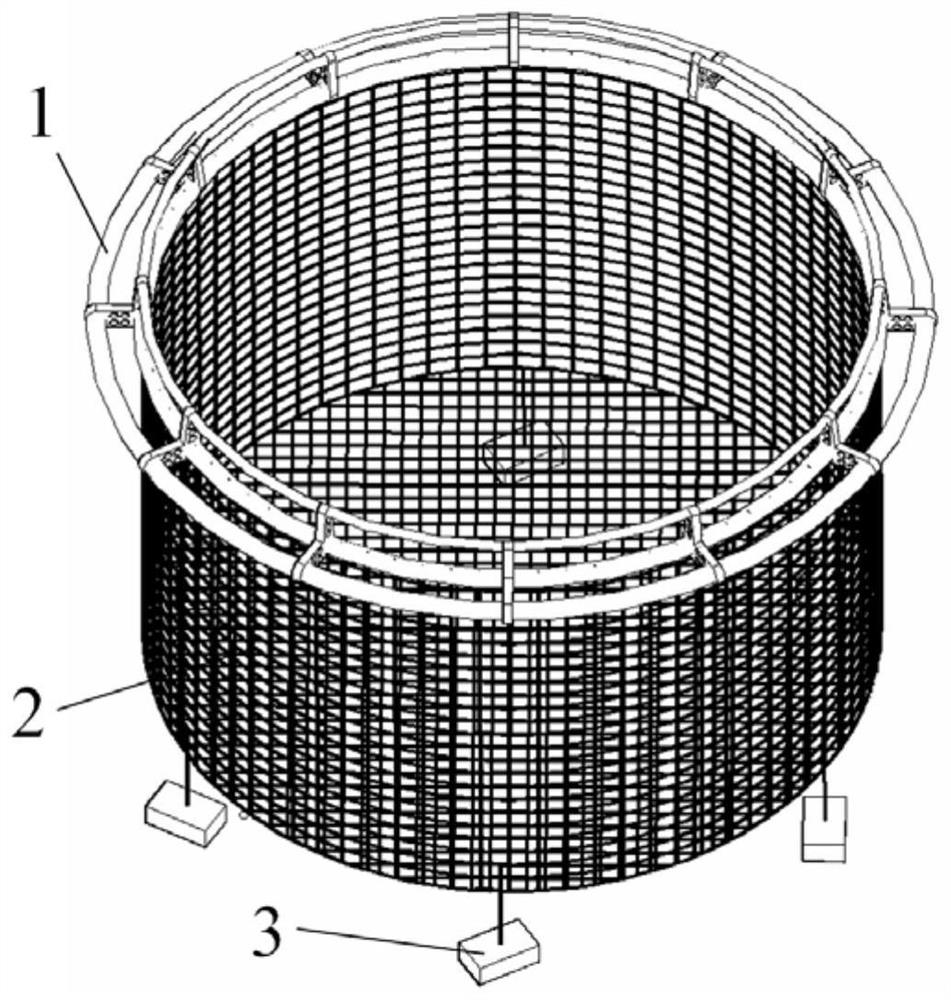

Anti-flow cage system with detachable bottom net and side net

A bottom net and cage technology, applied in application, climate change adaptation, fish farming and other directions, can solve the problems of poor personal safety and high labor intensity of breeding workers, and achieve convenient breeding operations, reduce labor intensity, and reduce net pulling. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

