Cage hardness testing apparatus

A technology for hardness testing and ball cages, applied in the field of ball cages, can solve the problems of loose clamping, troublesome clamping of ball cages, deviation of measurement results, etc., to improve stability and accuracy, and to facilitate flexible and accurate clamping. The effect of hardness testing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

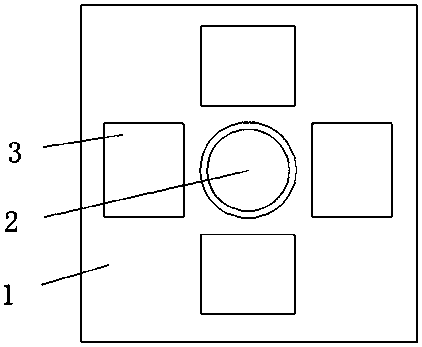

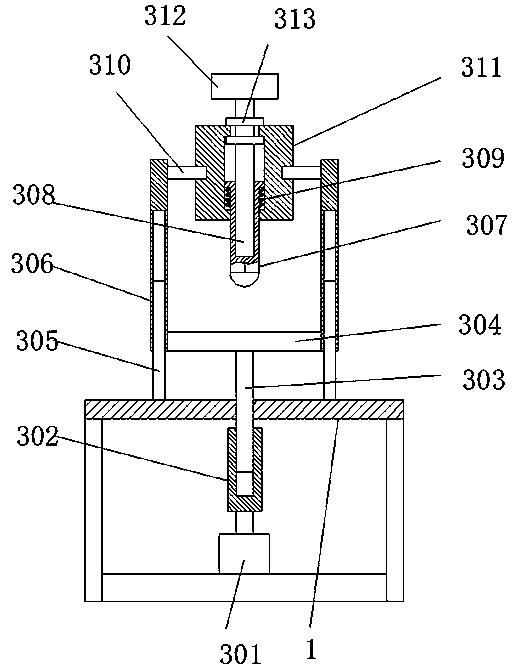

[0018] refer to Figure 1-2 , a hardness testing device for a ball cage, comprising a base plate 1, a bracket is installed on the bottom of the base plate 1, a motor 301 is installed on the bracket, four groups of motors 301 are arranged, and a clamping device 3 and a storage table 2 are installed on the top of the base plate 1 , the top of the storage table 2 is provided with a circular installation groove in section, and the clamping device 3 is provided with four groups, and the clamping device 3 includes a motor 301, a threaded sleeve 302, a first screw rod 303, a lifting plate 304, a guide column 305, Guide sleeve 306, extrusion head 307, second screw rod 308, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com