Marine environment resistant metamaterial substrate and preparation method thereof

A marine environment and metamaterial technology, applied in the field of materials, can solve problems such as poor performance, high cost, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

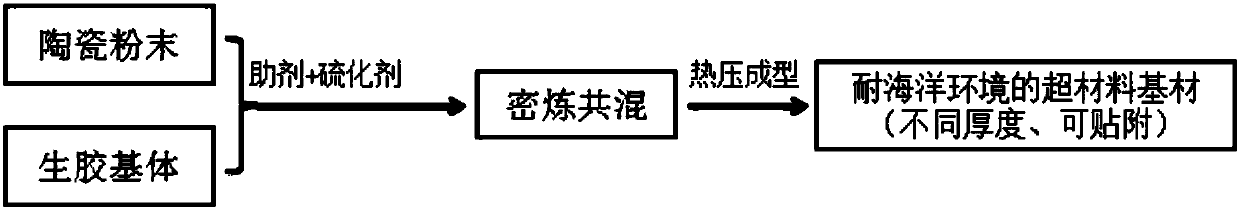

[0029] The method for preparing a marine environment-resistant metamaterial base material provided by the present invention is to prepare a metamaterial base material by mixing ceramic powder and additives in a raw rubber matrix, specifically comprising the following steps: mixing raw rubber, ceramic powder, and vulcanizing agent Blending with additives in proportion; followed by banbury blending and thermocompression molding to prepare the marine environment-resistant metamaterial base material.

[0030] figure 1 It is a process flow diagram of a method for preparing a metamaterial base material resistant to a marine environment according to a preferred embodiment of the present invention. Such as figure 1 As shown, the elastomer powder, ceramic powder, and silane coupling agent are first blended in proportion, and the contents of each component are: 100 parts of raw rubber, 40-330 parts of ceramic powder, 0.7-6 parts of vulcanizing agent and 0.4-15 parts of additives, opti...

Embodiment 1

[0033] After blending 100 parts of EPDM rubber, 40 parts of SiC ceramic powder, 1 part of dicumyl peroxide, 0.5 part of stearic acid, 0.5 part of anti-aging agent and 0.5 part of silane coupling agent, put it into the mixer In the machine, banbury blending is carried out at a temperature of 70°C to make the components evenly mixed; the mixture obtained after banbury mixing and blending is put into a flat-plate hot press machine for hot press molding, wherein the pressure of hot press molding 25MPa, hot-pressed at 170°C for 10 minutes, and dried to obtain a marine environment-resistant metamaterial substrate. The prepared marine environment-resistant metamaterial substrate can have different thicknesses and can be attached.

Embodiment 2

[0035] 100 parts of nitrile rubber, 150 parts of BaTiO 3Ceramic powder and 2 parts of dicumyl peroxide, 1 part of stearic acid, 1 part of anti-aging agent, and 1 part of silane coupling agent are ball-milled and blended in a full-range planetary ball mill. After blending, the mixture is put into a compact In the mixer, banbury blending is carried out at a temperature of 60°C, so that the components are mixed uniformly; the mixture obtained after banbury blending is put into a hot press machine, and hot press molding, wherein, the pressure of hot press molding 20MPa, hot-pressed at 150°C for 30 minutes, and dried to obtain a marine environment-resistant metamaterial substrate. The prepared marine environment-resistant metamaterial substrate can have different thicknesses and can be attached.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com