Logistic weighing and sorting system

A sorting system and logistics technology, applied in sorting and other directions, can solve the problem that the information of the staff running back and forth to load the goods cannot be fed back in time, and achieve the effect of easy intelligent application, convenient use and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

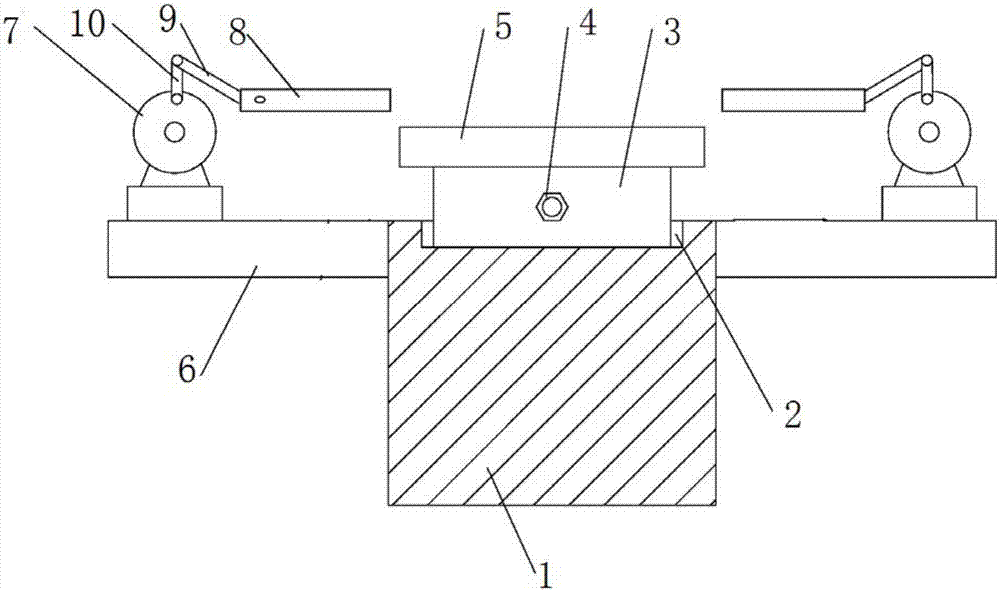

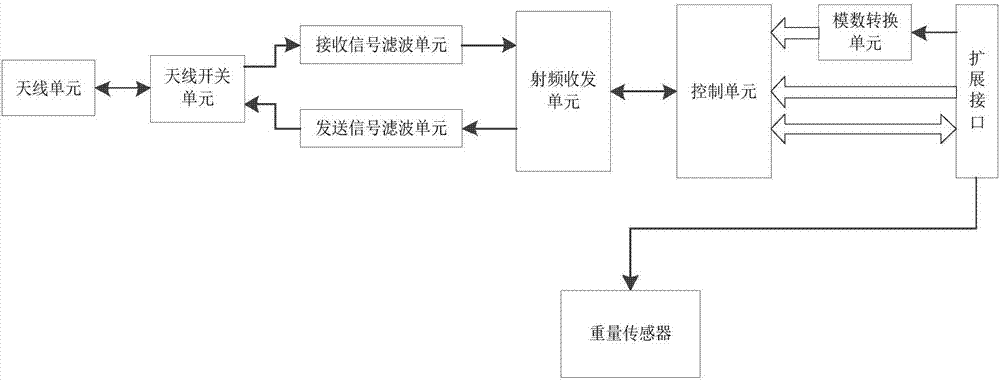

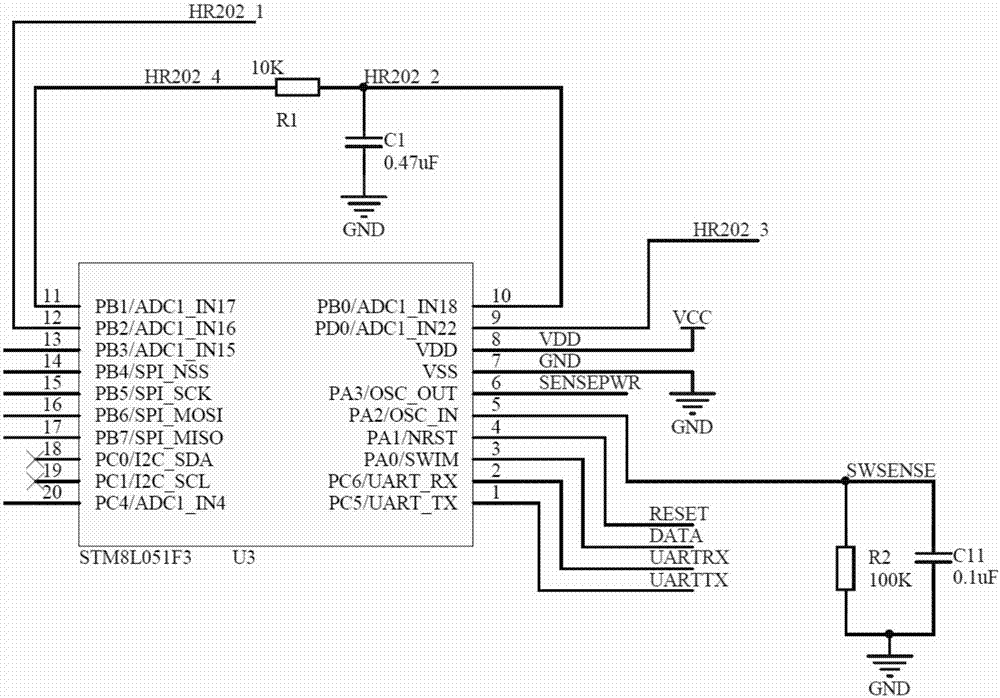

[0018] refer to Figure 1 ~ Figure 3 Shown: a logistics weighing and sorting system, including a base 1 and a tray 5 arranged on the base 1, the tray 5 is provided with an electronic label module, the electronic label module is fixed on the bottom of the tray 5 through the housing 3, and the base 1 The shell 3 with the groove 2 embedded in the groove 2 on the base 1 is locked by the locking nut 4 to prevent movement. Two sides of the tray 5 are provided with manipulators for grabbing and placing materials. The manipulators include a swing assembly and a gripper 8 connected thereto. The swing assembly is driven by a motor. The swing assembly includes a turntable 7, a turning rod 10, and a swing rod 9. The turntable 7 is fixed on the output shaft of the motor, and the lower end of the turn lever 10 is fixed on the edge of the turntable 7 to form an eccentric rotation structure. The swing One end of the rod 9 is rotatably connected to the upper end of the rotating rod 10 , and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com