Post-pouring tape construction method for large-area roof buildings with main girders passing through post-pouring tape

A construction method and technology of post-pouring tape, which is applied to the preparation of building components on site, construction, building structure, etc., can solve the problems of long construction period, high project cost, unusable lower space, etc., to shorten the construction period, Effects of cost saving, good social value and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

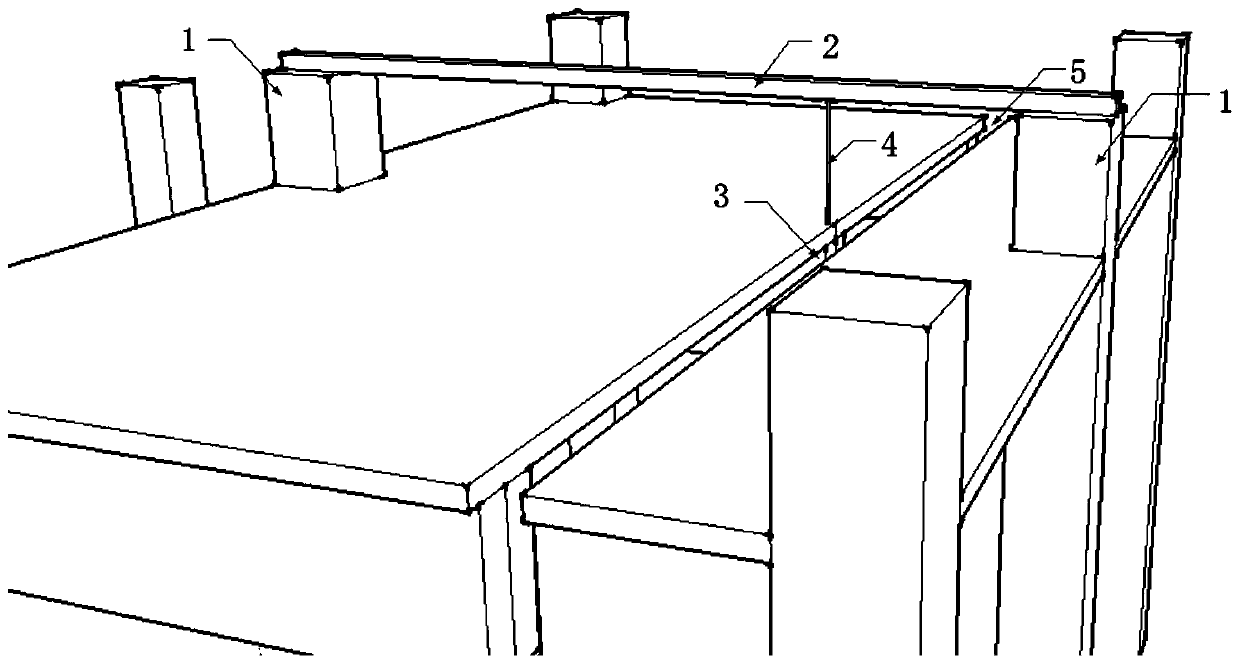

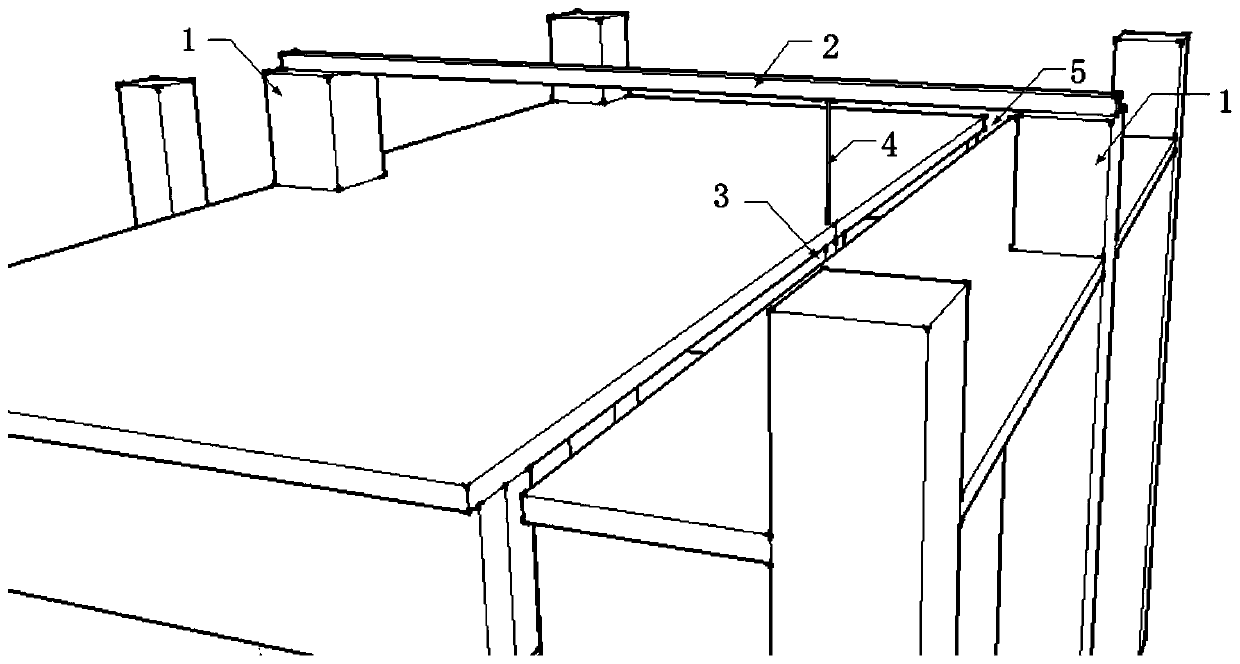

[0021] Such as figure 1 As shown, the post-casting belt construction method of the large-area roof building where the main beam passes through the post-casting belt, the steps are as follows:

[0022] a. Pre-embed the lifting ring at the position where the main beam 3 is located at the post-casting belt 5;

[0023] b. Concrete is poured, and the pre-embedded suspension ring is exposed on the position where the main beam 3 is located at the post-casting belt;

[0024] c. Temporary supports 1 are set on both sides of the post-casting belt 5;

[0025] d. Erection of temporary steel beams 2 on two temporary supports 1;

[0026] e. When the strength of the main beam 3 on both sides of the post-cast belt 5 meets the design requirements, a steel cable 4 is fixed between the temporary steel beam 2 and the embedded lifting ring.

[0027] The present invention is based on the method of setting pre-embedded suspension rings at the position where the concrete main girder 3 passes throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com