Two-dimensional code reagent detection carrier, manufacturing method of two-dimensional code reagent detection carrier, detection method of two-dimensional code reagent detection carrier and detection system of two-dimensional code reagent detection carrier

A detection carrier and detection system technology, applied in the field of reagent detection, can solve the problems of ambiguous and inaccurate detection results, uneven antibody solubility, etc., and achieve the effect of enhancing readability and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

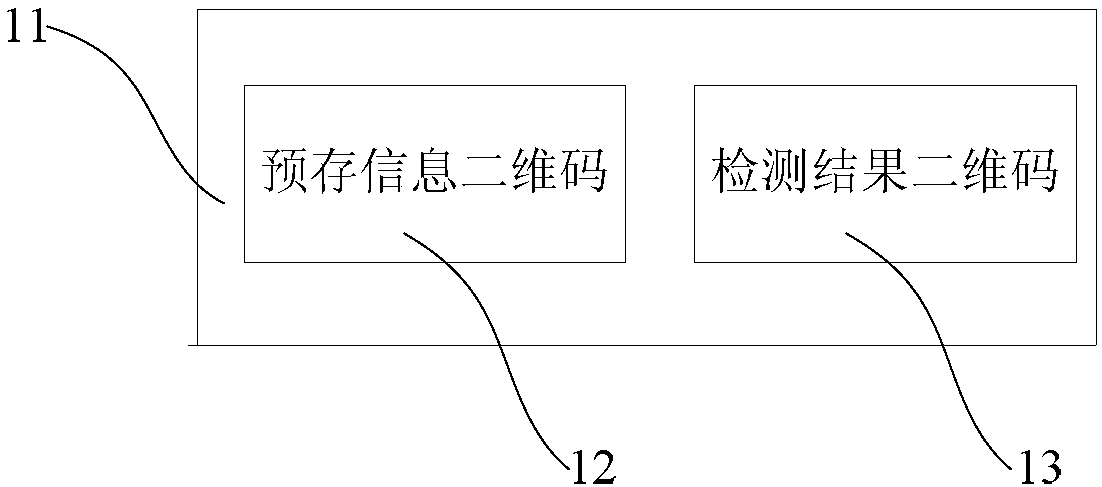

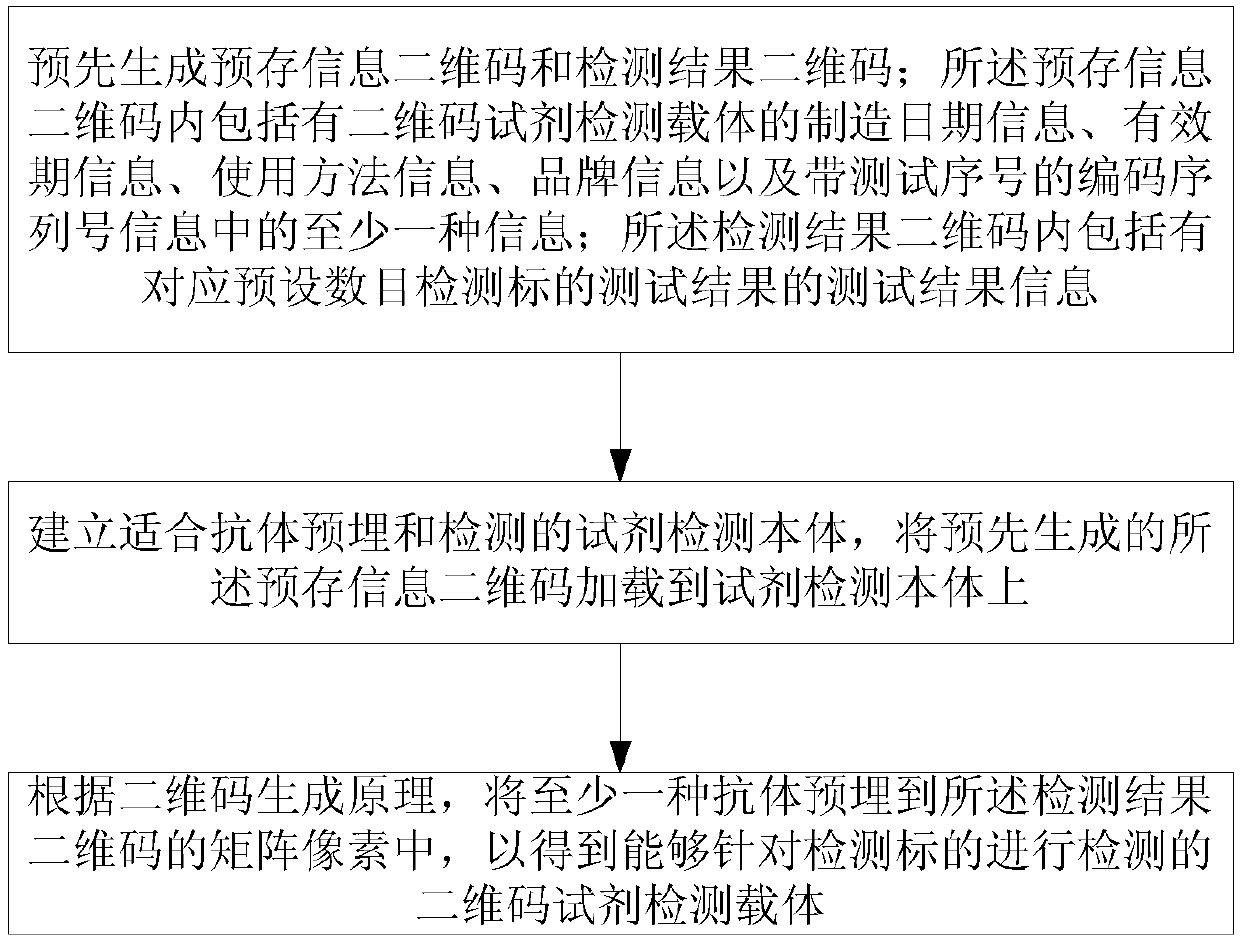

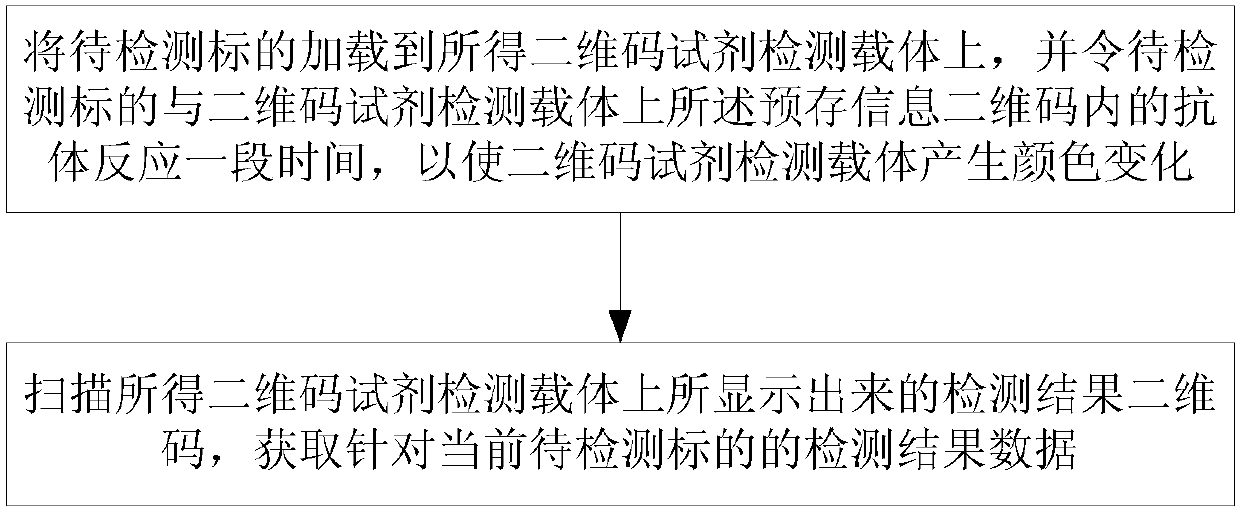

[0038] Such as figure 1 As shown, the two-dimensional code reagent detection carrier in this embodiment includes a reagent detection body 11, and the reagent detection body 11 has a pre-stored information two-dimensional code 12 and a test result two-dimensional code 13, and at least one antibody is pre-embedded in the pre-stored information two In the matrix pixels of the two-dimensional code 12; the pre-stored information two-dimensional code 12 includes at least one of the manufacturing date information, expiration date information, usage information, brand information and coded serial number information with the test serial number of the two-dimensional code reagent detection carrier. The test result two-dimensional code 13 includes test result information corresponding to the test results of the preset number of test targets, and the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com