A start-up method for synchronously removing carbon, nitrogen and suspended solids in low-carbon source wastewater by using a membrane bioreactor

A membrane bioreactor, suspended solids technology, applied in chemical instruments and methods, biological water/sewage treatment, aerobic and anaerobic process treatment, etc., can solve the problem of low nitrogen removal rate and difficult simultaneous and efficient removal of various pollutants and other problems, to achieve the effect of reducing COD and total nitrogen, saving infrastructure investment and operation management, and efficient removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

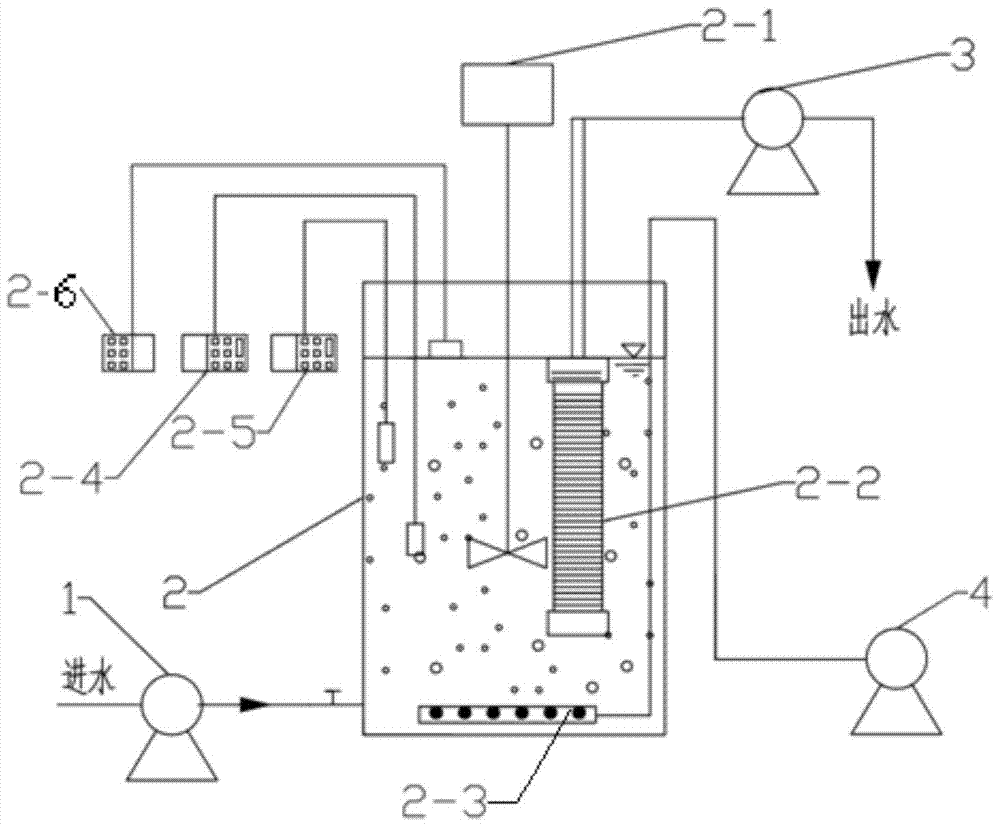

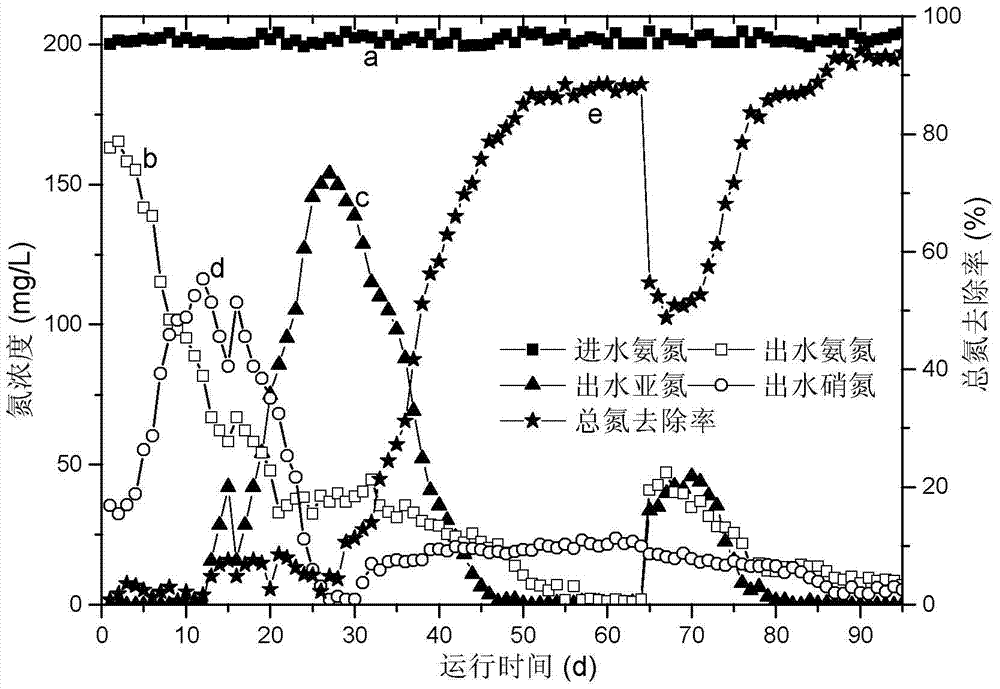

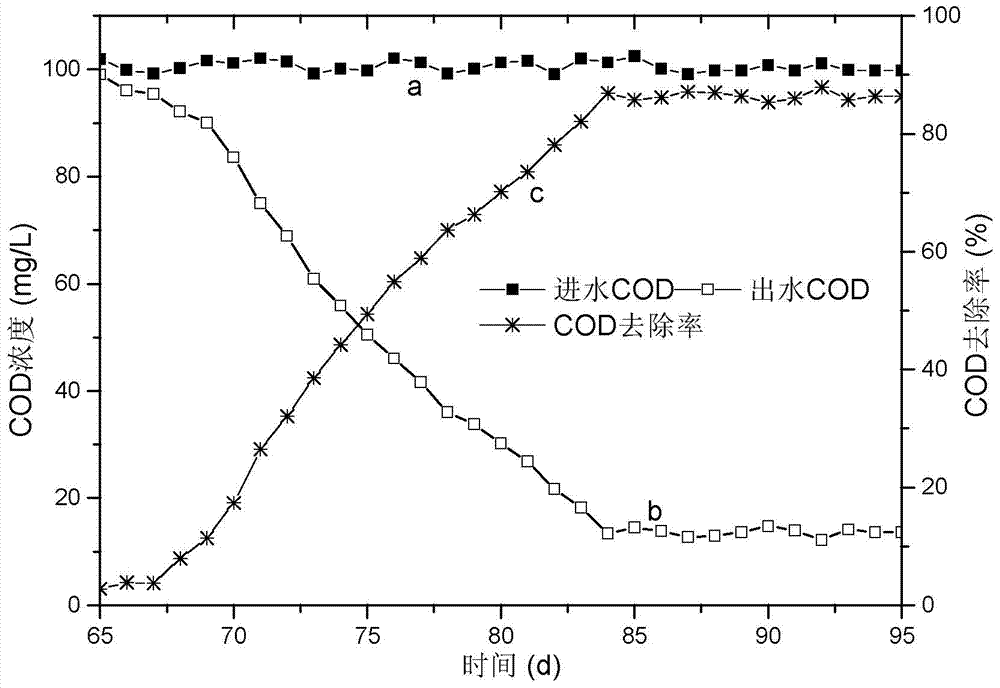

[0015] Specific implementation mode 1: The start-up method of the process of synchronously removing carbon, nitrogen and suspended solids in low-carbon source wastewater by using a membrane bioreactor in this embodiment is carried out according to the following steps:

[0016] 1. Establish a membrane bioreactor water treatment system. The system includes an inlet peristaltic pump 1, a membrane bioreactor 2, an outlet peristaltic pump 3 and an air pump 4. The membrane bioreactor is equipped with a stirrer 2-1 and a membrane module 2- 2. Air distribution device 2-3, DO measuring instrument 2-4, pH measuring instrument 2-5 and liquid level controller 2-6; water inlet peristaltic pump 1 is connected to the water inlet of membrane bioreactor 2, and water outlet peristaltic pump It is connected to the membrane module 2-2 in the membrane bioreactor, and the air pump 4 is connected to the gas distribution device 2-3 in the membrane bioreactor;

[0017] 2. Turn on the influent peristal...

specific Embodiment approach 2

[0025] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the ammonia nitrogen concentration in the artificial water distribution described in step 3 is 215 mg / L. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 4, the carbon-to-nitrogen ratio of the influent is 0.8:1. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com