punching block to complete ...

specific Embodiment 2

[0035] The method of pressing the inner plastic frame of the embedded layer type into the plastic frame of the display screen, the method of pressing the inner plastic frame is as follows:

[0036] (1) First prepare a certain proportion of plastic adhesive, then evenly apply the plastic adhesive on the contact surface of the inner rubber frame 9 and the outer rubber frame 12, and place the side coated with the plastic adhesive on the inner rubber frame After blowing for 15 seconds, the air outlet is attached to the outer plastic frame 12;

[0037] (2) Pneumatic stamping bonding is performed at the pressing groove 10 at the connection between the inner rubber frame 9 and the outer rubber frame 12 by using a pneumatic stamping block, and during the stamping and bonding, step by step from the middle part of the inner rubber frame 9 to the outer rubber frame 9. The outer pressing process is performed, and then the other parts are evenly flattened by the punching block to complete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com