Sleeve for static-load detection of bearing capacity of permanent pile foundation below bottom of foundation pit

A technology for static load detection and bearing capacity, which is applied in the direction of foundation structure engineering, foundation structure test, construction, etc. Complicated procedures and other issues, to achieve the effect of wide applicability of resources, short construction period and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

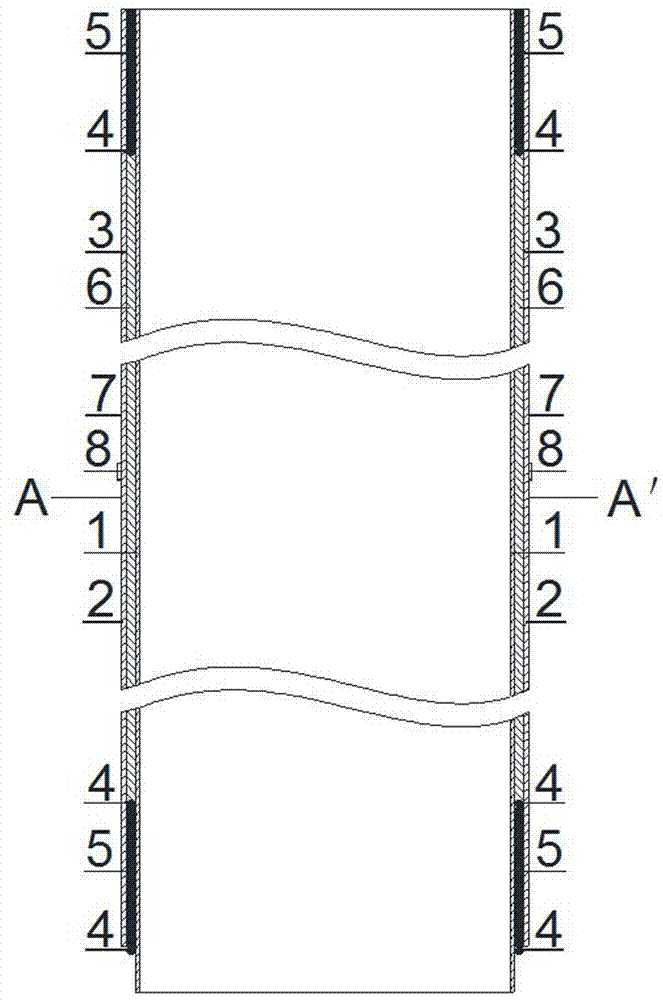

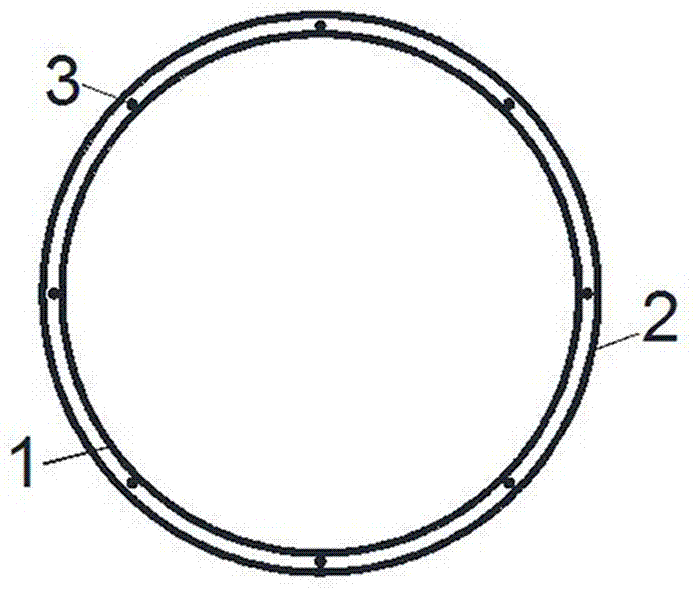

[0020] see figure 1 , figure 2 , the static load testing sleeve of the permanent pile foundation below the bottom of the foundation pit of the present invention includes an inner sleeve 1 and an outer sleeve 2, the upper ends of the inner sleeve and the outer sleeve are flush, and the inner sleeve and the outer sleeve are arranged gap, the lower end of the inner sleeve protrudes out of the outer sleeve to a certain length, and the outer wall of the inner sleeve is uniformly provided with long longitudinal positioning steel bars 3, and the top and bottom ends of the sleeve are provided with waterstops 5, and the waterstops 5 The steel bar 4 is transversely positioned and fixed between the inner sleeve and the outer sleeve, and the gap between the inner sleeve and the outer sleeve is filled with grease 6 .

Embodiment 2

[0022] see figure 1 , figure 2 , the permanent pile foundation bearing capacity static load detection sleeve below the bottom of the foundation pit in this embodiment differs from that of Embodiment 1 in that: there are 3 sets of horizontally positioned reinforcing bars, 1 set is located on the lower side of the upper waterstop, and 1 set Located on the upper side of the lower waterstop, all welded to the outer wall of the inner sleeve, and the other set is located on the lower side of the lower waterstop, welded to the inner side of the outer sleeve.

Embodiment 3

[0024] see figure 1 , figure 2 , the static load testing sleeve of the permanent pile foundation bearing capacity below the bottom of the foundation pit in this embodiment differs from Embodiment 1 or Embodiment 2 in that: the inner sleeve and the top of the outer sleeve use a "U" made of thick steel plate The "U" shaped clips are respectively welded on the inner side of the inner sleeve and the outer side of the outer sleeve, so that the two sleeves form a whole.

[0025] The permanent pile foundation bearing capacity static load detection sleeve below the bottom of the foundation pit of the present invention has grease injection holes arranged vertically and symmetrically at appropriate distances on the outer wall of the outer sleeve, and oil plugs are arranged to match the grease injection holes; the outer wall of the outer sleeve is provided with There are lifting lugs. The lifting lugs are made of thick steel plates. The positions of the lifting points are determined ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com