A method for simultaneous removal of ammonia nitrogen and nitrate nitrogen in water bodies

A technology of nitrate nitrogen and nitrite, applied in the field of environmental governance, can solve problems such as difficulty, high sludge volume, and decreased denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

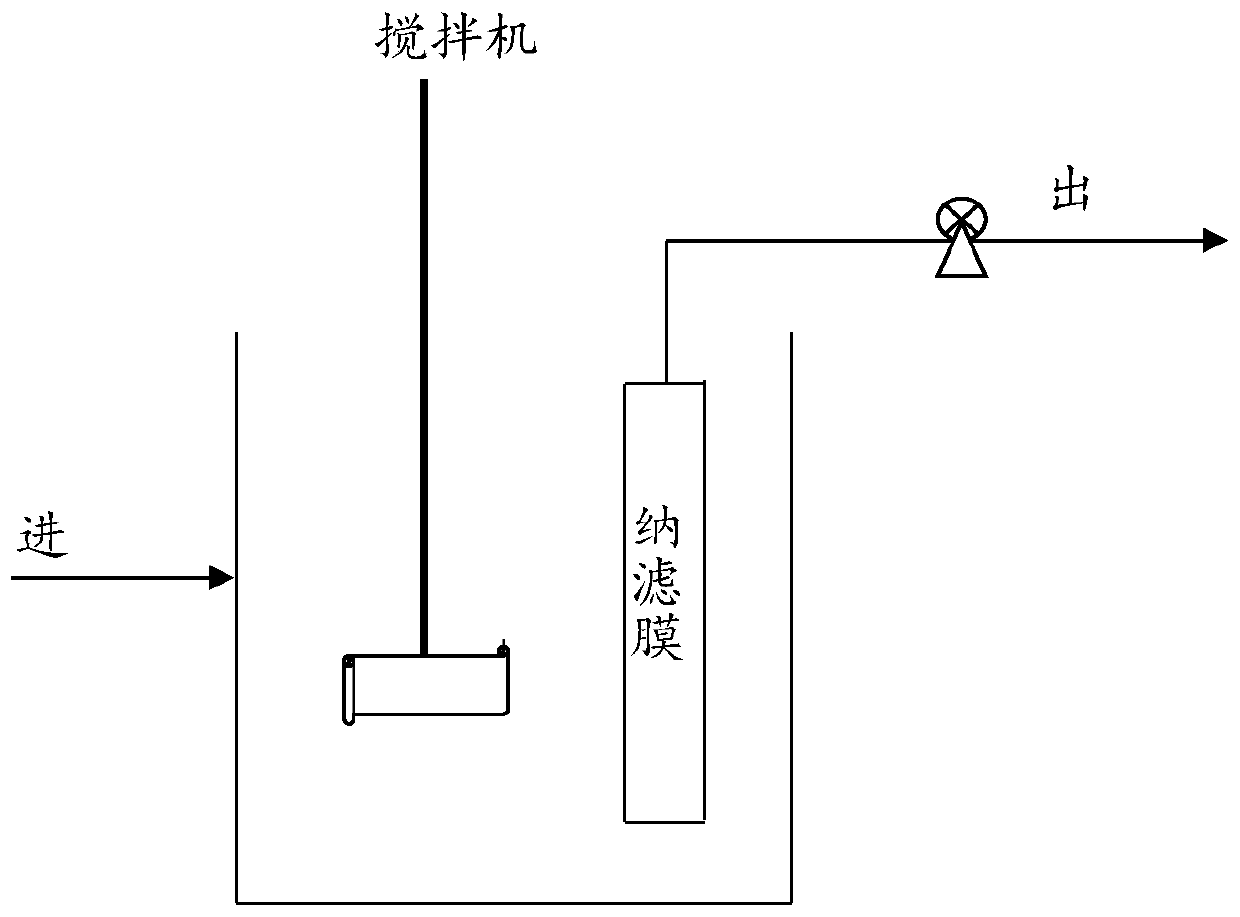

Method used

Image

Examples

Embodiment 1

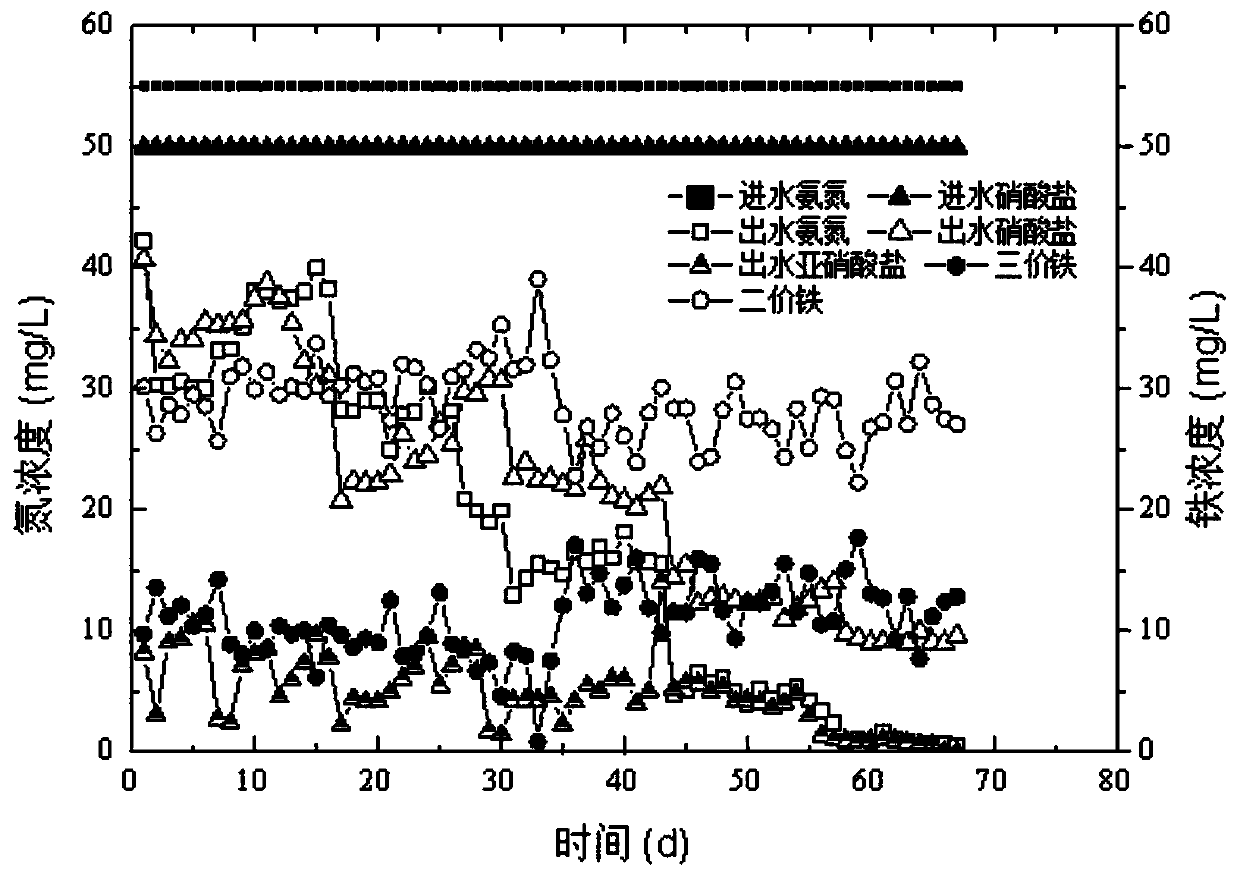

[0045] The main component of simulated wastewater is NH 4 + (by NH 4 Cl provided) 55mg / L and NO 3 - (by NaNO 3 Provide) 50mg / L; Catalyst is ferric ion (by FeCl 3 Provided, based on the volume of the reactor) to be added at a ratio of 50g / L.

[0046] The dissolved oxygen in the simulated wastewater is removed by the high-purity nitrogen aeration deoxygenation method to ensure that the oxygen concentration in the anaerobic ammonium oxidation reactor with stirring function is lower than 0 mg / L, and an anaerobic environment is provided. In the reactor, Anammox sludge, NAFO sludge and Feammox sludge were inoculated to provide anammox microorganisms, iron autotrophic denitrification microorganisms and iron reducing ammonia oxidation microorganisms for wastewater treatment, and the sludge inoculation amount was 5000mgMLVSS / L. The prepared simulated wastewater was fed into the anammox reactor.

[0047] By acid-base adjustment liquid (the HCl solution of 0.5mol / L and the NaOH so...

