Three-plate-type composite die injection molding machine

A compound mold and injection molding machine technology, applied in the field of plastic machinery, can solve the problems of core board shaking and affecting production, and achieve the effects of reliable installation, increasing efficiency, and stable mold clamping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

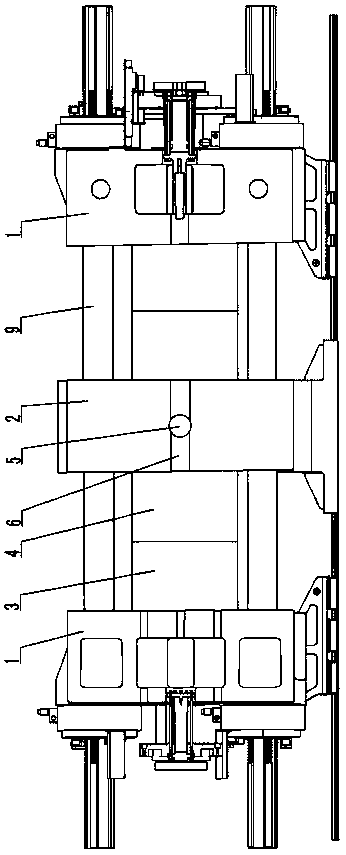

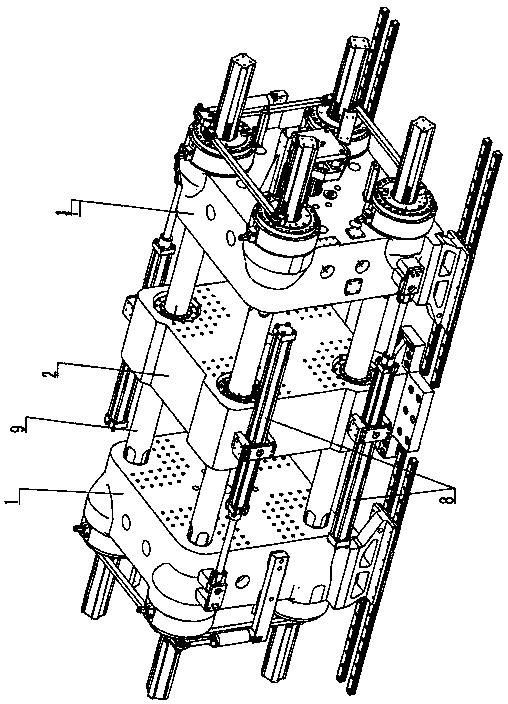

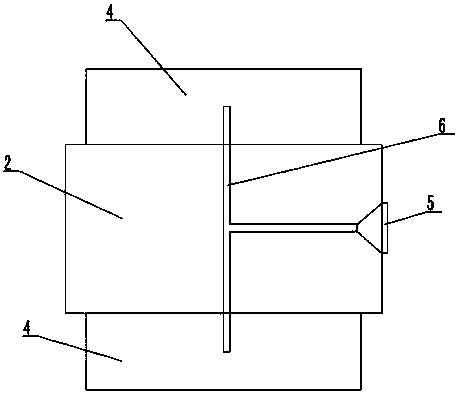

[0010] The invention relates to a three-plate compound mold injection molding machine, such as figure 1 — image 3 As shown, it includes two movable templates 1 and a fixed template 2 arranged on the frame of the injection molding machine, the fixed template 2 is arranged between the two movable templates 1, and the two movable templates 1 and one fixed template 2 are connected by a tie rod 9 Connection, set a core plate 3 of a mold on the inner side walls of the two movable formworks 1, set a cavity plate 4 of the mold on the two side walls of the fixed formwork 2, the cavity plate 4 and the core plate 3 Correspondingly, a side gate 5 is set on one side of the fixed formwork 2, a bidirectional hot runner 6 is set in the fixed formwork 2, the side gate 5 is connected to the bidirectional hot runner 6, and the bidirectional hot runner 6 is connected to two cavity plates 4 . The main feature of this scheme is that two movable formworks 1 and one fixed formwork 2 are arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com