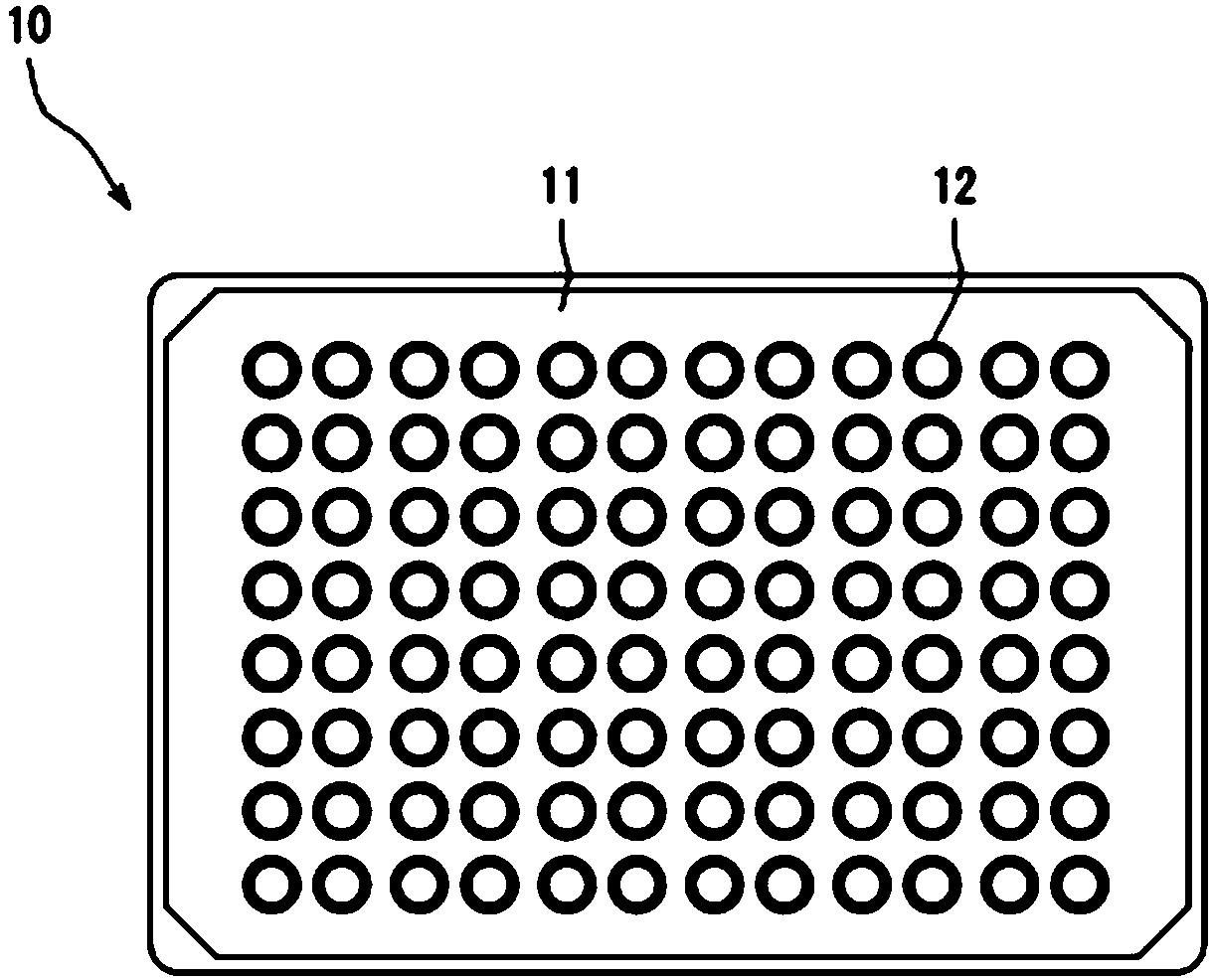

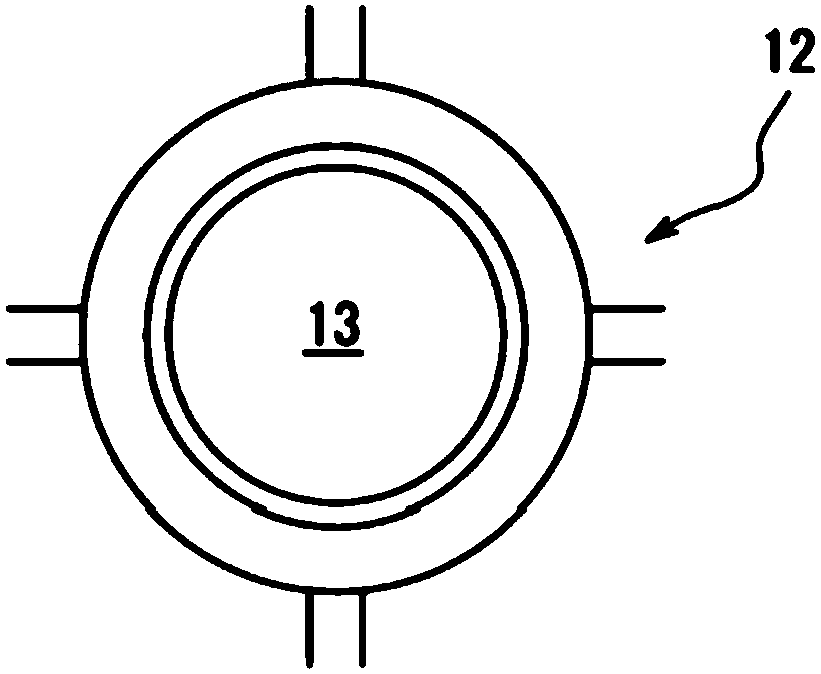

Well plate and method of using the same

A technology of orifice plate and stepped part, which is applied in the field of orifice plate, can solve the problems of high lens manufacturing cost and the inability to include the whole object in the focus range, etc., and achieve the effect of improving visibility, avoiding complexity, and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

