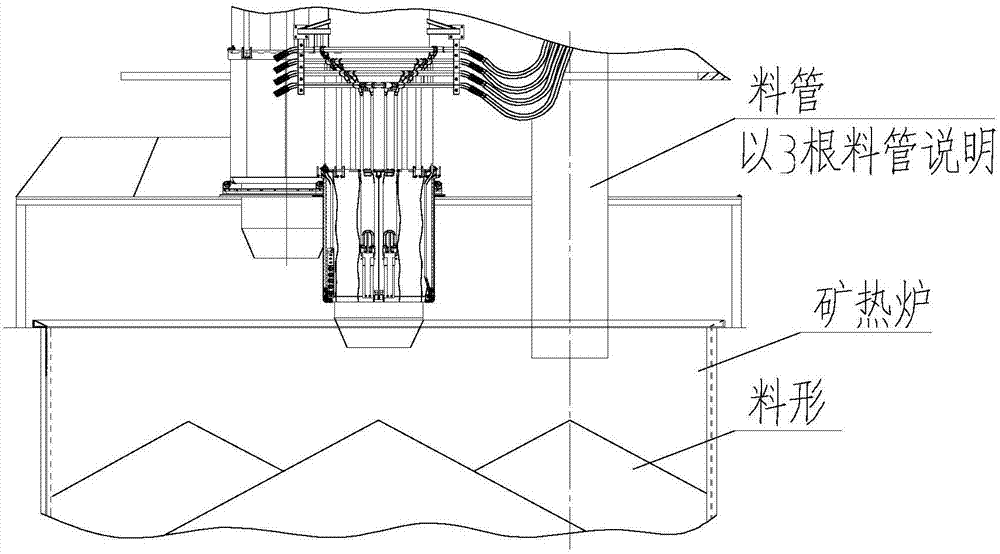

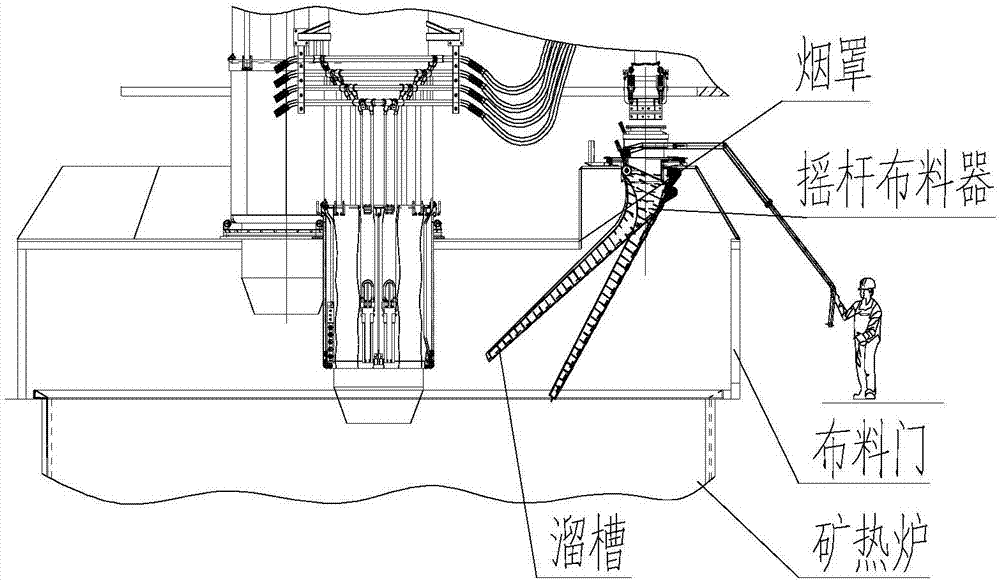

Mechanical transmission submerged arc furnace distributing device

A technology of mechanical transmission and distributor, applied in furnaces, furnace components, lighting and heating equipment, etc., can solve problems such as burning of the head of the material pipe, limited number of material pipes, hidden dangers of accidents, etc., to achieve uniform distribution of materials and reduce power consumption. Energy consumption and the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

