Firefighting bucket water drain valve

A fire-fighting bucket and water-draining valve technology, which is applied to lift valves, valve details, valve devices, etc., can solve the problems of only one-time opening, cannot be opened again, and high power supply requirements, and achieves large water discharge, simple structure, and reduced The effect of blocking area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

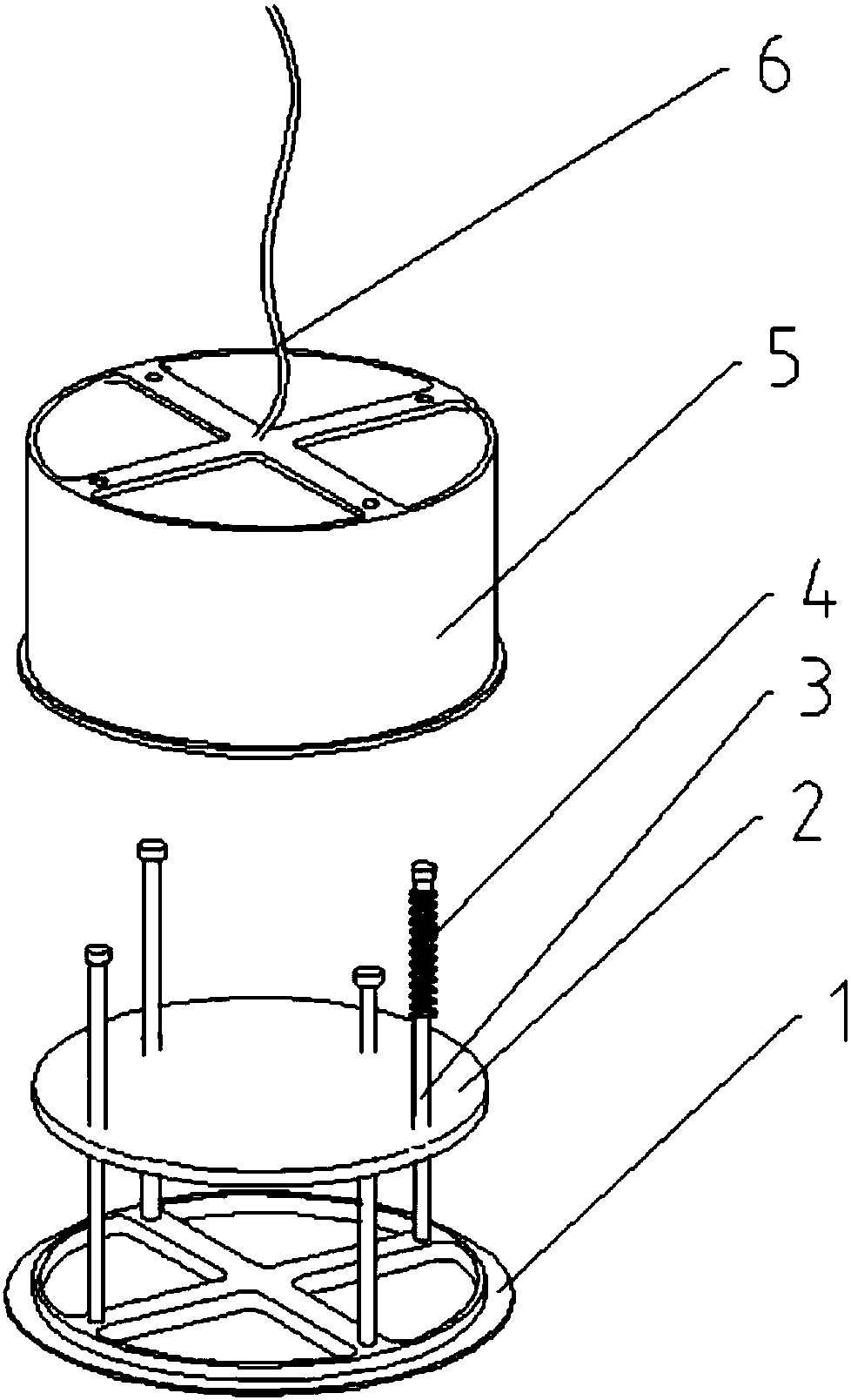

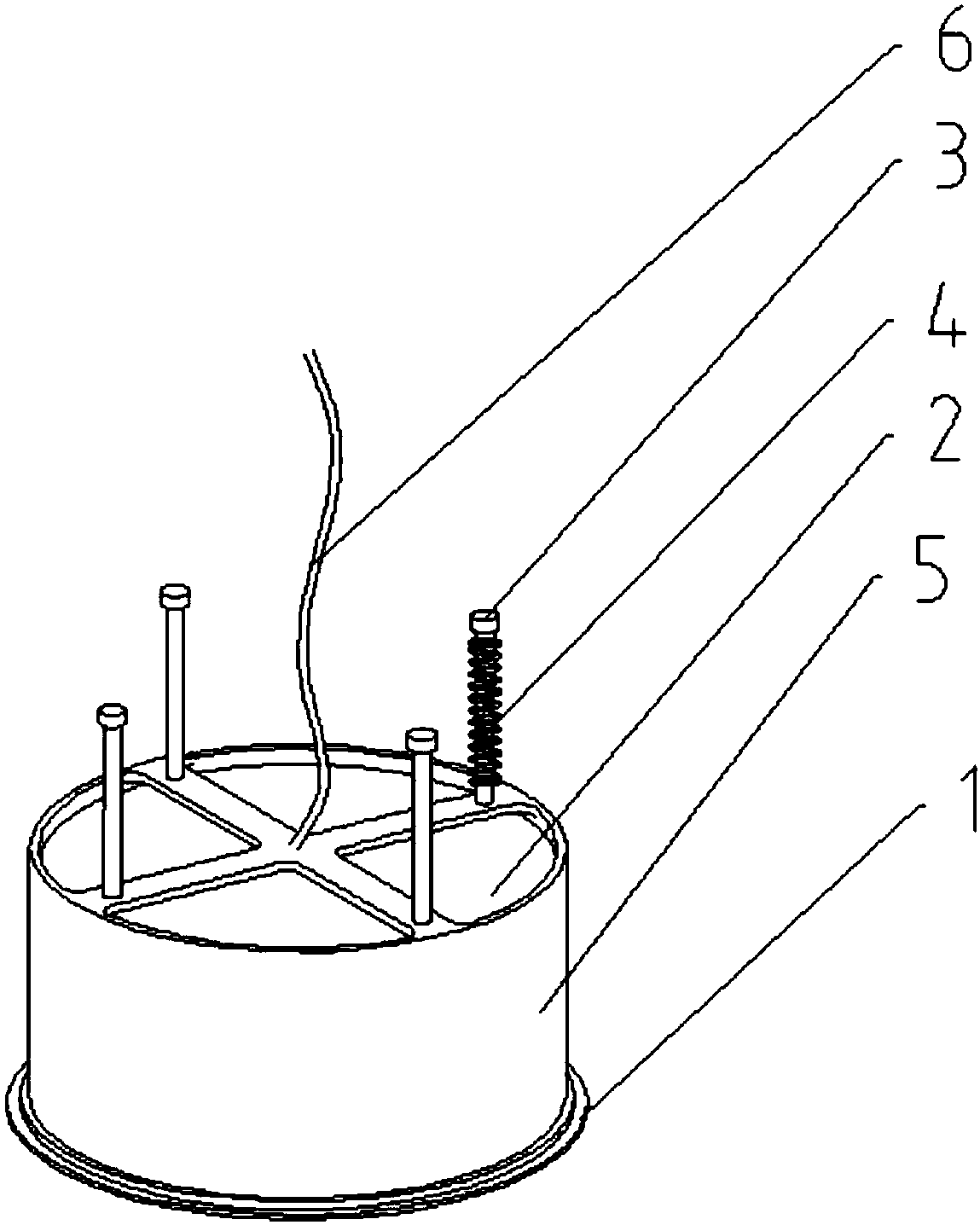

