Push-pull water diversion valve for engineering geologic drilling water pressing test

A technology of water pressure test and engineering geology, applied in valve details, control valve, valve device, etc., can solve the problem of inability to carry out double-plug continuous water pressure, unable to complete large flow water pressure test, unable to complete drilling water pressure tasks, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

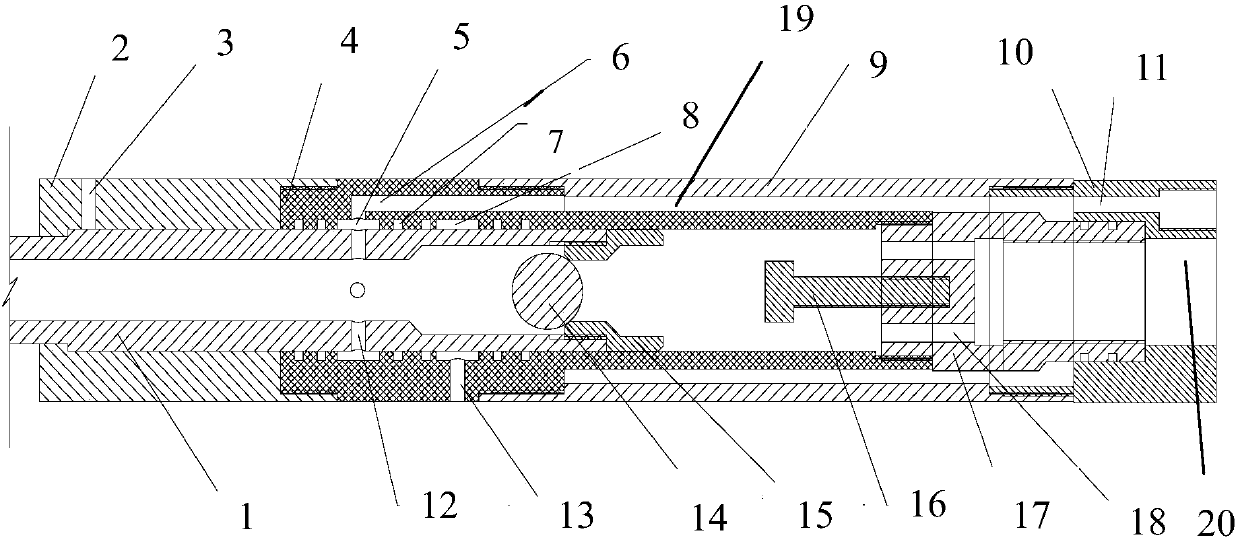

[0012] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0013] Such as figure 1 Shown, the present invention is used for the push-pull type diverter valve of engineering geology borehole pressurized water test, comprises upper valve body 2, lower valve body 4, ball valve seat 15, outer pipe 9, end cover 10, upper valve body 2 lower ends and The upper end of the lower valve body 4 is connected by a screw thread, and the outer wall of the lower valve body 4 is a stepped structure with a thick upper part and a thinner lower part. In the tube 9, an annular cavity 19 is formed, and the lower end of the outer tube 9 is connected to the end cover 10 with the inner through hole 20 and the bypass hole 11 to form a valve chamber; the push-pull core rod 1 is located in the valve chamber, and the lower end is connected to the ball valve seat through a screw. 15. The steel ball 14 is placed between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com