A phase change cold storage device

A phase change cold storage and cold storage technology, applied in thermal storage equipment, lighting and heating equipment, indirect heat exchangers, etc., can solve the problems of slow heat diffusion, low energy storage and release speed, and low thermal conductivity of eutectic salt materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Carry out further detailed description below in conjunction with accompanying drawing:

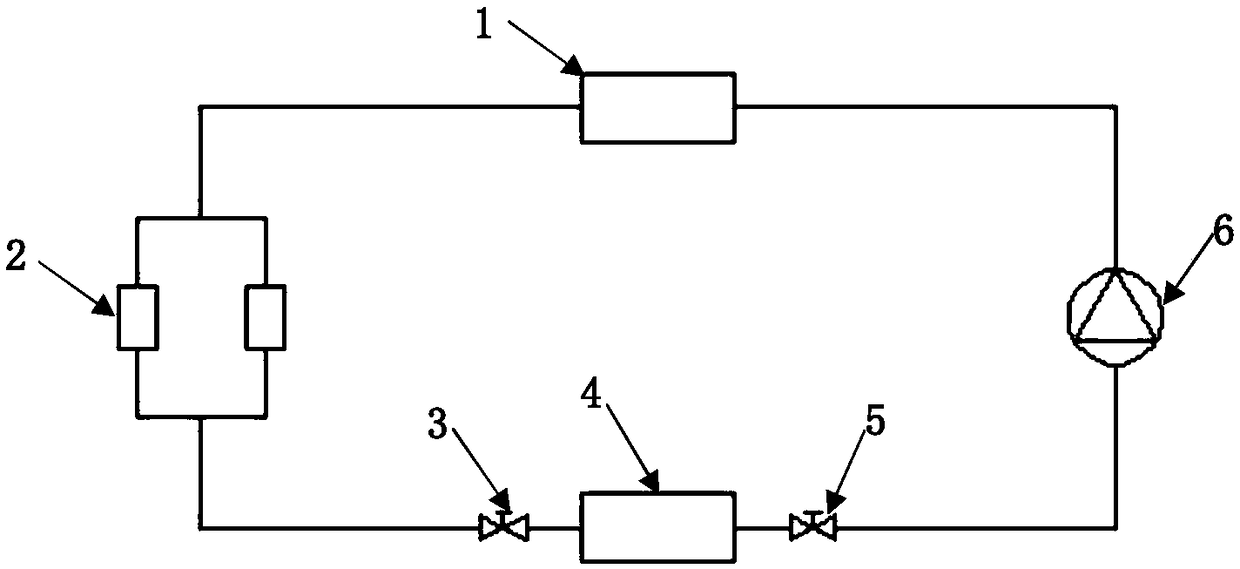

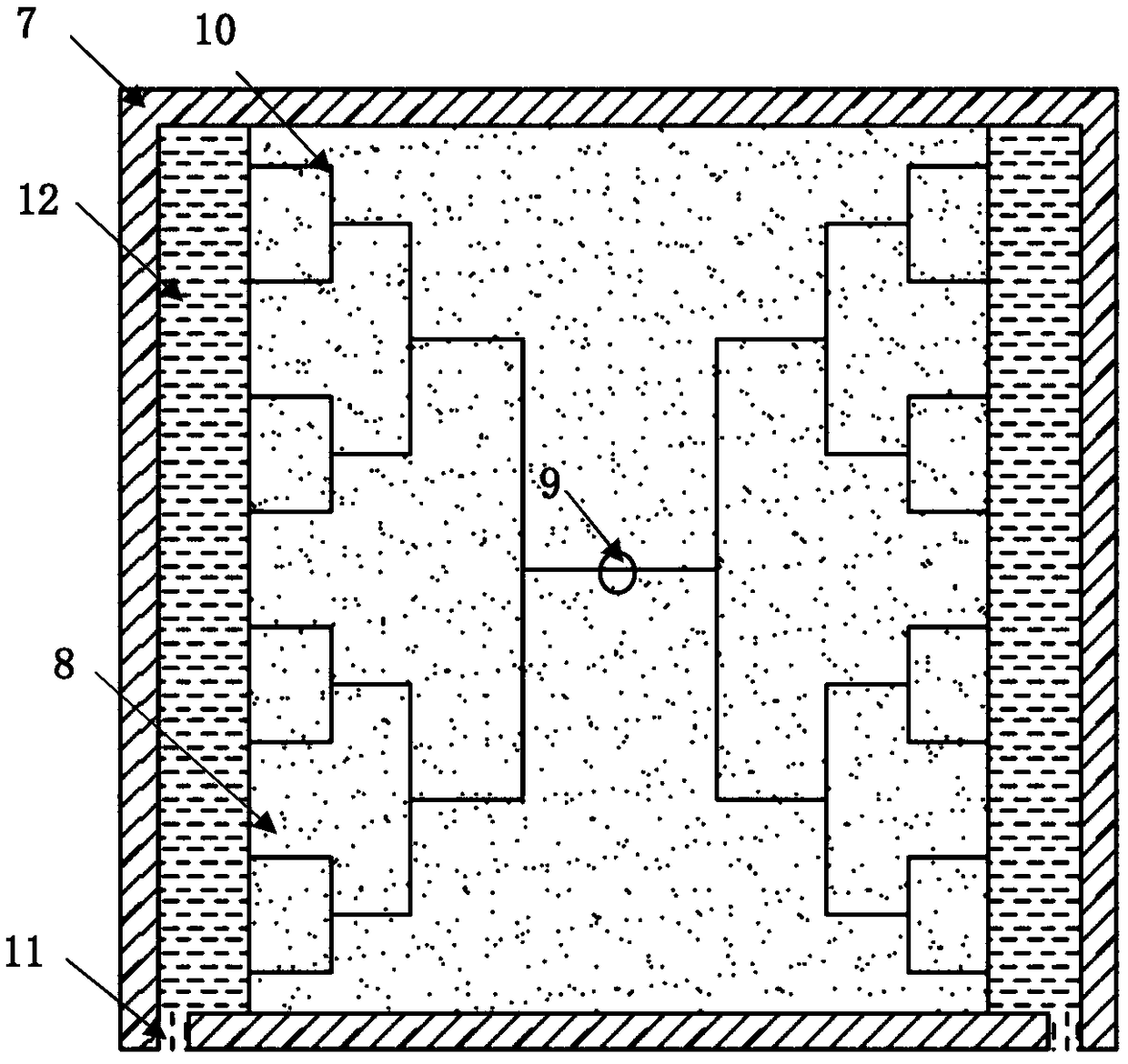

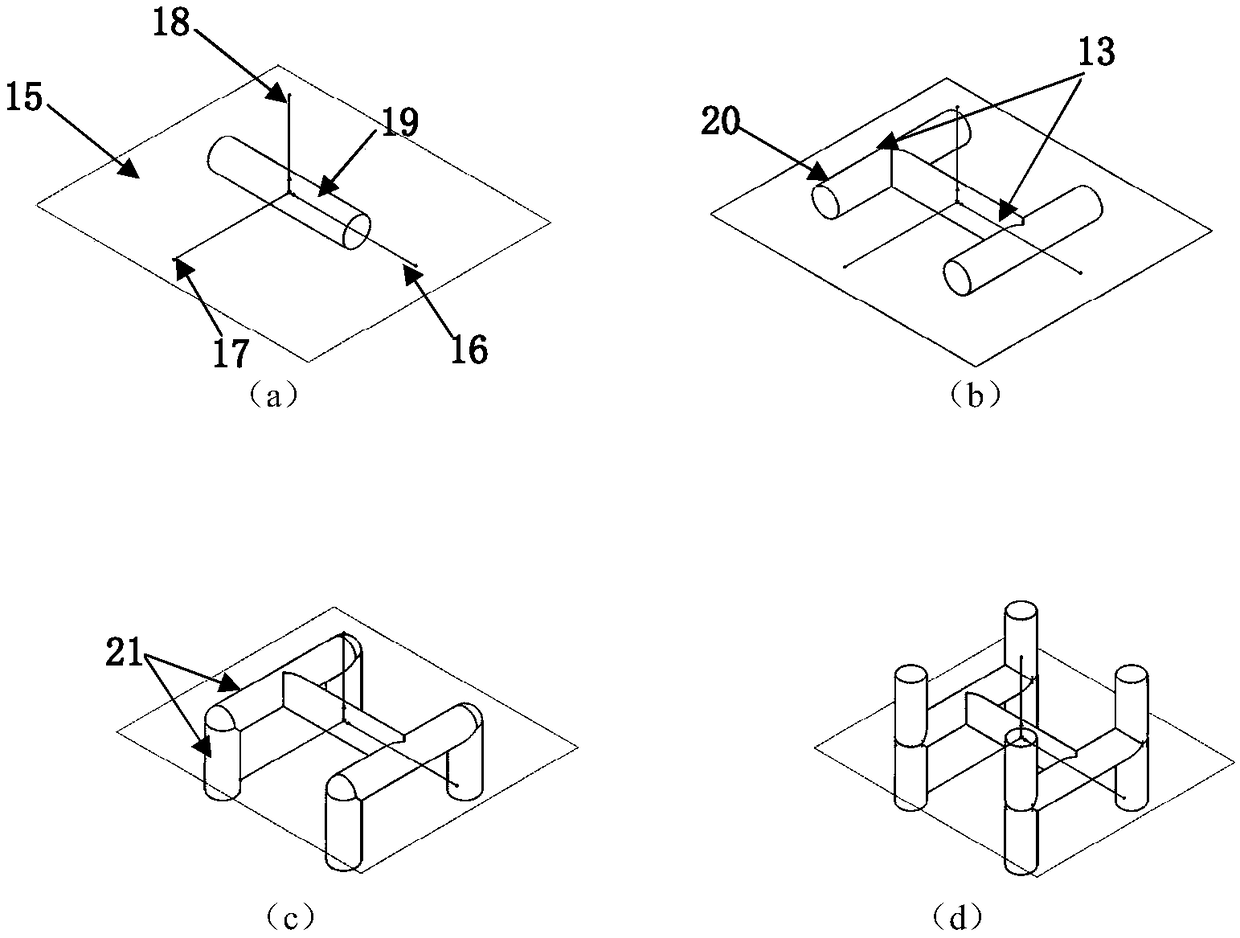

[0039] figure 1 A schematic diagram of the eutectic salt phase change cold storage device is given, including two parts, the cold storage module and the external circulation module. During the power valley period, the chiller 2 is powered and starts to run to generate cold water. Open the pressure stabilizing valve 3, cold water enters the cold storage tank 4 through the pressure stabilizing valve 3, and uses the eutectic salt phase change material 8 packaged in the cold storage tank 4 to store cold in phase change. When the pressure behind the regulator valve 3 increases, the valve opening of the regulator valve 3 decreases; when the pressure behind the regulator valve 3 decreases, the valve opening of the regulator valve 3 increases. The cold water leaves the cold storage tank 4, passes through the check valve 5, and returns to the chiller 2 under the action of the water pump 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com