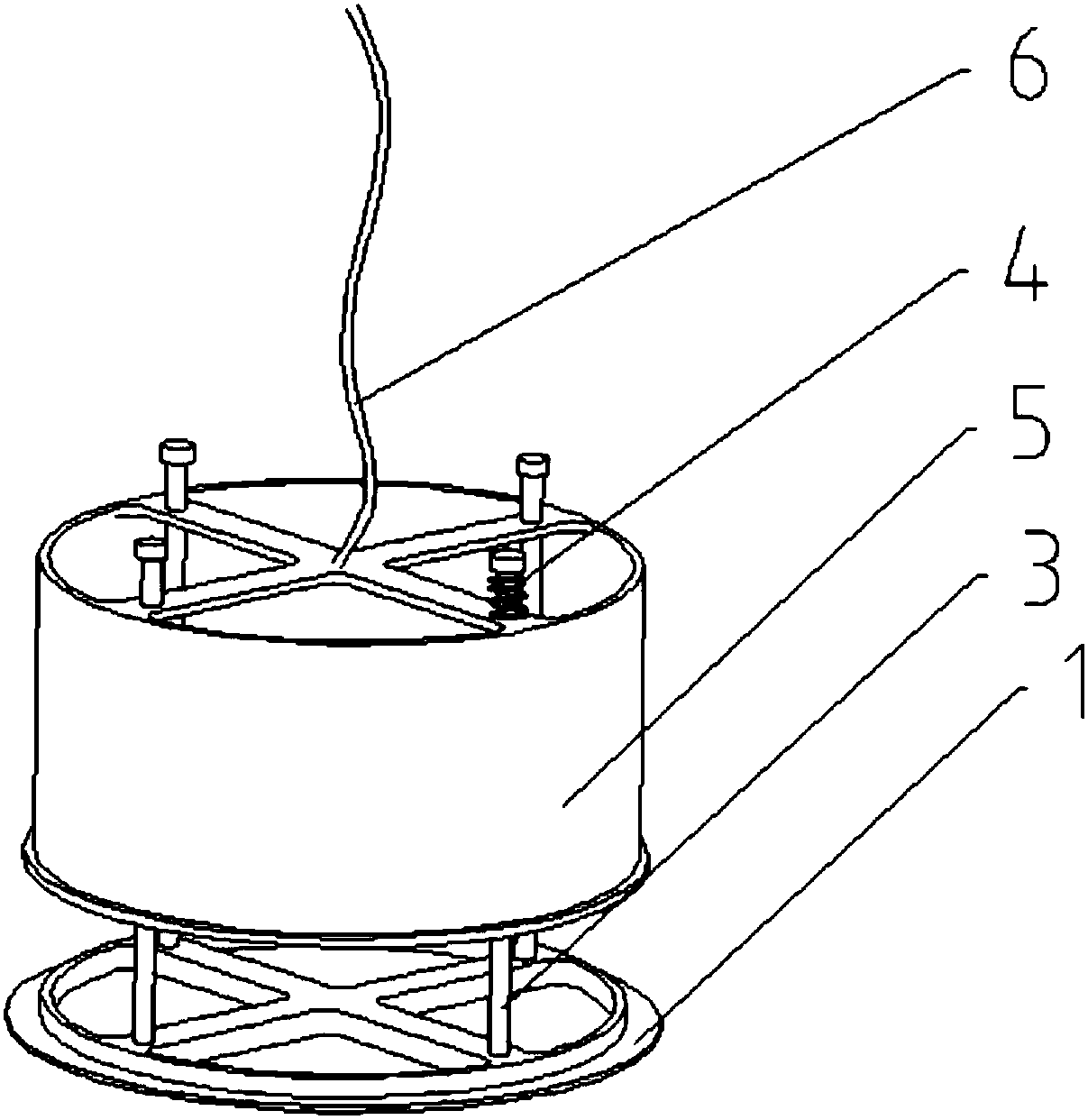

[0015] Such as Figure 1 to Figure 3 As shown, a fire-fighting bucket drain valve includes a valve seat 1 installed on the fire-fighting bucket water outlet, several guide rods 3 fixed on the valve seat 1, a valve core 2 fixed on the guide rod 3, sleeved on the valve The valve body 5 on the core 2 and capable of moving along the guide rod 3, the compression spring 4 that is sleeved on the guide rod 3 and always exerts a force directed to the valve seat 1 on the valve body 5, the water discharge rope 6 connected with the valve body 5, The motor that drives the drain rope 6 up and down, the inner wall of the valve body 5 is always attached to the side wall of the valve core 2 to form a seal, the valve seat 1 and the top and bottom of the valve body 5 are provided with openings, and the bottom of the valve body 5 can be completely attached to the valve A ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com