Enhanced elastic composite silk yarn and preparation method thereof

An enhanced and elastic technology, applied in the direction of textiles, papermaking, yarn, etc., can solve the problems of inability to achieve effective cushioning, low shock absorption effect, and large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

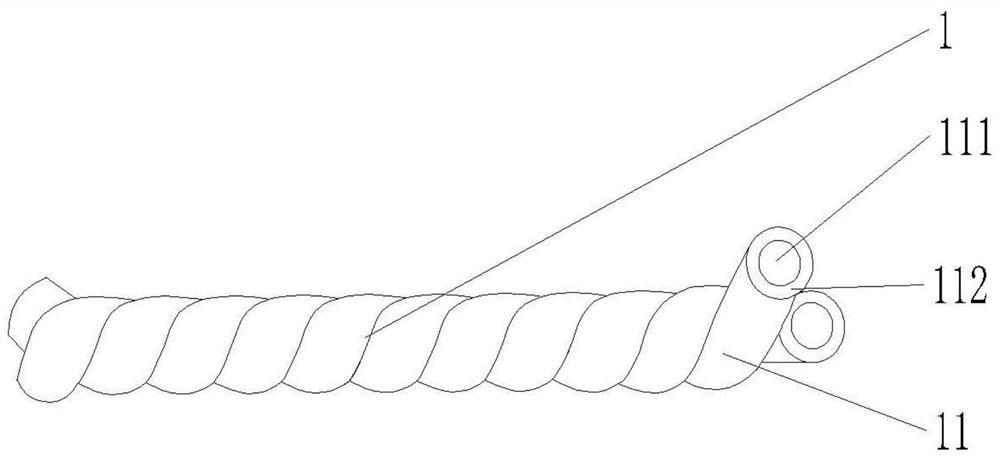

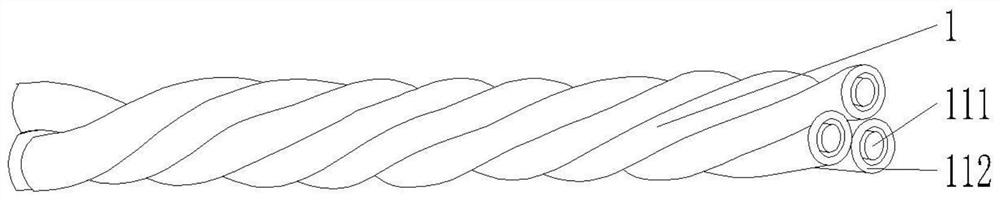

[0025]Such asFigure 1 ~ 3An enhanced elastic composite wire, a line body 1, the wire body comprising: a wire strand 11; the line stock, including: a core 111, an elastic sleeve 112; the core 111, a Fibers that are curved but low, or is a fiber having a bendable but low elongation; the elastic sleeve 112, wraps the core 111; the wire body 1, two or more The line strand 11 is made, two or more of the line strands 11 are wrapped around each other to form a spiral shape.

[0026]Preparation method of enhanced elastic composite wire, its steps:

[0027]Step 1, the wire core is wrapped with a rubber, forming a wire stock.

[0028]Step 2, two or more line stocks are wound, forming a line.

[0029]Preferably, the core 111 is made of glass fiber or made of basalt fiber, or made of carbon fiber, or made of aramid fibers, or made of steel fiber. .

[0030]Preferably, the elastic sleeve 112 is made of rubber.

Embodiment 2

[0032]Preferably, ifFigure 4 As shown, the outer layer of the wire body 1 also has an outer elastic sleeve 2.

[0033]Preferably, the outer elastic sleeve 2 is made of rubber.

[0034]Preferably, further comprising the step three, the wire body is wrapped using an outer elastic sleeve made of rubber to form a whole.

Embodiment 3

[0036]Preferably, further comprising the step three, the wire body is wrapped using an outer elastic sleeve made of rubber, and after the overall vulcanization is bonded, the elastic sleeve is bonded to the outer elastic set, forming an interior having a spiral core, external package. Have a whole (egFigure 5 Indicated).

[0037]The reaction at the time of external force is: a product made from the enhanced elastic composite wire of the present invention, and the spiral formed by the plurality of polygonal wire strands 11 is deform in the straightening direction, so that multiple roots or more The spiral spiral of the beam line 11 is reduced, and the outer flexible material (elastic sleeve) is extruded to each other, until the inland core 111, mutual tightness, to pull the support, avoid further deformation Material production is damaged; when used, it is affected by the pitch of the helix and the thickness of the elastic sleeve.

[0038]The beneficial effect of the present invention is: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com