Torque detection and transmission device and electric bicycle built-in motor applying torque detection and transmission device

A transmission device and torque technology, which is applied in the field of electric bicycle mid-mounted motors, can solve the problems of increasing the volume and size of the motor, being cumbersome, unable to meet the market demand for miniaturization and light weight, etc., and reducing the cost of the motor and reducing the overall size. Small, reliability-improving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

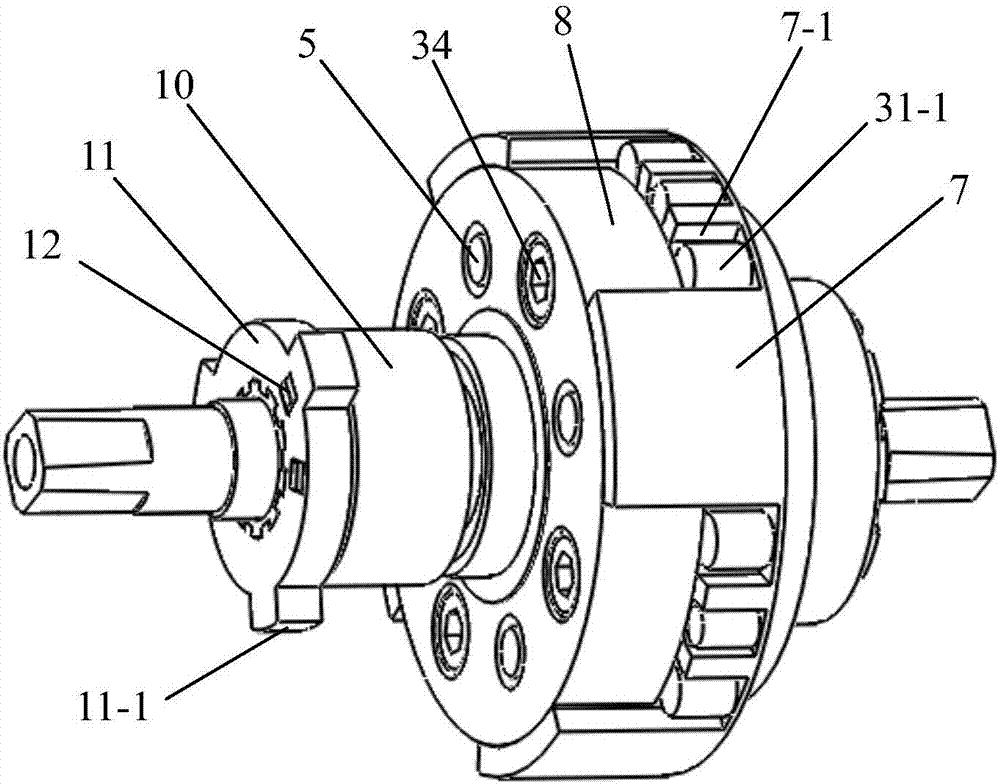

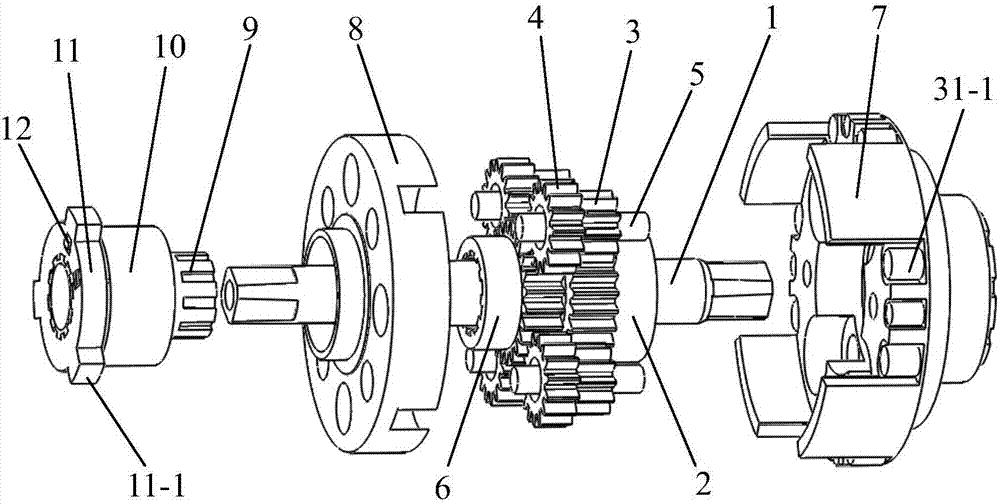

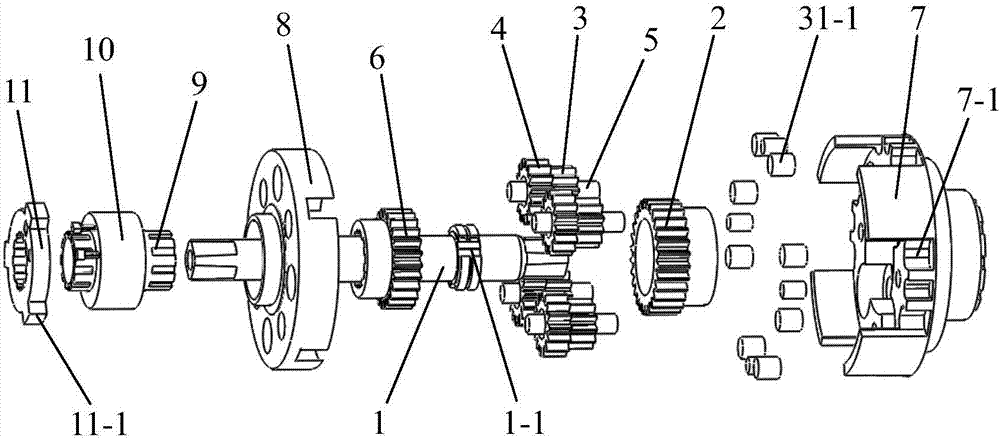

[0027] see attached Figure 7, an electric bicycle mid-mounted motor using a torque detection transmission device, including a motor composed of left and right side shells 25, 26, a main shaft 1, a stator 22, and a rotor 23, and a crankset 21, the main shaft is connected with a torque detection transmission device, so The torque detection transmission device includes an overrunning clutch, planet carrier, left and right planetary wheels, left and right sun gears 6, 2 and a torque signal converter. 34 is fastened into an integral planet carrier, the left and right side planetary wheels 4 and 3 are coaxial gear structures, the right inner end of the right side sun gear is provided with a ratchet 2-1, the main shaft is provided with a jack groove 1-1, and the jack groove There is a jack 36 on the top to form the second overrunning clutch, the right sun gear meshes with the right planetary gear, the left sun gear meshes with the left planetary gear, and the planet carrier is proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com