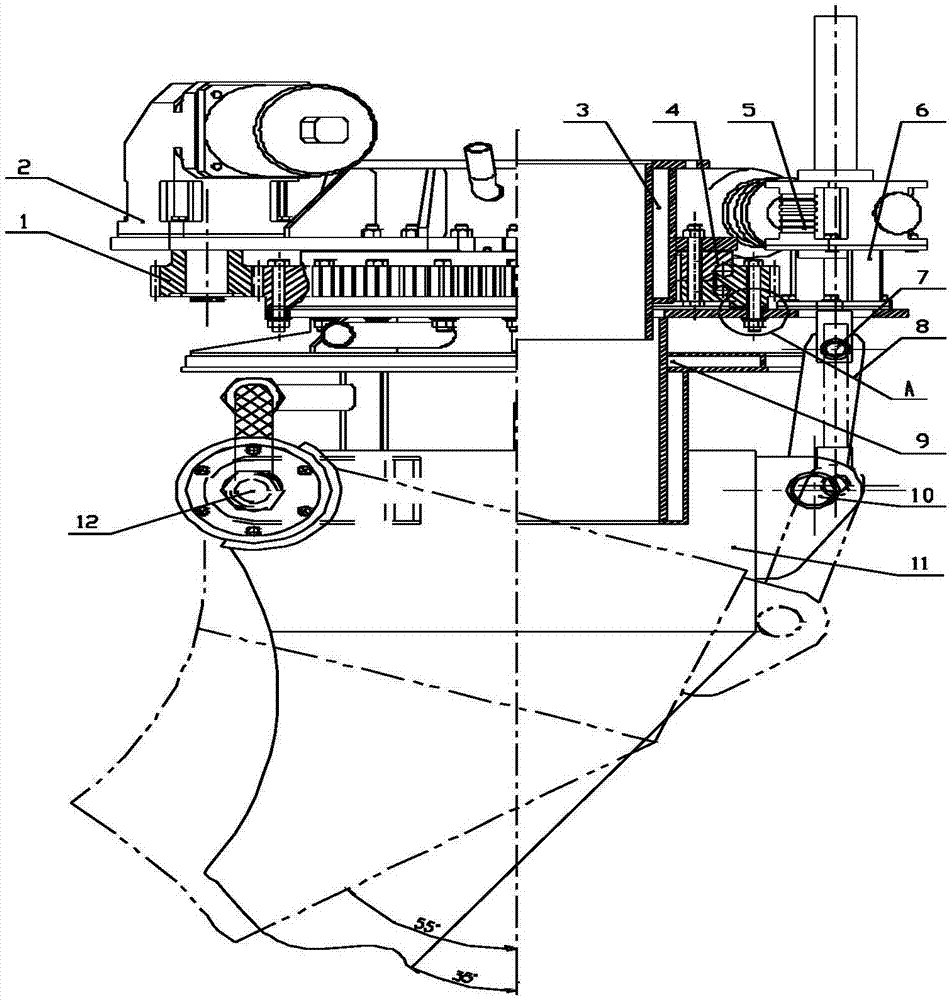

[0019] In order to better understand the purpose, structure and function of the present invention, a mechanically driven submerged arc furnace distributor of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as Figure 3 to Figure 6 As shown, it is shown as a mechanically driven submerged arc furnace distributor of the present invention, including a planetary geared motor 2, a slewing support 4 and a rotary sleeve 9, wherein the planetary geared motor 2 is arranged on the water-cooled central throat pipe 3, and through the bolt Fixed on the steel plate flange in the middle of the water-cooling central throat 3, the output shaft of the planetary gear motor 2 is provided with a pinion 1, and the planetary gear motor 2 drives the pinion 1 to rotate; the slewing support 4 is set on the water-cooling central throat 3, Connect with the steel plate flange in the middle of the water-cooling center throat 3 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com