Surface cleaning equipment

A technology for surface cleaning and equipment, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc. problems, to achieve the effect of improving production efficiency, improving control accuracy, and ensuring product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

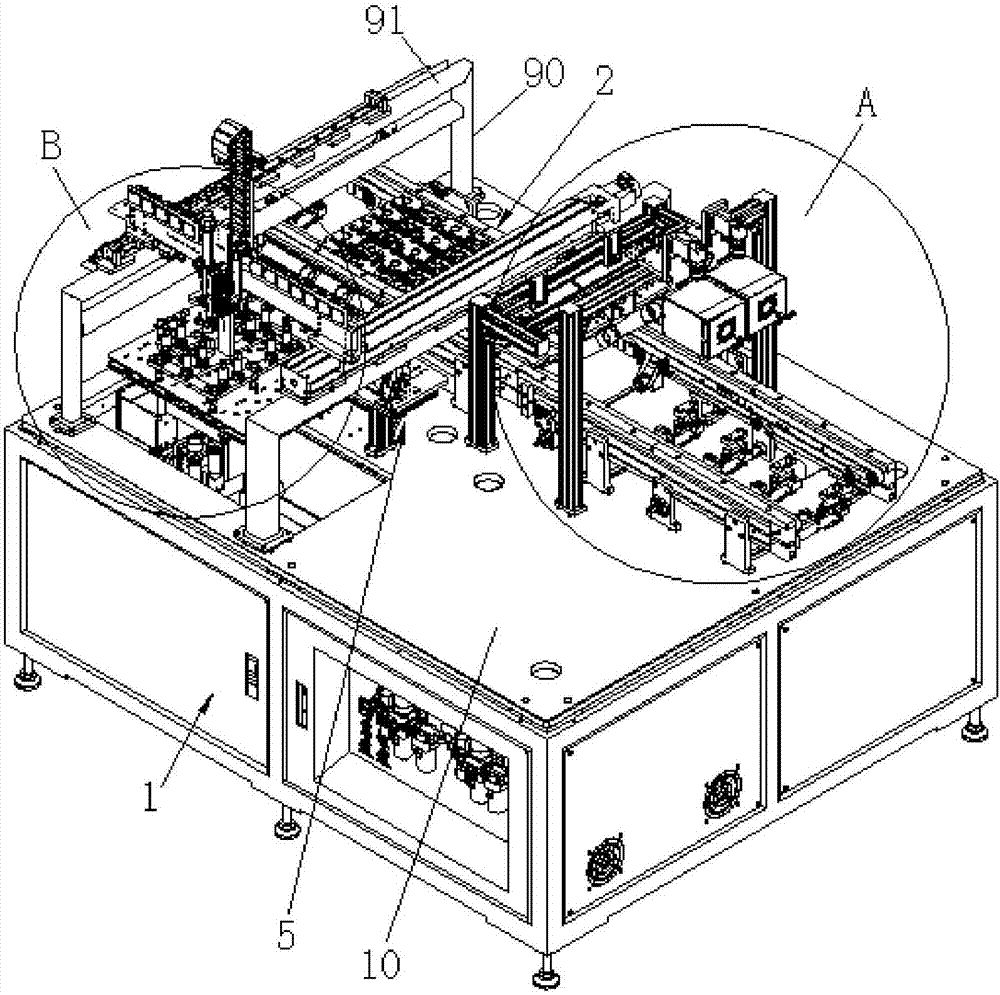

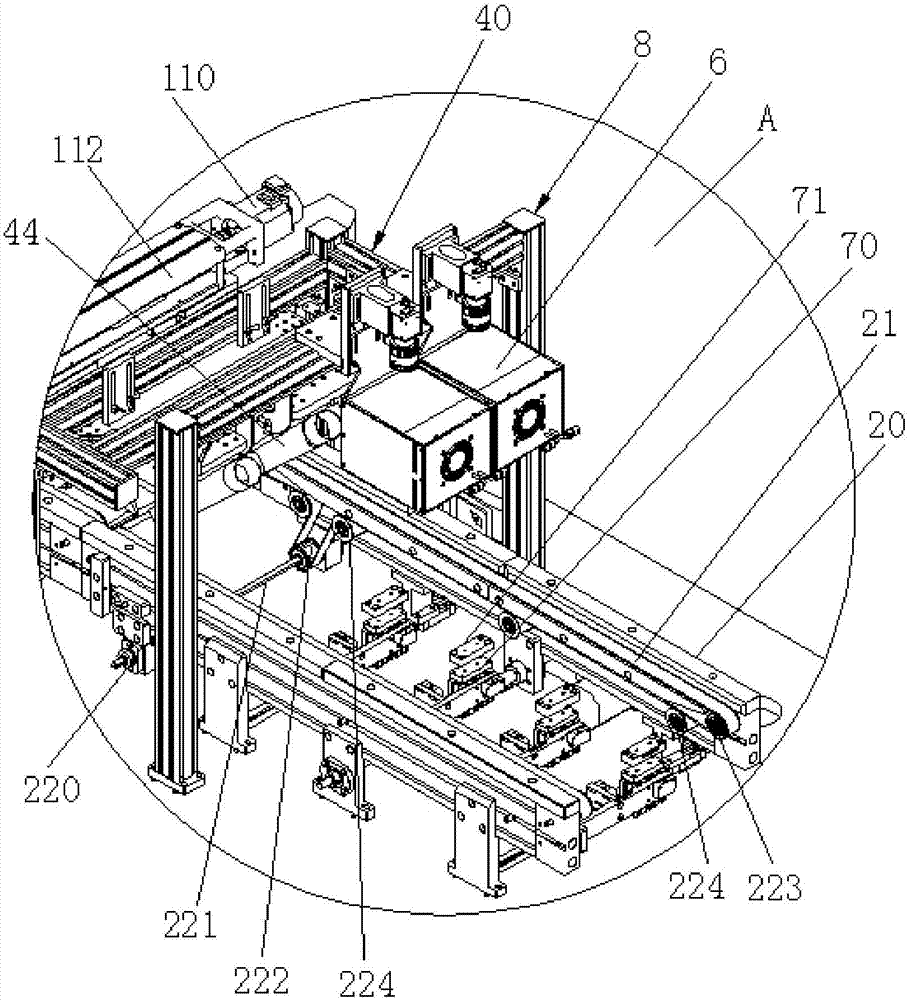

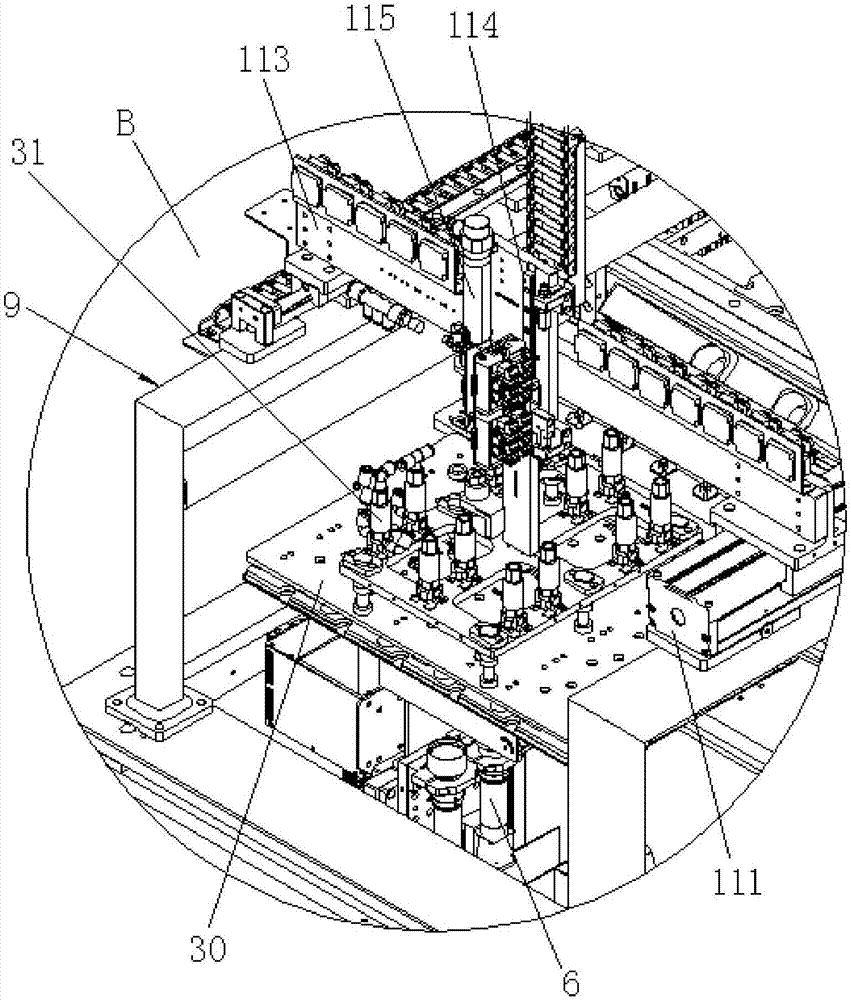

[0055] See attached figure 1 , Attached figure 2 , Attached image 3 And Figure 4 As shown, they are respectively a three-dimensional structural schematic diagram of the surface cleaning device of the present invention in a first angle of view, figure 1 The enlarged structure diagram of part A shown, figure 1 The enlarged schematic diagram of the structure of part B and the three-dimensional schematic diagram of the surface cleaning device in a second perspective are shown.

[0056] The surface cleaning equipment is used to clean the surfaces of a plurality of FPC boards placed in the carrier tray. The surface cleaning equipment includes a base box 1, a conveyor line mechanism capable of conveying the carrier tray 2, and a transport line The gripping assembly 3 for gripping the carrier plate in the upstream feeding area of the mechanism 2, wherein a horizontal working platform 10 is provided on the top side of the base box 1, and the horizontal working platform 10 is divided in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap