Double-sided reusable templates for semiconductor substrates for fabrication of photovoltaic cells and microelectronic devices

A double-sided, template technology, applied in semiconductor devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Although the present invention is described with reference to specific embodiments, those skilled in the art can apply the principles discussed herein to other places and / or embodiments without undue experimentation.

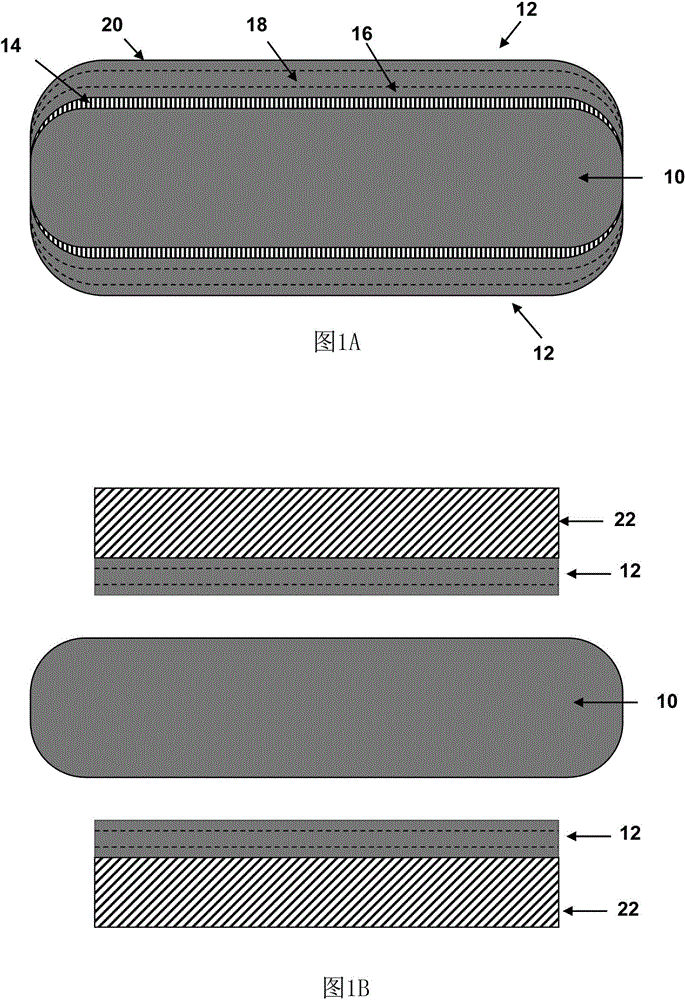

[0028] 1A and 1B show schematic cross-sectional views of the double-sided flat template 10 before and after the TFSS 12 is separated from both sides. As illustrated in FIG. 1A, through an epitaxial silicon growth process, in some embodiments, simultaneously, an epitaxially grown silicon layer is formed on both sides of the planar template and on top of the porous silicon layer 14 on the front and back surfaces of the template. The template may be made of a single crystal silicon wafer with a polished surface (although wafers and / or polycrystalline silicon wafers with an unpolished surface may also be used as templates). The wafer diameter may be in the range of about 150 to 450 mm, and the wafer thickness may be in the range of about 0.5 to 1 mm. Thicker wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com