Subsidiary measuring tool for tape

An auxiliary measurement and tape measure technology, applied in the direction of a bendable ruler, can solve the problems of inability to locate the center of the hole, inconvenient positioning, and inaccurate measurement of the hole distance, and achieve the effect of improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

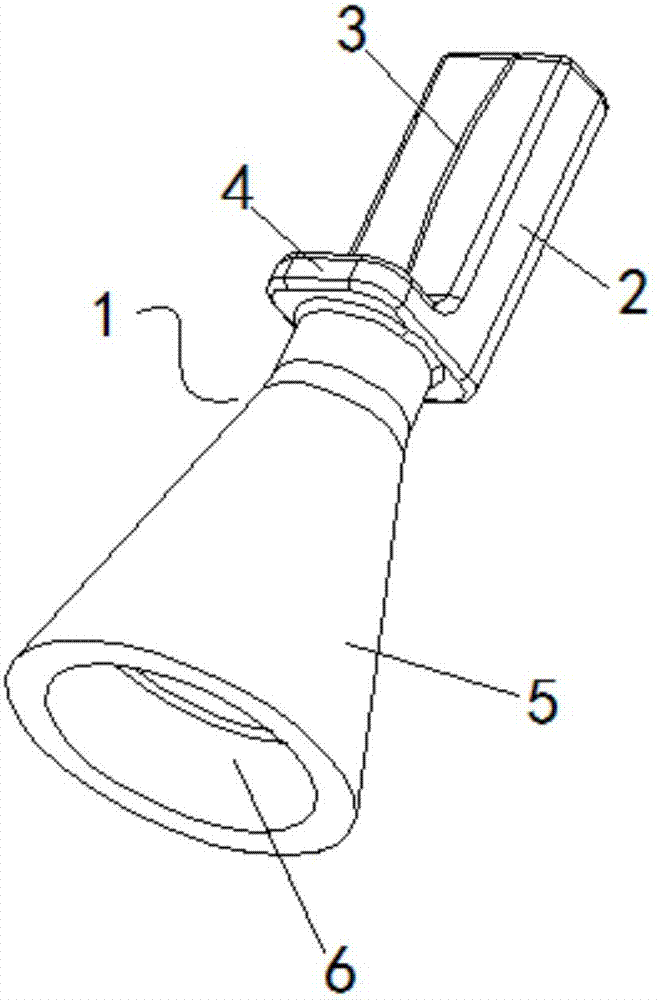

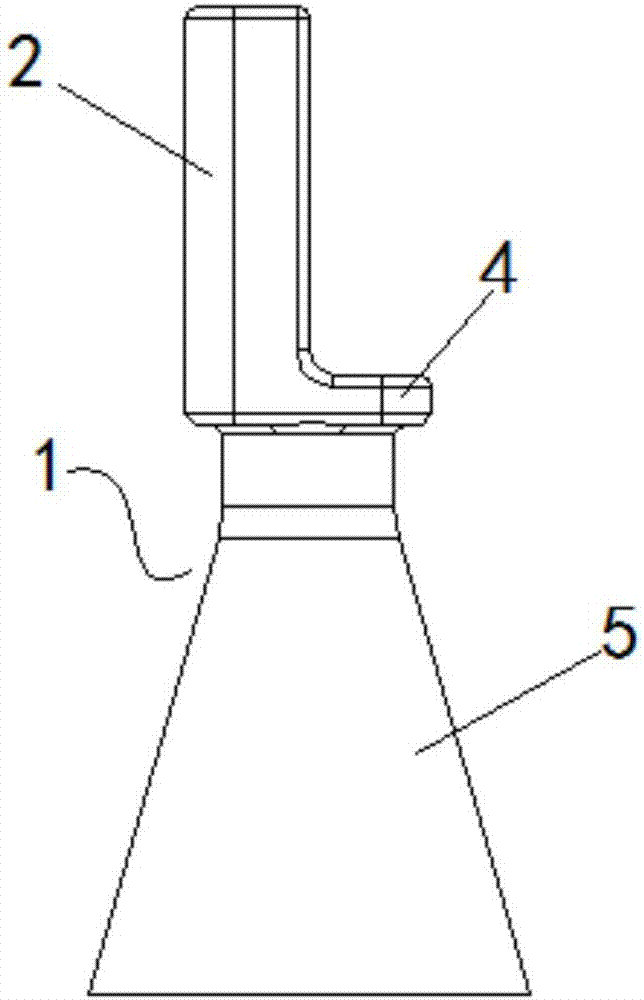

[0040] Please refer to Figure 1 to Figure 4 , figure 1 A schematic structural view of the first auxiliary device in the tape measure auxiliary measuring tool provided by Embodiment 1 of the present invention; figure 2 for figure 1 The front view of the first assistive device in ; image 3 for figure 1 Side view of the first assistive device in ; Figure 4 for figure 1 Cutaway view of the first assistive device in . The specific embodiment of the present invention proposes a tape measure auxiliary measuring tool, which is characterized in that it includes a first auxiliary device 1; the first auxiliary device 1 is provided with a fixing plate 2 for fixing the 0 scale end of the tape measure, and the fixing plate 2 There is a first groove 3 for being passed through by the tape measure;

[0041] The side of the fixed plate 2 is provided with a mounting plate 4, and the side of the mounting plate 4 away from the fixed plate 2 is provided with a first positioning block 5, ...

Embodiment 2

[0048] Please refer to Figure 5 to Figure 8 , Figure 5 A schematic structural view of the second auxiliary device in the tape measure auxiliary measuring tool provided by Embodiment 2 of the present invention; Image 6 for Figure 5 The front view of the second assistive device in ; Figure 7 for Figure 5 Side view of the second assistive device in ; Figure 8 for Figure 5The cross-sectional view of the second auxiliary device in; this embodiment further includes a second auxiliary device 7 on the basis of embodiment 1, and the second auxiliary device 7 is provided with a fixed head 8, and the fixed head 8 is There is a second groove 12 for being passed by the tape measure, the fixed head 8 is provided with a reading hole 13, and the axis direction of the reading hole 13 is perpendicular to the side of the second groove 12; specific implementation , the fixing head 8 is a cylinder with a rectangular cross section.

[0049] One end of the fixed head 8 is provided wit...

Embodiment 3

[0054] Please refer to Figure 9 to Figure 12 , Figure 9 A schematic structural view of the second auxiliary device in the tape measure auxiliary measuring tool provided by Embodiment 3 of the present invention; Figure 10 for Figure 9 The front view of the second assistive device in ; Figure 11 for Figure 9 Side view of the second assistive device in ; Figure 12 for Figure 9 Cutaway view of the second assistive device in . . In this embodiment, the only difference from Embodiment 2 is that the second positioning hole 10 is changed from a stepped hole with a circular cross section to a stepped hole with a regular hexagonal cross section, so as to adapt to different types of nuts. In this way, when a bolt is installed in the hole, it can be positioned directly by fitting the hexagonal stepped hole on the nut.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com