Whole vehicle high and low temperature test method for new energy vehicle

A new energy vehicle, low-temperature test technology, applied in the direction of vehicle testing, machine/structural component testing, measuring devices, etc., can solve the lack of test simulation methods, the lack of guidance parameters for electric vehicle design and production, and the impact of electric vehicle operating status and other issues, to achieve the effect of high data detection accuracy, convenient vehicle quality, operation stability and reliability, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

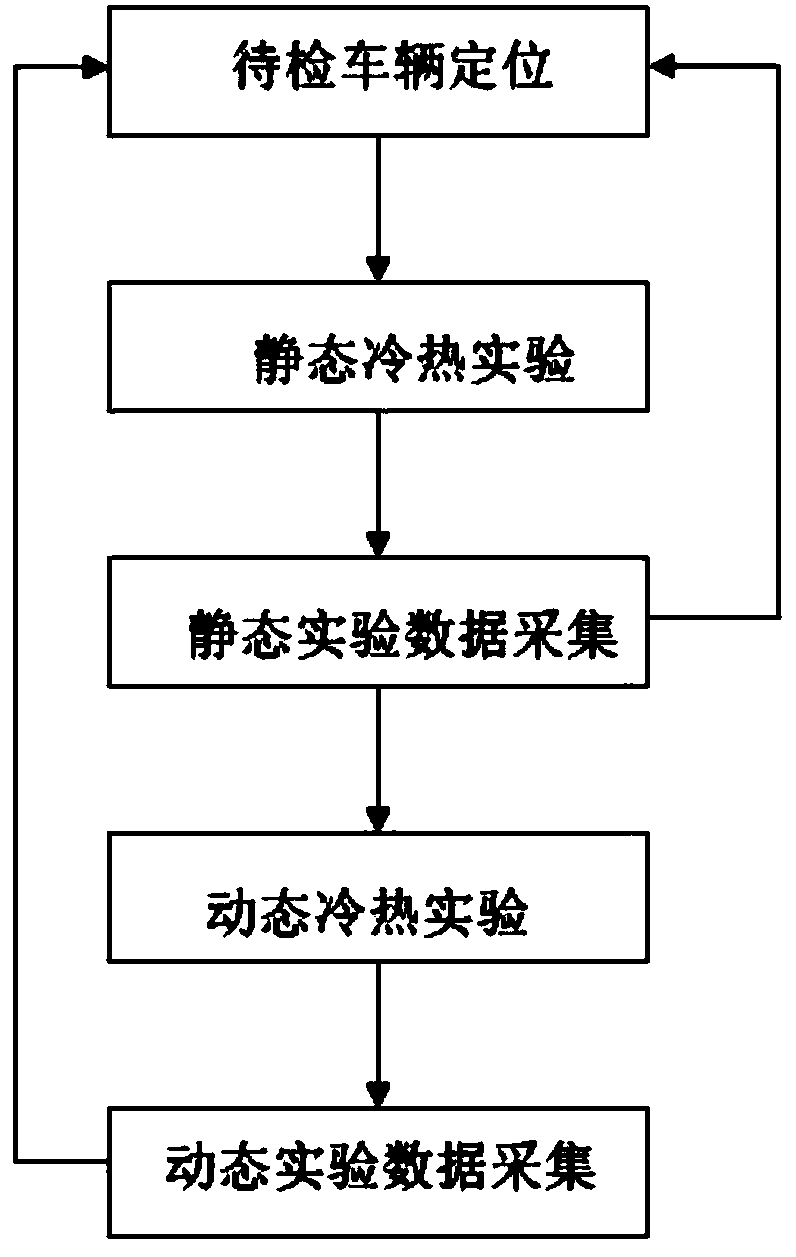

[0029] A new energy vehicle vehicle high and low temperature test method, comprising the following steps:

[0030] The first step is to locate the vehicle to be inspected. Firstly, the vehicle to be inspected is parked in a closed detection space and positioned, and then the detection space is sealed. The distance between the vehicle to be inspected and the inner wall of the closed detection space is 30 cm, so that the vehicle to be inspected All electrical equipment is in standby mode;

[0031] The second step is the static heat and cold test. After the first step is completed, the outer surface of the vehicle to be inspected is irradiated and heated to 70°C within 10 minutes through the inspection space, and kept for 24 hours, and then the temperature of the outer surface of the vehicle to be inspected is naturally cooled. to 30°C, and then the temperature of the outer surface of the vehicle to be inspected will be lowered to 0°C within 15 minutes by the inspection space, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com