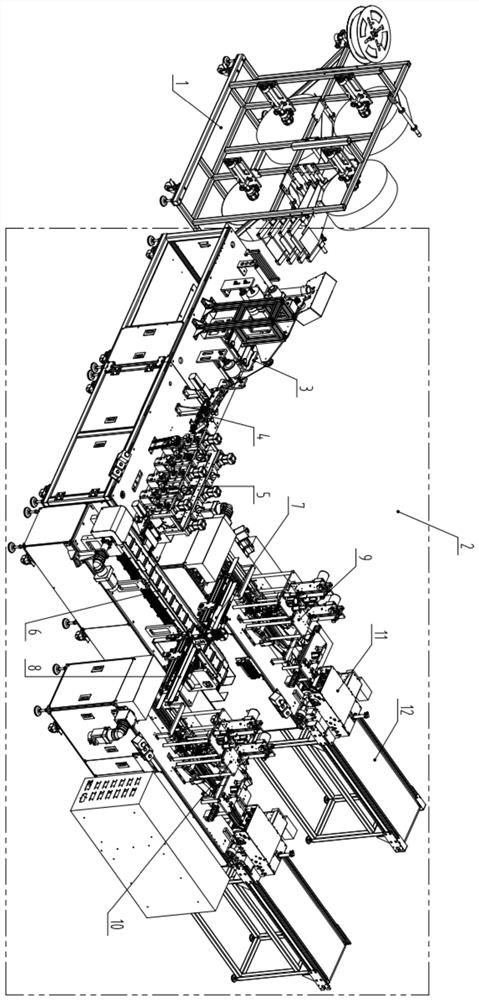

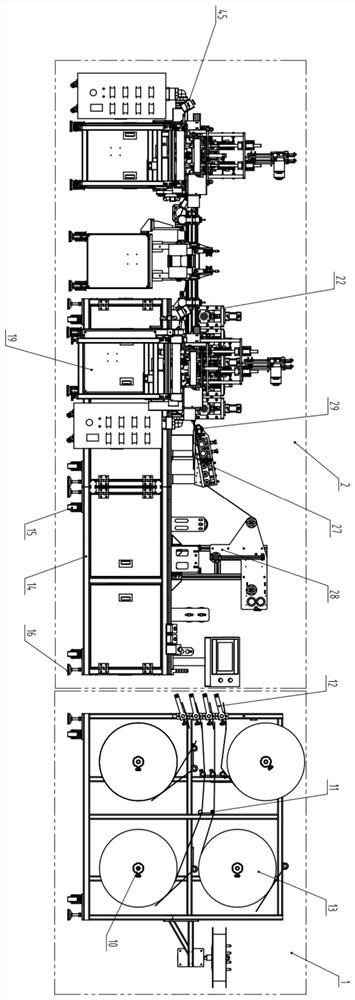

Plane mask (one-driven-two) production line

A production line and mask technology, applied in the direction of sewing tools, protective clothing, clothing, etc., to achieve the effect of high work efficiency and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

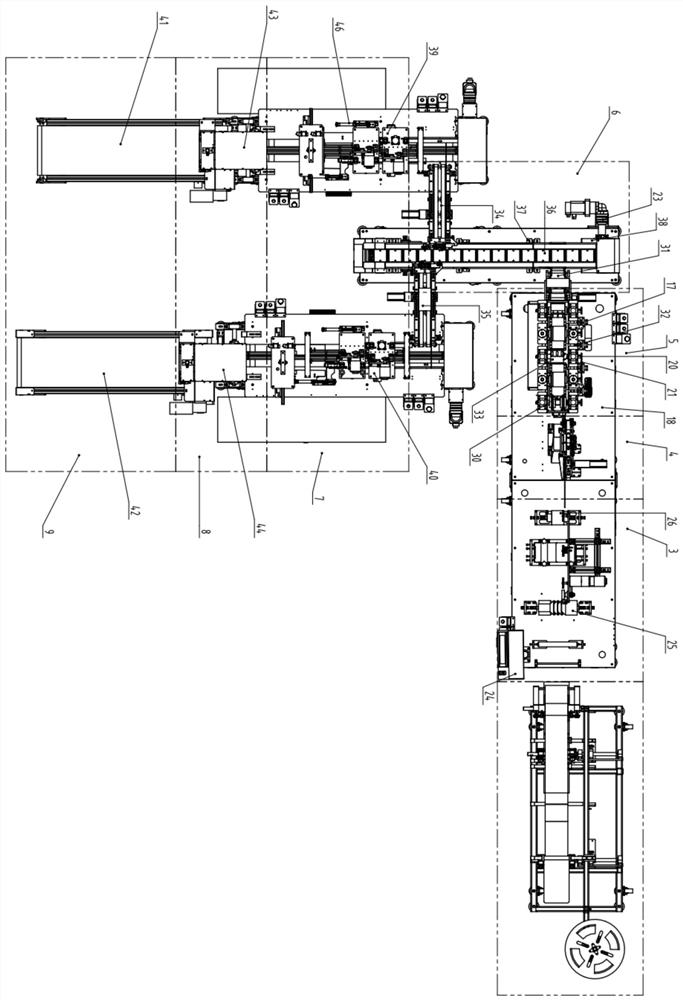

[0029] The earband welding left (39), earband welding right (40), earband welding device (45), and earband cutting device (46) of the earband welding station (7) mainly complete the earband welding on both sides of the mouth. Strip cutting and welding.

[0030] The left earband folding device (43) and the right earband folding device (44) of the earband folding station (8) are fixedly connected to the aluminum platen (18) to complete the inner folding and outer folding action of the earbands.

[0031] The left palletizing device (41) and the right palletizing device (42) of the palletizing station (9) are connected to the machine base (19) to complete the palletizing action of the masks.

[0032] The main shaft (17) is connected with the base (19) through the bearing seat (22), and the motor (23) drives the main shaft (17) to rotate.

[0033] The operation panel (24) is fixedly connected with the base (19).

[0034] Use process:

[0035] Workers can operate the equipment an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com