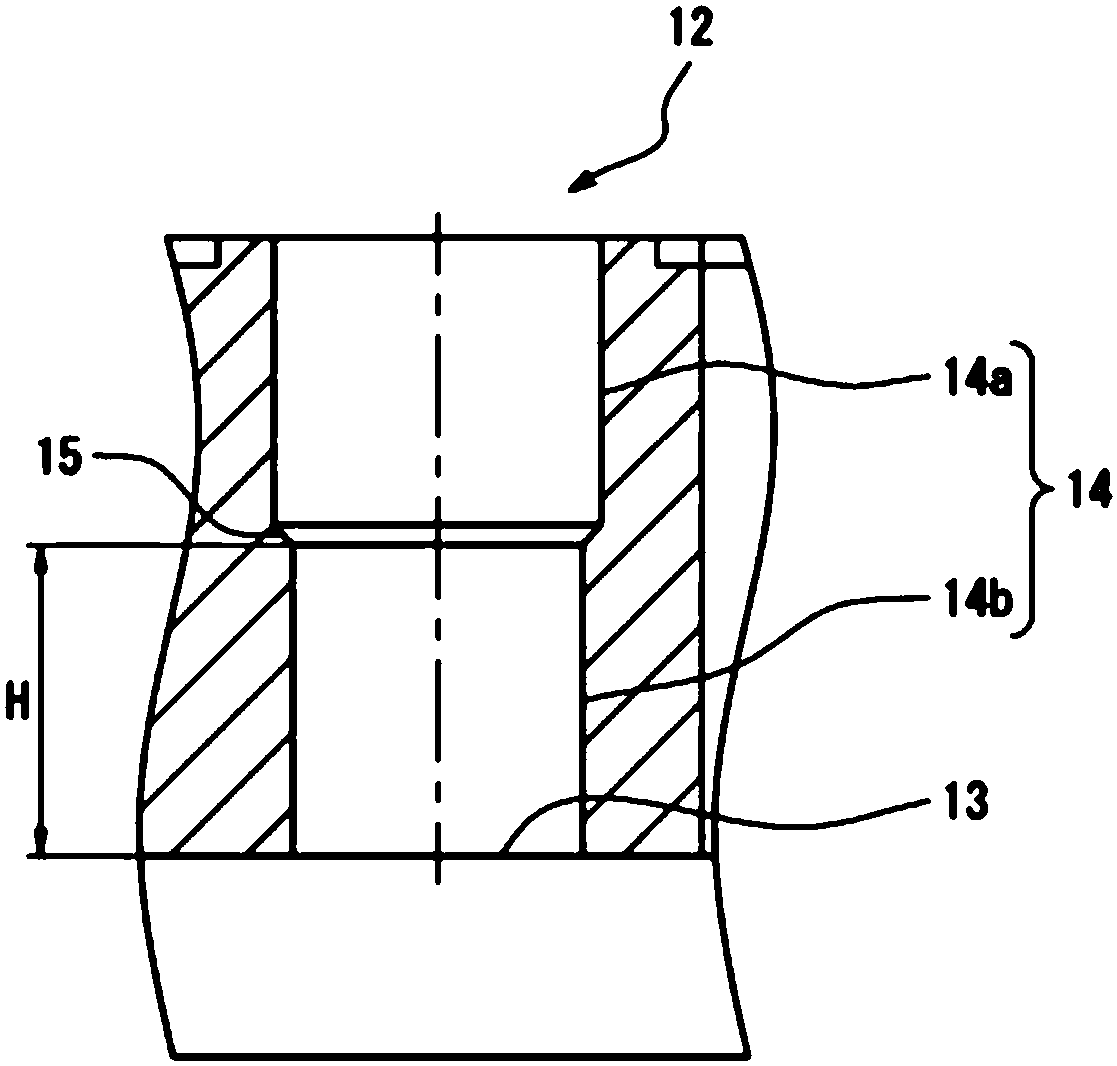

[0058] In this example, an orifice plate of the following specifications made of acrylic resin was used as the orifice plate. It should be noted that, as the holes, holes in which the upper portion of the peripheral wall and the lower portion of the peripheral wall stand approximately perpendicularly to the bottom surface portion were used.

[0059] The inner diameter of the upper part of the surrounding wall: 5.6mm

[0060] Inner diameter of the lower part of the surrounding wall: 5mm

[0061] The inclination angle of the step part: 0 degrees

[0062] Well volume: 250μl

[0063] The volume of the lower part of the surrounding wall: 50.04μl

[0064] The height position of the step part: 2.55mm from the bottom face

[0065] The depth of the hole (the distance from the bottom surface to the opening): 10.8mm

[0066] 100 µl of DMEM (Dulbecco's Modified Eagle's Medium) as a culture solution was dropped into the wells of the aforementioned well plate, and the bottoms of the we...

Embodiment 2

[0068] In this example, as the orifice plate, an orifice plate having the following specifications was used. Except for this, it carried out similarly to Example 1, and photographed the surface of a hole bottom with the inverted microscope. show the result in Figure 7 .

[0069] The inner diameter of the upper part of the surrounding wall: 5.6mm

[0070] Inner diameter of the lower part of the surrounding wall: 5mm

[0071] The inclination angle of the step part: 45 degrees

[0072] Well volume: 250μl

[0073] The volume of the lower part of the surrounding wall: 50.04μl

[0074] The height position of the step part: 2.55mm from the bottom face

[0075] The depth of the hole (the distance from the bottom surface to the opening): 10.8mm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com