Non-contact adjustable limiting device suitable for punch processing

A non-contact, limit device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as damage to limit parts, mechanical vibration of distance, damage, etc., to avoid damage to equipment and avoid damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

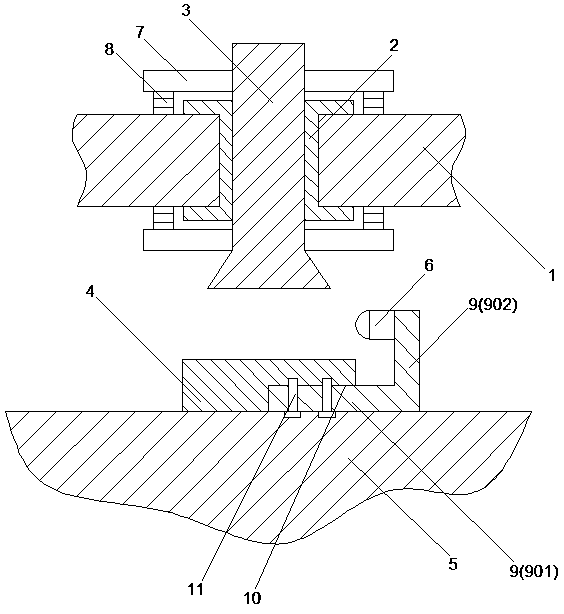

[0015] Such as figure 1 A non-contact adjustable limit device suitable for punch processing is shown, which is arranged on the punching upper beam 1 of the punch; the non-contact adjustable limit device suitable for punch processing includes a fixed The limit nut 2 on the punching upper beam, and the limit stud 3 arranged inside the limit nut 2, the lower end of the limit stud 3 is provided with a limit end body 4 opposite to each other, which is arranged on the punching machine On the workbench 5; the area between the limit stud 3 and the limit end body 4 constitutes a detection gap, and a proximity switch 6 is provided at the side end of the detection gap.

[0016] The non-contact adjustable limit device suitable for punch press processing adopts the above technical solution, which can detect the working state of the limit stud relative to the limit end body through the proximity switch during the stamping process of the punch press; When the proximity switch detects that t...

Embodiment 2

[0018] As an improvement of the present invention, such as figure 1 As shown, the upper end and the lower end of the limit stud 3 are respectively provided with auxiliary support end bodies 7 extending in the horizontal direction, and the auxiliary support end body 7 is opposite to the end face of the punching upper beam 1 of the punch press, and the auxiliary support A plurality of auxiliary support springs 8 are arranged between the end body 7 and the punching upper beam 1 of the punch press. Adopting the above-mentioned technical scheme, it can realize good connection support and cushioning treatment between the limit stud and the blanking upper beam when the limit stud is subjected to limit processing through the setting of the auxiliary support end body and the auxiliary support spring, and then The overall stability of the limit stud can be further improved, so that the limit effect and the limit accuracy can be guaranteed.

[0019] The remaining features and advantages...

Embodiment 3

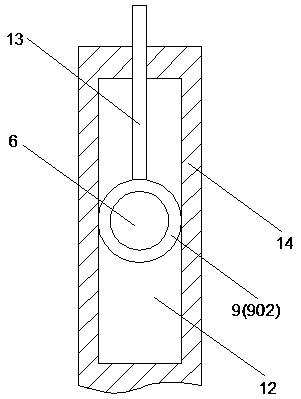

[0021] As an improvement of the present invention, such as figure 1 As shown, the proximity switch 6 is connected to the workbench 5 of the punch press through the placement end frame 9; the lower end of the limit end body 4 is provided with a placement groove 10, which extends in the horizontal direction, and the placement end The frame 9 includes a first part 901 extending to the inside of the placement tank 10, and a second part 902 arranged at the end of the first part 901 and extending in the vertical direction. The proximity switch 6 is arranged on the placement end frame 9 on the second part 902 of the end frame; the first part 901 of the placement end frame is connected to the position-limiting end body 4 through a plurality of connecting bolts 11 . By adopting the above technical solution, it can achieve stable installation for the proximity switch through the setting of the placement tank and the placement end frame, so that the detection accuracy of the proximity sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com