Embodiment 2

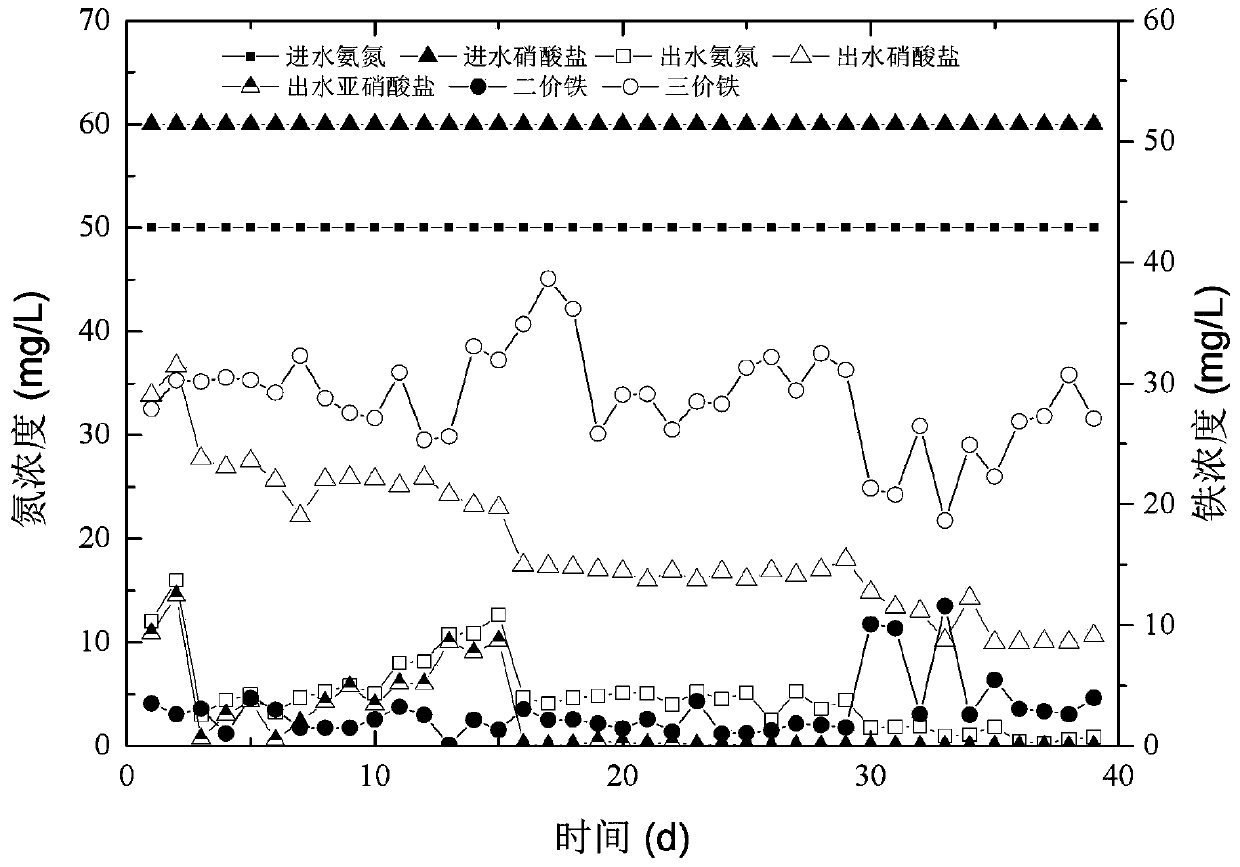

[0050] Prepare simulated wastewater according to the method of Example 1, the main component is NH 4 + (by NH 4 Cl provided) 50mg / L and NO 3 - (by NaNO 3 Provide) 60mg / L; In the reactor, inoculate Anammox sludge, NAFO sludge and Feammox sludge to provide anaerobic ammonium oxidation microorganisms, iron autotrophic denitrification microorganisms and iron reducing ammonia oxidation microorganisms for wastewater treatment, and the sludge inoculation amount is 4500mgMLVSS / L. Provide microbial environment, adjust anaerobic environment, regulate treatment temperature and environmental pH value. The prepared simulated wastewater was fed into the anammox reactor. Nano-iron powder is used as a catalyst for the removal of inorganic nitrogen in wastewater: after the nano-iron powder is added to the reactor, the concentration of iron ions in the reactor is 40mg / L.

[0051] The concentration of ammonia nitrogen (NH 4 + -N concentration) and nitrate nitrogen concentration (NO 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com