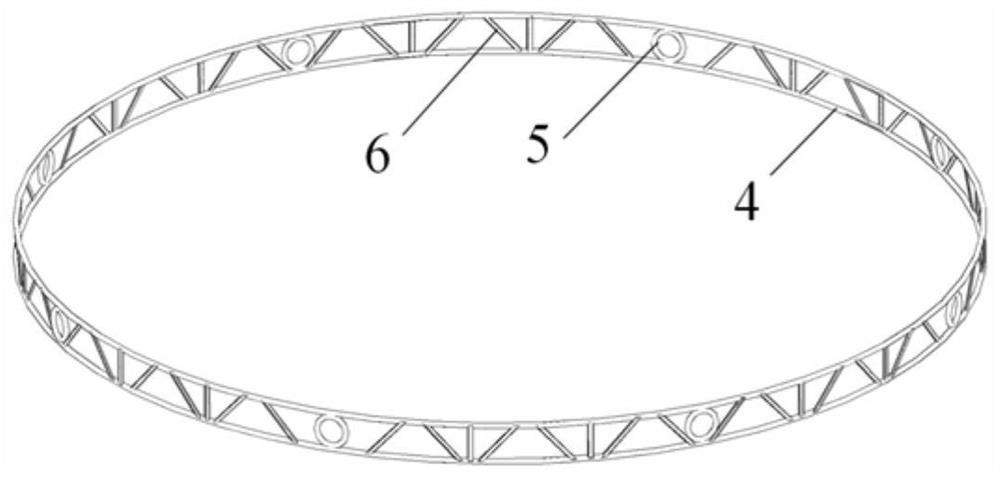

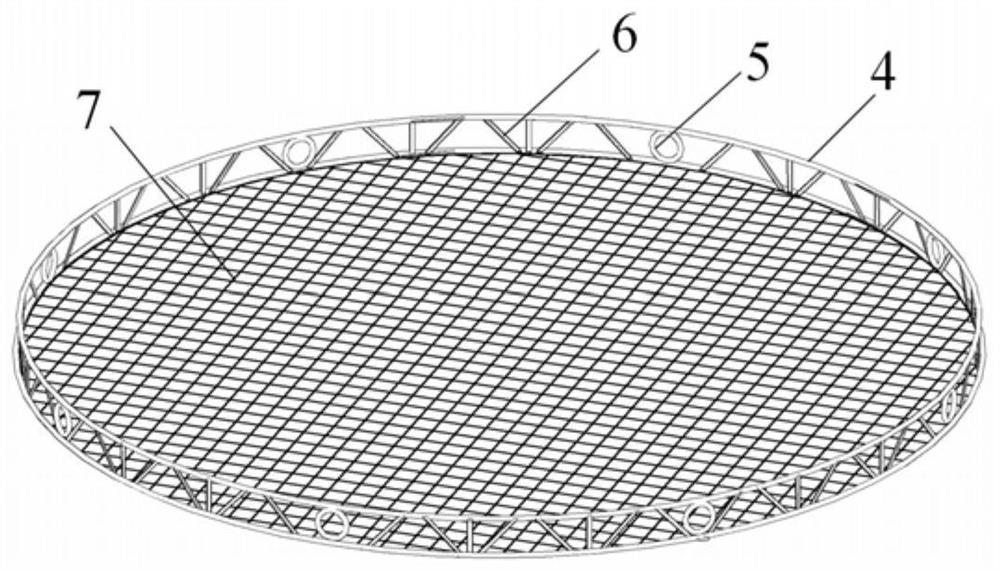

[0073] Embodiment 1: as Figure 2~Figure 13 As shown, 8 mooring rings 5 are evenly and symmetrically arranged on the bottom net frame 4, correspondingly using 8 steel wire ropes 11 to moor between the bottom net frame 4 and the cage frame 1, and the length of the sleeve 8 is about 1 / 4 of net depth, net cage uses 32 sleeves 8 altogether. The schematic diagram of the proposed device after installation is shown in Figure 11 shown.

Embodiment 2

[0074] Embodiment 2: 12 mooring rings 5 are evenly and symmetrically arranged on the bottom net frame 4, and 12 steel wire ropes 11 are used correspondingly to moor between the bottom net frame 4 and the cage frame 1, and the length of the sleeve 8 is about For 1 / 3 of net depth, net cage uses 36 sleeves 8 altogether.

[0075] According to the above ideas, more embodiments can be derived, which are not exhaustive here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com